Correlation calculates adsorption capacity of activated carbon for alkyl benzenes in water

Adsorption on activated carbon effectively removes compounds from water. This article presents results for adsorption capacity of activated carbon for alkyl benzenes in water. The results use the Freundlich equation for adsorption capacity as a function of the compound's concentration in aqueous liquid.

An easy-to-use table shows the correlation constants, which makes it useful for rapid engineering data acquisition. Correlation and experimental results show favorable agreement.

Adsorption capacity

Physical and thermodynamic property data for organic oxygen compounds are especially helpful to engineers and scientists in industry. Capacity data for adsorption of organic oxygen compounds on activated carbon is becoming increasingly important in engineering and environmental studies because of more stringent environmental regulations involving water.

This new correlation provides results for adsorption capacity of activated carbon for alkyl benzenes in water. The results are useful for engineering and environmental studies.

Correlation

The correlation for adsorption capacity of activated carbon (Calgon F 400) as a function of compound concentration in aqueous liquid is based on the Freundlich equation:

log10 Q = log10 K + 1/n log10 x (1)

where:

Q = Adsorption capacity at equilibrium, g of compound/100 g of carbon.

x = Concentration in aqueous liquid at 25° C. and 1 atm, ppm (wt).

K = Correlation constant.

n = Correlation constant.

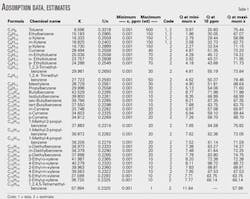

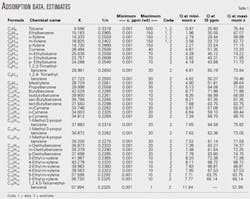

Table 1 shows the correlation constants K and 1/n for various hydrocarbons. The tabulation is based on experimental and estimated values and is arranged by carbon number to provide quick data reference.

The last three columns in Table 1 show adsorption capacity at minimum concentration, 10 ppm (wt), and maximum concentration in water.

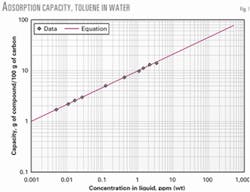

Fig. 1 compares the correlation to experimental data for a representative compound, toluene. Fig. 1 provides adsorption capacity for conditions encountered in water-pollution control. The graph shows the favorable agreement of the correlation with experimental data.

Estimation equation

We conducted a literature search to identify source publications relative to experimental data and property values for estimates when we prepared the correlation.1-5 The appropriate data were saved in a database of adsorption capacity values at different concentrations for which experimental data were available. The database also helped us check the correlation's accuracy.

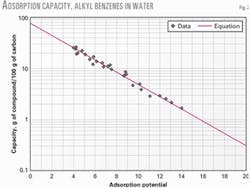

After collecting data, we estimated adsorption capacity for the remaining compounds. For alkyl benzenes, we estimated adsorption from this equation developed from the data of Speth:3

log Q = 1.8893 – 0.1199 T/V log

(xs/x)

where:

T = Temperature, °K.

V = Molar volume of liquid, cu

cm/mole.

xs = Solubility in water, ppm (wt).

x = Concentration in water, ppm

(wt).

For Equation 2, data for density, liquid molar volume, solubility in water, and refractive index are from data compilations by Yaws. 4 5

Fig. 2 shows a graph of adsorption capacity as a function of the adsorption potential, T/V log (xs/x), for alkyl benzenes. The graph is based on data for toluene, ethyl benzene, o-xylene, and m-xylene. The graph shows favorable agreement of the estimation equation and experimental data.

In general, experimental data at concentrations of several hundred ppm are limited. Due to this fact, the estimates are rough approximations.

Also, differences in carbon, water source, and concentration ranges can complicate the adsorption capacity.2

If initial feasibility studies using the tabulated values are favorable, then one should perform follow-up experimental determination of equilibrium adsorption.

Example

Water from an industrial process contains 10 ppm (wt) of toluene: Estimate the adsorption capacity of activated carbon for removing the compound from the water.

Substitution of the coefficients from the tabulation and concentration into the correlation equation yields:

log10 Q = log10 (9.596) + 0.3318

log10 (10) = 1.3139

Q = 101.3139

Q = 20.60 g of toluene/100 g of carbon.

References

1. Sontheimer, H., Crittenden, J.C., and Summers, R. Scott, "Activated carbon for water treatment," 2nd edition, Deutsche Vereinigung des Gas- und Wasserfaches-Forschungsstelle, Engler-Bunte-Institut, University of Karlsruhe, Germany, 1988.

2. Speth, T.F., and Miller, J.R., Journal AWWA, Vol. 72, February 1990.

3. Speth, T.F., masters thesis, Michigan Technological University, Houghton, Mich., 1986.

4. Yaws, C.L., Chemical properties handbook, McGraw-Hill Co., New York, 1999.

5. Yaws, C. L., "Yaws handbook of thermodynamic and physical properties of chemical compounds," electronic edition, Knovel Corp., Norwich, NY, 2003.

The authors Carl L. Yaws is a professor of chemical engineering at Lamar University, Beaumont, Tex. His research interests include technology development, thermodynamic and transport property data, environmental engineering, and process simulation. Yaws holds a BS in chemical engineering from Texas A&I University (now Texas A&M University at Kingsville) and an MS and PhD in chemical engineering from the University of Houston. He is a registered professional engineer in Texas.

Prasad K. Narasimhan is graduate student in chemical engineering at Lamar University. His research interests include thermodynamics, environmental engineering, and process simulation. He holds a BS in chemical engineering from Siddaganga Institute of Technology, India.

Ralph W. Pike is Paul M. Horton Professor of Chemical Engineering and director of the Minerals Processing Institute at Louisiana State University, Baton Rouge. His research interests include process optimization, fluid dynamics, reactor design, ecological systems, and pollution prevention. Pike holds a BS and PhD from Georgia Institute of Technology, Atlanta. He is a member of AIChE and ACS, and is a registered professional engineer in Texas and Louisiana.