New tools, approaches meet increased downhole demands

Numerous new drilling, completion, and producing technologies offer a variety of improved approaches that facilitate and lower the cost for recovering hydrocarbons from complex environments at optimal producing rates.

Many of today's fields under development and production lie in harsh climates and deeper water and have reservoirs with such complications as very high pressures and temperatures, low permeabilities, unconsolidated sand, and viscous fluids.

To address these conditions, some new technologies available to operators include a variety of rotary steerable systems, advanced logging-while-drilling (LWD) tools, methods for controlling pressure in the annulus between casings, expandable tubulars, and intelligent completions with fiber-optic sensors.

Rotary steerables

Rotary steerable drilling technology continues to evolve, although the cost of the upper-tier systems for 3D direction control has limited rotary steerables to primarily expensive wells. But lower-cost systems are under development.

Rotary steerable systems allow the driller to rotate the drillstring while building a deviation angle or changing direction in the borehole.

One new alternative, among several, is the rotary steerable technology from Rotary Steerable Tools (RST) Inc., Houston (Fig. 1). The company says that it "has designed, developed, field-tested, and is now commercializing a rugged, simple system that will bring the benefits of 3D rotary steering to the growing number directional wells being drilled today in shallow water, land, and remote environments."

RST describes its tool as short, easy to operate with fewer than 70 discrete components that achieve the desired well plan through use of an electronics monitor and control internal cam offsets. It says that "running and repair costs are extremely low when compared to other systems currently available."

The company recently ran the rotary steerable tool as part of a through-bore-system trial coordinated by Shell Technology Ventures Inc. And RTS says the first run in an offshore North Sea well successfully drilled 2,021 ft in 62 hr while controlling the planned hole inclination and direction.

The RST tool along with other through-bore-system bottomhole assembly components, enable a company to log and run other tools through the bottomhole assembly and bit and out into the borehole. The trials of the through-bore system have included a PDC bit with a removable and reinsertable 21/2-in. ID center insert and latching mechanism, as well as a string of memory logging tools and a removable and re-insertable measurements-while-drilling (MWD) probe type tool.

RTS rotary steerable tools can be run in 143/4 and 121/4-in. holes, and it expects to have versions for 97/8 and 81/2-holes available later in 2003.

Logging-while drilling

Logging-while-drilling technology is catching up with electric wireline measurements, as well as providing innovative ways for measuring in real-time the effects of drilling operations on the borehole. Each time a rig trips drill pipe, logging-while-drilling (LWD) tools can measure real-time formation parameters to obtain a time-lapse view of the borehole.

Although some of these data have been available in the past, companies now are extracting more of these time-lapsed data for such processes as managing the window between pore pressure and equivalent circulating pressure to prevent fluid influx and loss while drilling.

Baker Hughes INTEQ explains that "when combined with conventional surface measurements, as well as more recent technology that accurately measures downhole dynamics (axial, torsional, and lateral vibrations as well as stresses, pressures, torque, and weight transfer efficiencies), we can predict, detect and eliminate problems in the areas of pressure management, wellbore integrity, drilling optimization, and reservoir navigation."

The company says that "New LWD technologies, being deployed now and in the near future, permit more detailed formation evaluation, both as quick-look evaluations as well as very detailed post-acquisition evaluations."

Real-time evaluation of LWD data includes geosteering, the ability to adjust well trajectories to enhance the net-to-gross productive interval. The data allow calculation of the water saturation in a productive formation and comparison of the results with predetermined expectations to determine minimum net-to-gross limits for acceptable well economics.

For example, INTEQ's resistivity logs provide two types of compensated measurement at two different frequencies (attenuation and phase difference at 2 Mhz and 400 khz) at short and long spacings. INTEQ says this capability provides different depths of investigation, various vertical resolutions, and allows correction for anisotropy and dielectric effects. This characterization and advanced modeling allows real-time borehole conditions to be obtained.

One of its new tools is an azimuthal gamma-ray that obtains readings while rotating during drilling. The tool detects the angle and direction of entering beds with its resistivity and directional tool.

The company also has a tool for obtaining azimuthal density image data while drilling for evaluating bed dips, and in some cases fracture swarms, and other formation details.

INTEQ explains that these azimuthal measurements surpass conventional single-curve measurements and can be used for updating geological models and making well placement (geosteering) decisions for production optimization on-the-fly. Its latest tools provide formation pressures, density images, and acoustic compressional, and shear measurements.

It says the acoustic shear velocity measurements are very sensitive to overburden pressure and provide an early detection of overpressured zones before drilling into them. One can use the compressional and shear acoustic data for deriving porosity, abnormal formation pressure evaluation, rock mechanical properties, and thin bed evaluations, as well as seismic time to depth correlations.

INTEQ describes its tools as including a proprietary quadrapole wave generation and measurement that allows for shear wave acquisition even in very slow formations, thus alleviating one of the more difficult problems in using LWD acoustic measurements to identify and take action on potential problem zones.

Fig. 2 shows the excellent agreement of the repeat shear slowness with the original shear log compressional and shear slowness measured with an accoustic LWD tool in very unconsolidated rock (slow formations) in an offshore deepwater environment. INTEQ explains that the quality of the compressional travel time in these slow formations provides an opportunity to acquire, by way of LWD measurements, a compressional slowness where the small amount of time lapse after drilling considerably reduces shale hydration effects.

Shear wave measurements are important for obtaining earth stress information and enhancing wellbore stability calculations.

Acquiring formation pressures while drilling is one of the most exciting advancements in LWD, according to INTEQ. It says these data allow for assessment of abnormal formation pressures even in extended horizontal wells, along with permeability estimations while drilling.

The company says that drilling problems related to kicks, shallow-water flows, and fluid losses, cost operators in excess of a billion dollars each year. To help avoid these problems, pore pressure models from offset well and seismic data used in conjunction with correlations to LWD logs can predict the onset of overpressured formations.

These LWD formation pressure measurements form the basis of calibrating these models in real-time to reduce the model uncertainty, according to INTEQ.

The company says that in addition to being able to model and predict potential drilling problems, the logs can measure more directly the onset of problems in real time while drilling so that corrective actions can be implemented as early as possible.

Because LWD formation evaluation measurements compensate for borehole conditions such as rugosity and washouts, they can, in real-time, indicate the onset of potential hole quality problems.

LWD drilling dynamic measurements also complement early detection of hole quality problems. INTEQ says its new drilling dynamics tool uses calibrated sensors that sample at very high-frequency rates to detect excessive vibrations, stick slip, whirl, bit bounce, and bottomhole assembly bending forces.

By optimizing drilling parameters, one can keep these damaging forces under control to eliminate potential hole problems and bottomhole assembly component failures, according to INTEQ. It also says that these high-frequency drilling dynamics measurements may detect the onset of potential stuck pipe problems by monitoring changes in downhole instantaneous torsional and axial forces.

Casing annulus pressure

One problem faced by operators in deep water is from temperature changes that can generate annular pressure buildup in a sealed annulus sufficient to collapse casing. BP PLC's Gulf of Mexico Marlin TLP project suffered from this phenomenon.

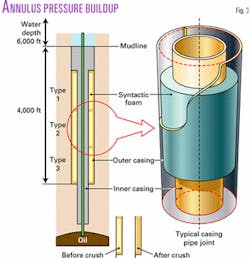

Since that incident, the industry has developed a number of technologies for reducing this problem. These solutions include rupture disks for casing that will burst at a predetermined pressure and temperature threshold, small nitrogen cement spacers that keep pressure lower in the annulus as temperature increases, and syntactic foam that crushes at predetermined pressure and temperature as pressure increases (Fig. 3).

Cuming Corp., Avon, Mass., says that its syntactic foam, which collapses under precisely defined conditions of temperature and pressure, is designed for the deepest wells, in over 6,000 ft of water, and the hottest, at 270° F. and more.

It explains that these well conditions create the challenge of thermally induced pressures in uncemented annuli containing incompressible fluids.

Cuming says that produced reservoir fluids heat the fluids in the annular space, leading to a thermal expansion of the annular fluids.

It says that depending on the wellbore geometry, the reservoir temperature and rate of production, the pressure of the annular fluids can increase significantly to cause an annular pressure buildup.

The company estimates that in some deepwater wells, the pressure increases rapidly at a rate of nearly 30 psi/min to peak values of 6,000-7,000 psi, resulting in the stresses at the mudline increasing significantly on the inner and outer casing walls that form the annulus.

Syntactic foam originally was developed for deepsea buoyancy purposes; however, applications have expanded to such uses as acoustic products, electrical products, and thermal insulation for offshore oil pipelines and equipment.

Cuming describes syntactic foam as made up of tiny hollow glass microspheres, typically 100 m in diameter, that are encapsulated in a matrix of epoxy plastic resin, and formulated for high-temperature performance in the annulus pressure buildup case.

The rigid plastic bonds with and reinforces the glass microspheres, stabilizing the composite structure and creating a material with highly predictable collapse strength, according to the company.

Cuming adjusts the collapse strength of the syntactic foam over a wide range of temperatures and pressures by varying the wall thickness of the glass microspheres and altering the properties of the surrounding resin matrix.

It casts the syntactic foam directly onto the casing OD.

Expandables

Expandable tubular technology has found many applications such as:

- Expandable solid casing that allows the construction of a mono-diameter borehole or function as borehole liners that permit the drilling of larger diameter boreholes.

- Expandable perforated or slotted pipe for lining the producing zone.

- Expandable legs of Level 6 multilateral junctions that permit the drilling of larger-diameter laterals while maintaining pressure integrity with the junction.

- Expandables for use as liner hangers.

- Expandable liners for repairing casing such as a recent work by Wetherford International Ltd. in Imperial Oil Resources Cold Lake field in Alberta.

In this field, Weatherford repaired casing leaks in four wells with its metal-to-metal expanded solid skin system.

It applied the metal skin with its compliant rotary expansion system that forms the metal skin to the casing being repaired and accommodates irregularities within the parent casing. The company says this provides metal-to-metal contact around the entire circumference of the casing and thus provides a tight seal and results in the skin becoming an integral part of the casing string.

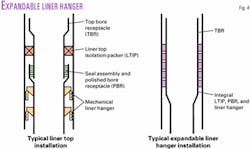

In another use of expandables, Fig. 4 shows how these tubulars can simplify the hanging of a liner. The expandable liner hanger from Halliburton Energy Services has no moving parts, no exposed hydraulic ports, and contains multiple redundant sealing elements.

Halliburton says the liner is available with three to five sealing elements, with a single 1-ft element capable of handling a 500,000-lb tensile load. Its 75/8 in. by 95/8 liner hanger is rated to a 750,000-lb hanging load.

It says that it has installed more than 130 such hangers and that its target markets are deepwater, high pressure, high temperature, and monobore wells.

Intelligent completions

One emerging technology is intelligent completions that include surfaced-controlled downhole flow control. These installations still number fewer than 200, according to various sources, and most are installed in offshore wells, completed either from a platform or subsea.

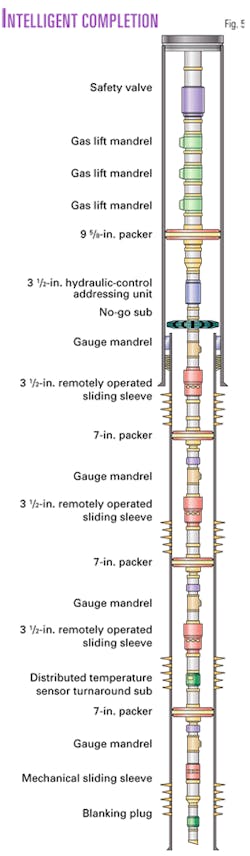

A recent example is a Brunei Shell Petroleum (BSP) installation with a four-zone intelligent completion in its Bugan field, off Brunei (Fig. 5).

Weatherford provided the hydraulically controlled and actuated downhole sliding sleeves for controlling the flow from the producing intervals. The system was installed from an unmanned satellite platform in 131 ft of water.

The system includes feed-through packers, remotely operated sliding sleeves, and an hydraulic-control addressing unit (HCAU) that minimizes the number of control lines required to be run to surface, according to Weatherford. The hydraulic flow control and packer system also was interfaced with multizone pressure-temperature gauges and included fiber-optic distributed temperature sensing.

Weatherford says the overall well objective was the immediate adjustment of zonal production to manage unwanted water inflow, and the combination of permanent monitoring and surface-actuated flow controls allows this to be achieved in a much more timely and cost-effective manner than traditional techniques.