Equipment/Software/Literature

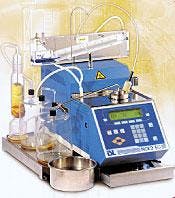

New evaporation loss analyzer

Here's the NCK2 5G, a new generation Noack evaporation loss tester.

It offers precise, automated lubricant testing in compliance with Coordinating European Council, American Society for Testing & Materials, and Institute of Petroleum methods.

The Noack volatility test is used to determine evaporation loss of lubricating oils, an issue of particular importance in engine lubrication. Portions of an oil can evaporate under high temperature conditions, potentially altering oil properties such as viscosity. A low Noack score indicates an oil that will maintain its original protective and performance qualities for a longer time.

These oils perform better under heat, translating to better engine protection, longer oil life, and improved fuel economy, the firm points out.

The NCK2 5G's compact monoblock design helps reduce the amount of bench space previously required for Noack testing, while safe, fume-free operation eliminates need for a fume hood, the company notes.

Advanced technology and features address laboratories' quality assurance requirements, easily integrating into laboratories' existing quality systems. In addition, enhanced versatility helps expand the tester's application base to include waxy products and other oils typically tested at lower temperatures.

Designed for routine work in labs with high sample work loads, the NCK2 5G test initiates with a few simple keystrokes. The test can be started with either a cold or hot heating block.

Smart assistance features automatically alert the operator if any test device is not properly set, and the instrument carefully tracks sample temperature and vacuum throughout the test's duration, providing a digital display of each and recording the values to memory.

Source: Instrumentation Scientifique de Laboratoire, c/o Petroleum Analyzer Co. LP, 300 Bammel Westfield Rd., Houston, TX 77090.

New downhole pump drive head

Here's the new Moyno Ultra-Drive Model CV1 downhole pump drive head.

This electrically driven drive head offers rugged construction and operational features that suit it for medium-duty progressing cavity pump applications. It features polished rod speeds to 600 rpm and a 1,600 ft-lb torque rating on its recoil braking system.

The low profile design helps simplify field mounting and installation, and a removable sealing system permits flexibility and easy maintenance. The CV1 can accommodate either 11/4 or 11/2 in. polished rods.

Other features include:

- Three point lifting design to provide safe, stable lifts.

- Single point belt tensioning system.

- Hinged belt guard that allows unobstructed access.

- Increased thrust bearing capability for long service life.

- Hydraulic backspin retarder for energy dissipation.

Source: R&M Energy Systems, 363 N. Sam Houston Pkwy., Suite 950, Houston, TX 77060.

Free product guide to sealless pumps

A new CD product guide, yours free upon request, presents a full line of Magnatex metallic and Texel fluoropolymer-lined magnetically driven, sealless pumps.

The free guide provides a brief company history in addition to technical information on the complete line of pumps, including performance ranges, specifications, and materials of construction. Liner molding processes for Texel pumps and special testing parameters for Magnatex pumps also are covered.

Suited for nearly any standard or specialized pumping use, their elimination of mechanical seals prevents potential emission problems, while their high strength, rare earth magnetic drives supply no-slip power for operating efficiency and long pump life, the firm notes.

Source: Magnatex Pumps Inc., 3575 W. 12th St., Houston, TX 77088.

New 48 in. knife gate valve made of duplex steel

This new 48 in. knife gate valve is made of high strength 2205 duplex steel instead of standard stainless steel for processing more corrosive and abrasive materials.

The new ferritic-austenitic stainless steel material helps make the valve 50% stronger than austenitic stainless steel valves as well as more corrosion resistant in many uses, the company points out.

For durability in processing and longer life, the valve has a face to face dimension of 6 in. (150 mm) and is designed to be assembled without welding. This virtually eliminates any possibility of preferential corrosion due to influence of welding on the crystallographic structure, the firm says.

Source: Stainless Valve Co., 4811 Persimmon Court, Monroe, NC 28110.