Web-based system remotely monitors Saudi wells

A pilot project in Saudi Arabia aims to determine the benefits of remote monitoring technology with an integrated web-based system for lowering operating costs, maximizing production, and ensuring high health, safety, and environment (HSE) standards.

The importance and potential benefits of such a system for Saudi Aramco include:

- Enhancing efficiency in operations by eliminating the need for frequent visits to the well and improving HSE standards by reducing potential hazards.

- Increasing production by providing continuous well information that can be used to foresee problems before they occur.

- Improving reservoir management by providing not only well data but also by integrating information from various data sources for production and reservoir analyses.

- Reducing operating expenses by simplifying and reducing the amount of equipment at the well site.

- Providing web-based data access for the organization that eliminates the cost and need for client software at every desktop.

Conventional technology

Conventional automation and software technology presents many challenges in remote operations systems and production-data management applications. These challenges include:

- Disjointed systems solutions that segregate the well equipment and remote communication hardware from the SCADA (supervisory control and data acquisition) and data management software at the office.

- Systems with a relatively closed architecture that hinder data integration from a newly installed system (green fields) to legacy (brown fields) SCADA systems and historians. Providing hardware interfaces to old hardware at the well sites is another challenge.

- Large number of hardware and software system components such as sensors, RTUs (remote terminal units), wireless communication, SCADA software, data management, and historian software. This requires many companies to be involved in installing such systems, each providing a component of the system.

These challenges increase the cost structure so that it becomes prohibitive to monitor many wells.

Saudi Aramco pilot

Saudi Aramco embarked with vMonitor on a pilot project for remote well monitoring and web-based data integration that currently is undergoing extensive evaluation and testing.

The system includes:

- A wireless remote monitoring system for oil, water injection, and water supply wells.

- A fully integrated end-to-end system from the instrumentation at the well site to the web-based reporting system at the office

- A web-based portal that provides access (real-time and historical data) to the newly instrumented wells as well as a link to multiple production databases and SCADA systems from various vendors.

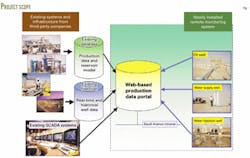

Fig. 1 shows the two major subsystems, which are the remote well monitoring system, and the integrated web-based production data portal.

Its architecture achieves operational efficiency and cost reduction by:

- Reducing the number of complex hardware components at the well site by eliminating the use of traditional electronic flow meters (EFM) and replacing them by alternative technology (such as wireless input-output (I/O) devices) for data acquisition. It also uses a short-hop wireless communication at the well site, especially between the wellheads and cathodic protection that could eliminate the need for installing long (hundreds of meters) cables at each well site.

- Enabling information to be accessed on the intranet, thereby making it available throughout a client's software system with only a web browser.

- Providing a single-point access for production data via a web-based portal for various databases, historians, and SCADA systems.

Remote well monitoring

The pilot project includes oil, water injection, and water supply wells in the same field. These wells are from a few kilometers to up to 20 km from the nearest intranet connection located in the gas-oil separation plant (GOSP).

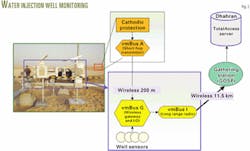

Fig. 2 shows the remote monitoring system that wirelessly transmits the required data points from the various wells to the GOSP. At the GOSP, a master radio receiver is linked via the Saudi ARAMCO network to the vMonitor master server in Dhahran. The server in Dhahran hosts vMonitor's web-based TotalAccess software that provides real-time data on the wells, data-visualization screens, historical reports, and alarms.

Personnel from various departments such as operations, reservoir management, hydrology, etc. can use a web browser to access the data in the field office or at the Dhahran headquarters.

The system polls the data from the various wells at a predetermined interval, but an operator at a server can instruct it to poll data at anytime.

Oil well monitoring

For the oil wells, the monitoring system remotely monitors wells not connected with any distributed control system (DCS) system. The system then wirelessly transmits wellhead data and nearby cathodic protection data to the main server in Dhahran.

The oil well installation includes one temperature and four pressure sensors at the wellhead. The sensors 4-20 mA outputs are connected to a vMonitor wireless data acquisition unit called vmBus, which is a wireless I/O and not an RTU.

The vmBus transmits the sensor data wirelessly to a nearby cathodic-protection station about 150 m from the wellhead. The CP station includes a vMonitor monitoring system for the CP voltage.

The system then transmits the wellhead sensor and CP data wirelessly to the GOSP about 12 km away.

Water injection well monitoring

The monitoring system requirements at the water-injection well involve monitoring normal well parameters such as temperature, pressure, and flow as well as cathodic protection from near the well.

The water-injection well had in place old generation electronic flow meters (EFM).

Saudi Aramco wanted to explore alternative options for measuring flow at the well (Fig. 3) This new approach eliminated the EFM and replaced it with a wireless I/O data-acquisition vmBus that transmits the raw data from the sensors back to the vMonitor Total Access server in Dhahran where all the flow calculations are made.

The system transmits the CP data via a short-hop wireless communication system for more than 200 m to a receiving gateway near the water injection well. In turn, the wellhead data and the CP data then are transmitted to the GOSP (up to 18 km away) and back via the Saudi Aramco network to Dhahran vMonitor TotalAccess server.

The TotalAccess software performs the flow calculations continuously.

Water supply well monitoring

The water-supply monitoring involves interfacing with the water-level sensor that is suspended in the well.

The system transmits the water level to a vMonitor data-acquisition unit that in turn wirelessly transmits the data to the GOSP.

Web-based software, portal

The TotalAccess software provides web-based access to the remote well monitoring system on the Saudi Aramco network (intranet). The system provides real-time well data, historical data, alarms, and performs flow calculations on the water injection well.

The software also provides a web-based portal or data integration hub to various existing databases.

Fig. 4 shows various screens from the well monitoring system. The web-based portal presented some challenging requirements that include:

- Provide data access for newly monitored wells.

- Integration to (and web-enabling of) two existing databases-historians for web-based reporting and data mining.

- Interfacing with existing SCADA systems.

The software allows users to navigate using a single screen and provides web-based data access from these various database systems (Fig. 5). It also has automated certain reports and daily calculations for comparing the monitored data with the central database data (historian data).

The monitored data is collected from the field, whereby the central database system is the master database that contains production data, well data, and reservoir data.

The authors

Mohammed A. Al-Bassam is a petroleum engineering systems analyst for Saudi Aramco in Saudi Arabia. He is a group leader of the producing system unit at the exploration and producing computer center of Saudi Aramco. Al Bassam holds a BS in computer science from Oregon State University.

Hatem Nasr is president and co-founder of vMonitor Inc., Houston. He specializes in developing new generation remote monitoring and web-based data management technology for the oil and gas industry. Prior to vMonitor, he was director of technology at Baker Hughes Inc. and worked at Honeywell Technology Center.