SPE: Government, industry unveil new drill pipe telemetry test results

Government and industry officials announced results from tests of new drill pipe telemetry technology, last month at the Society of Petroleum Engineers annual conference in San Antonio.

They call the new technology a major innovation that will allow high-speed data transmission from the drillbit to the surface during drilling and other operations involving drill pipe.

Researchers have achieved high-speed data transmissions, as high as 2 million bits/sec, through strings of the drill pipe configured with hardwiring within each joint.

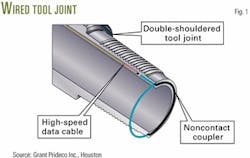

The data signal transfers across each tool joint through noncontacting coils, within the tool joint's threaded connection, which come close to each other when the rig makes up the drillstring (Fig. 1).

Working on the concept since 1997, with funding from the US Department of Energy, Houston-based Grant Prideco Inc. and Novatek Engineering Inc. of Provo, Utah, developed the technology, called IntelliPipe.

The companies have tested first and second generations of the pipe in strings up to 1,000-ft long at a test facility in Catoosa, Okla., and in a test well at Novatek's Utah facility.

Michael Jellison, Grant Prideco's vice-president of product management, said the companies are currently manufacturing a 10,000-ft string of the pipe's third generation, which they plan to test at the DOE Rocky Mountain Oilfield Technology Center in Casper, Wyo.

Jellison said, "The coil in the tool joint doesn't have to make contact, so the pipe is virtually transparent to standard oil field rig operating procedures."

He explained that the companies had tested the connections with various thread lubricating compounds and had even put sand in a connection before making up the joint.

The foreign materials did not affect signal transfer across the joint.

The companies said that, to maintain the signal strength, the system would require battery-powered signal amplifiers at 1,000-ft intervals within the drillstring.

Jellison explained that the system is a distributed network, meaning that it could incorporate various sensors such as pressure or temperature devices within the signal-amplifying units or downhole network nodes (Fig. 2).

Fig. 2 shows the conceptual use of the drill pipe telemetry system, as the developers envision its eventual deployment.

Jellison said, "We still have work ahead of us. If it were just the pipe that were necessary to make the technology commercial, we'd be virtually done. But we're spending time now working on drilling jars, drill collars, and heavyweight drill pipe."

Benefits

Highlighting a list of benefits that the developers think the technology will bring to the oil and gas industry, Jellison explained that two-way, high-speed data transmissions would improve drilling efficiency, enhance drilling safety, reduce well costs, improve profitability, improve bit life, reduce drillstring failures, and reduce drillstring trips.

With high-speed data transmissions enabling a more-advanced generation of logging-while-drilling and even seismic tool technology, the developers explained that the industry would place wellbores within reservoirs more accurately and more readily apply technologies such as underbalanced drilling.

DOE Asst. Sec. Mike Smith commented that, about 25 years ago, DOE held a press conference to announce the innovation of mud-pulse telemetry, which at the painstakingly slow speed of 3-10 bits/sec compares today with IntelliPipe's 1 million bits/sec.