Horizontal drilling proves zone-specific application in Iranian carbonate reservoirs

The National Iranian South Oil Co. (NISOC), Ahwaz, Iran, has applied horizontal drilling technology to the country's carbonate and sandstone reservoirs to increase recoverable reserves, well productivity, and production efficiency.

The company drilled the first horizontal well in 1992. It drilled 20 horizontal wells in 1993 and by 1999 had drilled 68 horizontal wells in Iranian oil and gas fields.1

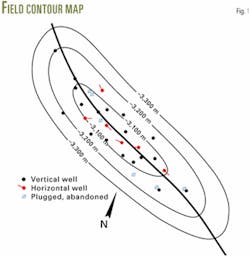

In one application, NISOC evaluated horizontal wells in the Cretaceous carbonate reservoirs of a southern Iranian oil field (Fig. 1).2 The field has upper (reservoir I1) and lower (reservoir II2) carbonate intervals that are separated by an impermeable formation.

A review of well productivity and production history, as well as drilling related events, indicated that horizontal wells are more appropriate for the upper reservoir. Vertical wells should remain the completion of choice for the lower reservoir, II2.

When reviewing reservoirs that are under natural depletion and natural flow, engineers must consider all aspects of well productivity, related not only to the wellbore configuration within the reservoir, productivity index, and formation damage but also wellbore hydraulics and possible use of artificial lift.

Technology incentives

Iran is one of the world's leading energy-producing countries with an estimated 9% of the world's remaining recoverable oil reserves and 17% of its natural gas reserves. NISOC estimates Iran's total oil-in-place at more than 500 billion bbl, with 120 billion bbl of recoverable oil reserves.

The company evaluates new technologies to increase recoverable reserves from existing oil fields and for exploration and discovery of new fields.

Even a modest recovery-factor increase of 1%, for example, of Iran's vast resources would yield more than 5 billion bbl of recoverable reserves. Some technologies promise to increase oil recovery from existing fields by even higher margins, allowing increased production potentials.

More than 90% of Iranian petroleum reservoirs are carbonate (limestone and dolomite) formations. Carbonate reservoirs provide a large share of the world's oil reserves.

From a reservoir engineering perspective, carbonate formations classify as layered and fractured reservoirs that are generally tight; flow conditions for oil within the formation matrix are normally poor.

Compared to highly permeable sandstone reservoirs, carbonates produce their hydrocarbon reserves more slowly. Carbonates that are fractured, to varying degrees, consist of highly permeable fracture networks with tight matrix blocks between.

In addition to successful exploration programs to replace produced or decreasing recoverable reserves, oil companies can further develop existing fields.

NISOC's horizontal drilling effort focused on intersecting natural vertical fractures in carbonate reservoirs and allowing production of isolated reserves.

Other initiatives within the company's horizontal drilling effort were to increase productivity in sandstone reservoirs, increase the performance of enhanced-oil-recovery projects, and enhance overall well and field development economics.

Geology

The southern Iranian oil field of interest is 23-km long and 7-km wide (Fig. 1). First oil production from the field began about 10 years ago from the extensive Cretaceous carbonate reservoirs named, I1 and II2.

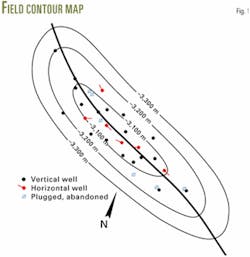

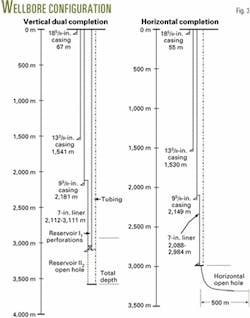

Table 1 lists the basic zonation of the two reservoirs with reservoir I1 about 200-m thick and reservoir II2 about 700-m thick, separated by an impermeable formation.

The field produces oil only from the A2 and B1 members (Table 1).

Geological forces control the reservoir quality. Variations in grain size (primary porosity), bioclast content, the presence of argillaceous material, and subsequent exposure to shallow meteoric waters through subaerial emergence, and later burial diagenesis control reservoir porosity and permeability.

The contribution of primary interparticle porosity and secondary intraparticle porosity varies by zone, with pore size and degree of diagenesis controlling effective permeability. No evidence exists of enhanced reservoir permeability as a result of fracture development in either reservoir.

Both reservoirs are undersaturated. Table 2 lists vapor pressure, gas-oil ratio and other PVT reservoir parameters. Table 3 lists a summary of petrophysical parameters.

Field development

First production from the southern Iranian field began in March 1991. The field currently produces about 45,000 bo/d.

Current reservoir pressures are about 4,500 psi (reservoir I1) and 5,000 psi (reservoir II2). Under natural depletion, engineers estimate the field would continue producing for 80 years.

NISOC has drilled 28 wells—6 wells are horizontal, 7 wells are directional, and 15 wells are vertical. All horizontal wells, except one, are on stream.

The horizontal and directional I1 (highly inclined open hole) wells contribute 3.1% and 3.5% of the field's total average daily field rate.

During its 10-year production history, the field has only reached 10% recovery of original oil-in-place for either formation. Reservoir I1, has produced 70 million bbl of oil and reservoir II2 has produced 60 million bbl of oil.

Fig. 2 shows the pressure history, since initial production, for reservoir II2. The top reservoir shows very much the same pressure trend, declining only slightly more to 4,500 psi.

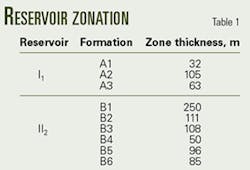

Of the 28 wells drilled, 9 wells produce exclusively from the bottom reservoir (II2), 8 wells produce exclusively from the top reservoir (I1), and the remaining wells produce from both reservoirs simultaneously through dual completions (Fig. 3).

The dual completion wells produce oil from the lower reservoir (II2) openhole completion, through the tubing string. The upper reservoir (I1) produces through perforations in the well casing and flows in the tubing-casing annulus (Fig. 3).

Drilling, completions

NISOC conducted directional and horizontal drilling operations using domestic service companies and drilling rigs. The domestic companies and personnel provided the directional orientation services and drilling technologies that the jobs required, with international service company staff providing assistance in the background.

The personnel adapted existing well design parameters, factoring in production needs, to determine the hole sizes and wellbore configurations for the horizontal wells. The wells normally had 7-in. liners above any openhole sections.

Openhole intervals were the completion of choice for the horizontal and directional wells in this southern Iranian field.

From the kick-off point, the drilling rigs spent 40-60 days drilling the 500-m long horizontal laterals.

During the lateral-drilling operations, the company estimates that drilling mud losses into reservoirs I1 and II2 averaged 400 bbl and 1,200 bbl, respectively.

NISOC drilled only two of the horizontal wells in reservoirs I1 (Wells No. 15 and 21).

Drilling operations encountered numerous problems during the horizontal and directional well programs, with large drilling-mud losses, difficulty with petrophysical logging, and excessively high rig time and cost.

Productivity

Table 4 compares the productivity index obtained from vertical and horizontal wells in the southern Iranian field. The horizontal wells in the top reservoir (I1) saw the greatest productivity index gain at 3.65 times greater than the vertical wells.

The bottom reservoir (II2) saw a much smaller productivity index increase of only 1.24 times greater than the vertical wells.

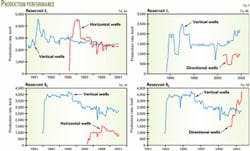

Figs. 4a-4d compare daily production rates for the horizontal, directional, and vertical wells.

Horizontal wells in the top reservoir (I1) showed much greater productivity than vertical wells after initial completion but declined to the same production rate after a few months due to factors unrelated to productivity index (Fig. 4a).

Horizontal wells in the bottom reservoir (II2) failed to match vertical well productivity, since the initial completion, and could be related to the excessive mud losses during drilling operations.

Acknowledgments

The author thanks the National Iranian South Oil Co. for permission to publish this work.

References

- Abdali, M., Horizontal Wells in National Iranian South Oil Company, published by NISOC, Iran, 1998, p. 20.

- Akbarifard, M.G., "Production Optimization in One Iranian Reservoir," Masters thesis, Petroleum University of Technology, Iran, 2002.

The author

Mohammad Jamshidnezhad is a reservoir and production engineer with the National Iran South Oil Co. in Ahwaz, Iran. He holds a BS from Abadan Institute of Technology and MS from Tehran University, both in chemical engineering, and PhD from Tehran University in petroleum engineering. His research interests include production from carbonate reservoirs and enhanced oil recovery processes.