Synthetic-based muds reduce pollution discharge, improve drilling

The US Environmental Protection Agency (EPA) has recognized synthetic-based drilling fluids (SBF) as a pollution-prevention technology, approving the on site discharge of SBF cuttings offshore, provided that operators meet stringent base fluids and cuttings-discharge criteria.1

EPA favored a holistic environmental impact assessment, rejecting the zero- discharge option for SBF cuttings in all offshore locations.

The agency based its decision on increased pollutant discharge that it expected would occur from additional use of water based and oil-based drilling fluids and on nonwater quality environmental impacts that include air emissions, fuel use, land disposal requirements, worker safety, spills, and environmental justices issues.2

EPA rule making

In a "presumptive" rule-making process, EPA issued the regulations by gathering as much information as possible, issuing what it thought were appropriate limitations for the technology, and working with industry and interested parties to confirm whether the initial presumptions were correct.

The presumptive rule making shortened the regulatory process, allowing EPA to issue new regulations in 2-3 years compared to a process that normally takes 5-10 years.

EPA worked with a joint-industry group of operators, service companies, industry organizations, government agencies, and citizens' advisory groups. When additional data indicated the need, the agency made changes to the presumptive rules before finalizing the regulations.3

Kent Satterlee, with Houston-based Shell Exploration & Production Co. (Sepco), said that in its position as environmental subcommittee chair of the Offshore Operators Committee the company worked with an American Petroleum Institute research consortium.

He said Sepco was among the companies leading the industry in providing crucial SBF information to EPA, allowing the agency to make an environmentally sound decision to permit strictly regulated discharge of SBF cuttings.

In January 2001, the EPA published final regulations that establish technology-based effluent limitation guidelines and standards for controlled discharge of SBF cuttings anywhere offshore the US beyond 3 miles.1

The regulations also apply to offshore Alaska but at this time do not authorize SBF discharge within the coastal Cook Inlet.1

EPA Region 6 revised the general permit under the National Pollutant Discharge Elimination System, which became effective Feb. 16, 2002, allowing operators in the western Gulf of Mexico to discharge SBF cuttings for the first time under the new regulations.

The offshore oil and gas industry implements provisions of the general permit through strict base-fluids testing and best-management practices that it applies during drilling operations. The US rules are in the early stage of implementation.4

Taylor Sharpe, with the EPA Region 6 compliance, assurance, and enforcement division, said EPA would have received the first group of offshore-discharge monitoring reports in October 2002 but that the agency had not yet processed the reports.

Nonaqueous fluids

Exploration and development wells, particularly in the mature Gulf of Mexico, are often deviated or directional with high build angles, large horizontal displacements, and complicated well paths. Many wellbore trajectories have rapid build and drop-angle sections and S-shaped geometries.

As drilling operations begin for top well sections, most operators use water-based drilling muds for the large diameter, shallow, and typically straight-hole sections.

Once the wellbore becomes deeper, drilling operations often require muds that offer better drill pipe and borehole lubrication, provide better borehole stability, have better fluid-loss properties, inhibit reactive shales, and yield faster drilling penetration rates than water-based muds.

Oil-based muds provide these benefits; however, diesel and natural crude oils have low biodegradation rates when discharged to the environment and contain highly toxic polynuclear aromatic hydrocarbon compounds. EPA prohibits ocean discharge of oil-based drilling muds.

Drilling mud suppliers and offshore operators have developed SBFs that provide the same drilling benefits as oil-based muds but with much less harmful environmental impact.

Based on vegetable ester and internal olefin chemistry, the SBFs have much higher biodegradation rates than natural paraffinic crude oils. The SBFs, low in polynuclear aromatic hydrocarbons, have much lower toxicity than diesel or crude oil.

John Candler of Houston-based MI LLC said that the offshore drilling industry has been working for formal recognition of SBFs since their first use in the Gulf of Mexico in 1992.

He said the EPA and industry did not envision SBFs when regulations were developed for water and oil-based muds. The testing and regulatory structure in place for these fluids did not fit with synthetics.

Candler explained that, while synthetic fluids made great drilling muds, the industry had to develop environmental tests specifically for SBFs. To allow the industry to continue discharging SBF cuttings, EPA needed tests to demonstrate which fluids were acceptable.

He said that at the discretion of EPA's regulatory enforcement division, the industry discharged SBF cuttings, on an interim basis, within the context of water-based fluid limitations and in a responsible manner.

This was a short-term solution. Candler explained that if EPA at any time felt the industry was not working responsibly, however, it could have required zero discharge immediately, leaving industry with no legal status to counter otherwise.

Operating without regulations specific to SBF hindered the drilling-fluid development process. Candler said drilling-fluid companies were reluctant to develop and introduce new fluids into the Gulf of Mexico market or change the base fluid technology for fear of upsetting the status quo.

Candler said, "Together industry and agency pursued a goal to identify appropriate tests for synthetic-based fluids. It was really exciting because traditionally the EPA has developed the tests and imposed them on industry."

SBF-cuttings discharge

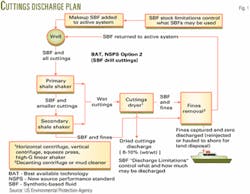

EPA controls SBF-cuttings discharges by strictly enforcing base-fluid stock limitations and controlling the quantity of synthetic fluid discharged with the SBF cuttings.2

Through base-fluid product substitution, EPA regulates sediment toxicity, biodegradation, and polynuclear aromatic hydrocarbons and metals content. In the current regulations, EPA has retained the existing limits for mercury and cadmium in stock barite at 1 and 3 mg/kg, respectively.

EPA prohibits diesel and formation oils discharge and limits the sediment and aqueous toxicity of discharged fluids.

According to EPA, controlling the amount of SBF content in discharged cuttings also controls the amount of SBF discharged to the ocean, affects the biodegradation rate of the discharged SBF, and controls the potential for SBF cuttings to develop cuttings piles or mats that damage the seafloor.

Considering best available technology and new source performance standards, EPA considered the following three options for governing SBF-cuttings waste:

- The industry would use advanced solids-control equipment that would allow controlled discharges.

- The same as the first option but operators would capture fines for no discharge.

- EPA would allow no discharge of cuttings.

Except for the coastal Cook Inlet, where zero discharge is allowed, EPA selected the second option along with various stock limitations. EPA says the option minimizes pollutant loadings to the ocean with acceptable air emissions, fuel use, and land disposal requirements.

Fig. 1 illustrates this cuttings-discharge plan graphically. EPA expected that advanced solids-control equipment would reduce the SBF retention on cuttings to the maximum discharge limits that were set.

A percentage of cuttings, called fines, would have larger surface area per volume and inherently would retain more SBF than the discharge limit. These fines would be captured for reinjection or hauled to shore for land disposal.

EPA's Sharpe explained that in actual practice fines are not defined in the regulations by specific particle size.

He said provided that the solids-control equipment reduces the SBF content below the maximum retention on cuttings and the average retention for all cuttings remained below the discharge limit, then the operator can discharge all of the cuttings.

Satterlee said cuttings dryers often reduce SBF content of cuttings to the 2-3% range. Factoring in the fines, the actual total discharge remains below the discharge limit.

Biodegradation

To develop and use SBFs and to allow workers to determine which fluids are the most biodegradable, EPA and industry required biodegradation tests with good discriminatory power.5

To develop reliable biodegradation tests and gain EPA acceptance, the tests had to be practical, ecologically relevant, and provide repeatable results. The tests also had to be capable of ranking known substances as expected.

Candler said that cost and practicality were very important to industry. "Some of these biodegradation tests were costing $40,000-$50,000/sample. You can imagine if the cost is $50,000 for one sample, it would slow the development of new products," he said.

The industry modified an existing freshwater anaerobic test (ISO/DIS 11734), developed in the UK for sewage sludge to determine the anaerobic characteristics of materials going into domestic wastewater treatment plants.5

Researchers modified the test for use as a marine-sediment anaerobic biodegradation test, which turned out to be the best test among the ones that the researchers considered. Candler said the group did not have a vested interest in any particular test, other than finding a test that the industry felt was the best.

He said the cost has declined to about $2,000/test, which allows industry to run many tests. The bottles are relatively small, allowing many tests in relatively small laboratory spaces.

Maintaining the bottles at constant temperature of 28-29° C., the closed-bottle anaerobic tests accumulate methane gas during biodegradation and pressure in the bottles increases. A pressure transducer and needle device measures the pressure within the bottles, which technicians then plot to monitor test progression.

The base fluid is the primary organic constituent that dominates biodegradation of the mud system. Biodegradation occurs in three phases.

The lag phase occurs as the bacterial population builds up in the system or bottle, the bacteria consume the organic constituents rapidly during the active biodegradation phase, and the plateau phase occurs as the bacteria consume the final biodegradable organics fraction.

Biodegradation tests run for 275 days, which allows the plateau phase to define the test end points. The tests performed in this way yield consistent results.

Candler said the industry observes significant differences in the biodegradation of various base fluids. He explained that tests are run concurrently on many different SBF formulations to evaluate numerous fluids.

Stock limitations for SBF cuttings specify that the base fluid's biodegradation-rate ratio must be less than or equal to 1.

This ratio is the percent degradation of a C16-C18 internal olefin reference fluid relative to the percent degradation of the stock base fluid being tested, in modified ISO 11734 biodegradation tests running for 275 days.

Toxicity testing

To measure the toxicity of water-based muds, technicians expose Mysid shrimp (Mysidopsis bahia) to various mixtures of mud and seawater and measure the lowest fluid concentration that is lethal to 50% of the organisms, which is termed LC50.

Technicians run 20 animals per dish, with three replicates in each test, and calculate the statistics to determine the concentration at which 50% of the animals die after 96 hr. Since Mysid shrimp exist in the water phase, however, these tests are not fully appropriate to address SBFs toxicity.

Candler explained that SBFs are water insoluble and, mixed with solids, form a gelatinous sludge at the bottom. There is very little suspended particulate matter that remains in the water column. Consequently the test organisms are not fully exposed to the test material, which lowers the discriminatory power of the Mysid shrimp test when used on SBFs.

Candler said, "This is good for the environment because these physical characteristics of the discharge reduce potentially toxic components in the water column." Most of the material settles very quickly to the seabed or bottom—the industry needed a toxicity test for the material that settled out.

Candler said the industry has identified a test that employs an organism that lives in the sediment called Leptocheirus plumulosus.

"Our experience in the North Sea showed that the bentitic toxicity tests work best on a class or species called amphipods," said Candler. Amphipods tend to dig around in the sediment and live in the sediment-water interface.

The test procedures are similar to water-based toxicity tests. Rather than 20 Mysid shrimp, technicians put 20 of the amphipods in each test dish and use different concentrations of the mud and sediment. The test objective is to determine the LC50.

Candler said the process sounds simple but the work to develop the tests was quite involved. The EPA and the American Society of Testing & Materials had five or six amphipods that were considered acceptable, which the industry had to evaluate.

Similar to biodegradation, the industry and EPA required tests that would discriminate the toxic fluids from nontoxic fluids in a consistent manner. The tests had to be repeatable, ecologically relevant, and practical.

Candler said that, in the initial test development, MI LLC had tested five of the amphipod species with the standard fluids and had narrowed the best candidates down to two of the amphipods.

He said that others in the industry ran parallel studies, with the results indicating that Leptocheirus plumulosus was the most promising and practical amphipod. It could be grown in the laboratory, it had good sensitivity and discriminatory power, and it liked living in the types of sediments present in the Gulf of Mexico.

Candler said the constituents of the sediments and the nutrients available to the amphipods affect the animals and the test results considerably.

He said if the sediments did not stress the animals and had plenty of nutrients, the amphipods would grow and thrive and the tests would have good discriminatory power.

If the sediment stressed the amphipods, then the tests would lose their discriminatory power. Candler said the industry has been working on man-made sediments for the last 5-6 years that would give consistency to the tests but it's still work in progress.

Stock limitations for SBF cuttings specify that the base fluid's toxicity-rate ratio must be less than or equal to 1.1 2

This ratio is the 10-day LC50 of a C16-C18 internal olefin reference fluid relative to the 10-day LC50 of the stock base fluid being tested.

Best practices

In its efforts to prevent or control leaks, spills, and discharges of toxic and hazardous pollutants in SBF-cuttings waste, EPA has selected a best management practices (BMPs) option that allows operators to choose either a single numeric discharge limitation with an accompanying compliance test method or a set of BMP.1

BMPs are facility specific plans that outline good housekeeping, equipment maintenance and operation, spill prevention and response, inspections, training, and record keeping, to control the discharge of nonaqueous drilling fluid.

According to Sepco, the Noble Jim Thompson rig, while under contract to the company, was the first rig to demonstrate what are now known as BMPs (Fig. 2). The EPA adopted BMPs in its final regulations, published in January 2001, to manage pollution prevention.

Sepco said the Transocean's Deepwater Nautilus, also while under Sepco contract, was the first rig in the Gulf of Mexico to implement BMPs fully.

Satterlee said that Sepco led the industry in meeting EPA's discharge regulations for SBF and associated cuttings in its Gulf of Mexico operations by installing cuttings dryers on its rigs, through development and demonstration of BMPs, and by providing offshore drill locations for a seafloor-survey industry study.

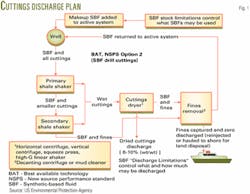

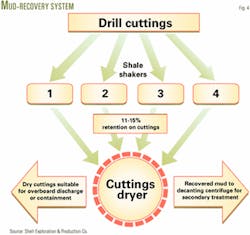

The cuttings drying technology, adapted from the mining industry, is relatively new. The cuttings from the shale shakers, with as much as 15% of the base fluid on cuttings, undergoes as much as 400 Gs of force as either vertical or horizontal centrifugal screens spin at high velocities (Fig. 3 and 4).

Satterlee said the cuttings leave the dryers with as little as 2-3% of the base fluid on cuttings, well below the 6.9% limit that EPA requires for discharge of internal olefin SBF.

He said the new EPA Region 6 general permit now requires that operators use cuttings dryers on all offshore rigs in the western Gulf of Mexico in order to meet the SBF retention on cuttings limit, adopting the standard initially set by Sepco.

Satterlee said that in addition to trained personnel to monitor BMPs and the cuttings discharge process, BMPs involve everyone on the rig.

BMP requires detailed inspection and reporting records for general housekeeping, the rig floor, pumps and mixing areas, the mud pits, fluid transfer, the shale shakers, cuttings dryer, and any fines removal units that may be on the rig.

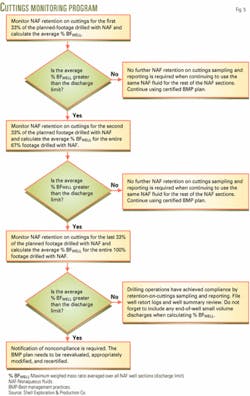

Fig. 5 shows the cuttings monitoring program that the BMP document outlines for the drilling rig Paul Romano, owned by Houston-based Noble Corp.6

References

- US Environmental Protection Agency, "Effluent Limitations Guidelines and New Source Performance Standards for the Oil and Gas Extraction Point Source Category; OMB Approval Under the Paperwork Reduction Act: Technical Amendment; Final Rule," Federal Register, 40 CFR Parts 9 and 435, Vol. 66, No. 14, Jan. 22, 2001, p. 6,850.

- US Environmental Protection Agency, "Overview of Final SBF Effluent Limitation Guidelines," presented to the Gulf Coast Environmental Affairs Group, Mar. 8, 2001, Lafayette.

- Friedheim, J.E., Candler, J.E., and Rabke, S.P., "New Testing Protocols and Regulatory Guidelines to Promote Further Development of Synthetic-Based Fluid Technology," SPE paper 71435, presented at the 2001 SPE Annual Conference, New Orleans, Sept. 30-Oct. 3, 2001.

- Hall, J., "The New Gulf of Mexico National Pollution Discharge Elimination System Permit: How does it Shape Up," SPE paper 77391, presented at the SPE Annual Conference, San Antonio, Sept. 29-Oct. 2, 2002.

- Candler, J.E., Lee, B., Rabke, S.P., Geliff, J.M., Stauffer, R., and Hein. J., "Modification of a Standardized Anaerobic Biodegradation Test to Discriminate Performance of Various Non-Aqueous Base Fluids," SPE paper 61203, presented at the SPE International Conference on Health, Safety, and the Environment, Stavanger, June 26-28, 2000.

- Shell Exploration & Production Co. document, "Best Management Practices Regarding Discharges Associated with Synthetic-Based Drilling Fluids at the Noble Drilling Rig Paul Romano," Sepco D&C, Drilling Fluids & Cement Team and HSE, No. HSE 0121, July 1, 2002.