Industry funded project investigates jack up rig spudcan, footprint interactions

A group of 10 oil and gas industry participants that includes operators, contractors, and a government agency have funded a joint-industry project (JIP) to investigate and reduce problems associated with jack-up drilling rig spudcan interactions with footprints in the seabed from prior rig installations.

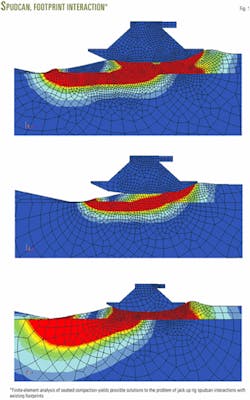

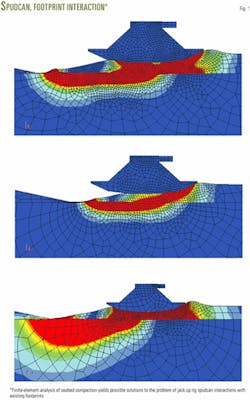

When jack up drilling rigs move onto existing work locations, the companies say there is often a tendency for the rig spudcans to move towards seabed depressions or footprints that prior rigs had created (Fig. 1).

The adverse lateral spudcan movement can cause structural damage to the rig, the platform, and the existing site infrastructure. Spudcan, footprint interactions can result in unsatisfactory rig positioning, often with significant lost time, cost implications, and potentially injury to personnel, according to the companies.

Representing a broad industry spectrum, the participants include BP PLC, Italy's ENI-Agip SPA, Dallas-based Ensco International Inc., ExxonMobil Corp., GlobalSantaFe Corp., Keppel FELS Ltd.'s subsidiary Offshore Technology Development Pte Ltd. of Singapore, ConocoPhillips, TotalFinaElf UK PLC, and Shell UK Exploration & Production Co.

Also a participant, the UK Health and Safety Executive is the health and safety regulatory authority for the UK's oil and gas industry.

An alliance between two UK-based companies, Global Maritime and Fugro Ltd., proposed and promoted the JIP and will conduct the study in a three-phase project.

Project phase one

Philip Wilson, Fugro's business development engineer for offshore geotechnics, explained that in the project's first phase, which began in May, researchers have gathered case histories of jack up installations where spudcan, footprint interactions have created or have the potential to create problems.

After distributing a questionnaire to more than 600 oil and gas industry contacts, both the participants and third parties have responded with information on problematic sites and the details of methods that drillers have used to deal with the problems, according to Wilson.

He added that the Global Maritime-Fugro alliance continues to arrange interviews and meetings, to generate additional responses and clarification on information received.

The questionnaire asked for responding companies' most effective prevention methods and procedures for controlling spudcan-footprint interaction problems and the most effective remediation methods after an interaction incident occurred.

The questionnaire also asked for an indication of the comparative cost implications, either immediate, remedial, or consequential, of such methods and procedures.

The survey asked for technical information on the rig type, spudcan details, and various spudcan and leg spacing dimensions. It asked for environmental conditions such as the water depth, ocean currents, and whether scouring was observed or expected.

The questionnaire asked for seabed soil conditions from geotechnical borehole data, such as the thickness and depth of each soil layer, summary of the soil type, and soil strength or friction angle.

The project proposal explains that, "To our knowledge there have been a large number of spudcan-footprint interaction incidents but understandably there has been a general reluctance for their open discussion, or publication of the circumstances under which they have occurred."

Wilson said the researchers would treat detailed information on actual incidents confidentially, converting it to a generic form for use in the project.

He expects the alliance to finish the project's first phase by yearend, and based on the response received to date, researchers should have gathered and processed the information from 100 responses.

Basically summarizing and documenting how the industry has dealt with the problem, he explained that engineers would present the first-phase findings to the JIP participants in a milestone meeting.

Second phase

The Global Maritime-Fugro alliance explained in an announcement that the project's second phase would investigate spudcan, footprint interaction prevention methods and procedures. Wilson added that the project participants would clearly define the second-phase work details, based on the phase-one research results.

Replies to the questionnaire may add new information to the solutions and remedial actions that the project proposal already highlights for spudcan, footprint interaction problems.

Wilson explains that engineers expect to use nonlinear, large-strain 2D and 3D numerical finite-element analyses and laboratory scale-model testing to analyze for the most problematic soil conditions and determine if current remedial methods are suitable (Fig. 1).

Pharr Smith, vice-president of technical operations for GlobalSantaFe, highlighted that the industry has been dealing with spudcan, footprint interaction problems for a long time and that the key to dealing with it had been ensuring crew awareness of any potential problems and having crews that are experienced in jack up rig placement.

Smith explained that the seabed at some sites is particularly sensitive to jack up rig footprints and the easiest solution is for the operator to ensure that only rigs with the same spudcan spacing work at the location.

Even though it is basically an old problem, he added that with numerical finite-element analyses methods, the industry now has a more sophisticated way of determining how problems can be addressed.

Upon completion of the project's second phase, the JIP would produce a best practices guideline document as the third phase, which should increase jack up platform operational safety by outlining analytical techniques and installation procedures to help identify potential problem sites and mitigating measures the operator could take.

The planned duration for the project is two years.

null