Industry groups working together to 'harmonize' tank measurement standards

The American Petroleum Institute (API), International Standards Organization (ISO), and Institute of Petroleum (IP) are taking steps to "harmonize" petroleum measurement standards.

The three organizations have standards widely accepted in the oil and gas industry. API and ISO standards are usually written by the participating experts from their respective standards institutes but with limited communication with other standards institutes throughout the development stages. The standards thus prepared are often inconsistent on the same technical subject.

API petroleum measurement standards are developed under the auspice of the Committee On Petroleum Measurement (COPM) and published in the Manual of Petroleum Measurement Standards (MPMS). Petroleum measurement standards in ISO are developed under the auspice of Technical Committee (TC) 28, of which the American National Standards Institute (ANSI) is the secretariat.

Since the l990s, a number of petroleum measurement standards in API have been developed in parallel with ISO, or vice versa. An example is the API and ISO standards on automatic tank measurement.

Automatic tank-level measurement

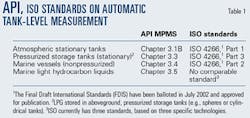

During the late 1980s and throughout the 1990s, both API and ISO developed a series of static measurement standards. Through close communication and years of joint effort, API and ISO are able to harmonize the standards on automatic tank measurement. Table 1 lists the automatic tank level measurement standards developed by these two organizations.

These measurement standards are technically equivalent for custody transfer application. Their core issues are: the accuracy of the measurement equipment demonstrated before installation (i.e., at the factory) and during the initial field calibration-verification, and the requirements for subsequent verification.1

The level and temperature measurement standards reside in two different chapters (Chapter 3 on level, and Chapter 7 on temperature measurement).2 The corresponding ISO standard is the six-part ISO 4266, Petroleum and Liquid Petroleum Products—Measurement of Level and Temperature in Storage Tanks by Automatic Methods.3

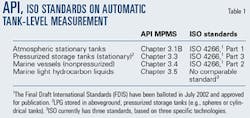

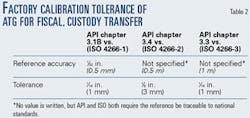

In these standards, both API and ISO have technically equivalent requirements, as shown in Tables 2 and 3.

For comparison, the tolerances in the API standards appear in "customary units" (English units). The tolerances in the ISO standards appear in metric units ("SI units") and in parentheses. It should be noted, however, that the figures in the API standards actually show both units.

In the case of automatic level measurement of light hydrocarbon liquids onboard marine vessels, API Chapter 3.5 (1997) was written to be performance-based. To avoid being too generic, the standard describes the calibration (i.e., "setting") of five commercially available ATGs: electrical capacitance, mechanical float-and-tape, electronic (e.g., magnetic) float, microwave (radar), and hydrostatic tank gauges.

The standard work group wants to avoid writing and maintaining individual standards for these technologies, which is the case in ISO at present.

To be open to new technologies and to avoid being construed as endorsing specific technologies, the standard states that "Marine ATGs that use technology other than those described in this standard can be used in custody transfer if they provide the required accuracy for the intended application."

Manual tank-level measurement

API MPMS Chapter 3. Section 1A, Manual Tank Gauging (1994), is consistent with ISO standard ISO 4512 (2000)4 in many areas, but in a few places the two standards differ.

One area is the accuracy of mechanical steel gauging tape and portable electronic gauging tape. In API, the range of tape calibration tolerance required is 0.01% of tape length, which equates to 0.8 mm (up to 8 m) and 3 mm (at 30 m). In ISO, the accuracy expressed as the maximum permissible error is "1.5 mm for a new dip-tape/weight combination" and "for a dip tape/weight combination that has been in service shall not exceed 2.0 mm in 30 m" (length of tape).

Automatic tank-temperature measurement

The extent of harmonization of automatic tank temperature measurement standards5 resembles that on level measurement. Recent consolidation of various API standards on temperature determination into one document absorbed the technical requirements from ISO (Final Draft International Standards) 4266-5 and 4266-6, both of which have not yet been developed in API prior to the consolidation.

This decision not only ensures harmonization of API and ISO standards, it also saves hundreds of hours of time of the writers and reviewers. Table 4 lists the standards under these two institutes.

These tank-temperature measurement standards are technically equivalent for custody-transfer application. The core issues of these measurement standards are:

•The "intrinsic accuracy" of the measurement equipment demonstrated before installation (i.e., at manufacturer's factory or testing lab).

•The "installed accuracy" demonstrated in the initial field calibration-verification.

•The accuracy requirements for subsequent verification.

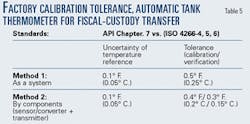

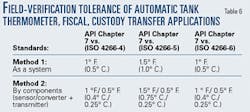

In these standards, both API and ISO have technically equivalent requirements, as shown in Tables 5 and 6.

Although efforts have been made to make the standards technically equivalent, discrepancies may still exist.

For example, a small discrepancy exists on the tolerance of temperature sensor in Method 2. The tolerances in API Chapter 7 and ISO 4266-4/ISO 4266-6 are somewhat different.

ISO derived the required tolerance (0.4° C.) on sensor based on the required overall tolerance of 0.5° C. and the transmitter-converter tolerance of 0.25° C. The corresponding tolerance in API is rounded up to 1° F. from the converted value of 0.7° F. Conversion between the "customary unit" and metric unit (SI unit) occasionally also causes apparent discrepancy due to practicality problems (e.g., on existing field readout devices).

Discrepancies in these standards are due to:

- References to the different standards.

- Different regulatory agencies (e.g., those in the US or in Europe).

- Differences on the application described in the scope of the standard (e.g., for fiscal or custody-transfer measurement only, or for both custody transfer and inventory-control measurement).

Hybrid tank-measurement standard

A recent example of harmonization of API and ISO standards on static measurement is the mutual adoption of the technical enhancements during the development of the "hybrid tank-measurement systems" standard. Hybrid tank measurement refers to the technology of using a level gauge, a temperature-sensing device, and a precision pressure transmitter to measure the mass, volume, and density of the liquid in a tank.6

Improvements from API and ISO were reviewed for adoption between the drafting groups.

At their final stage, the API standard Chapter 3, Section 6 "Measurement of Liquid Hydrocarbons by Hybrid Tank Measurement Systems,"7 and the ISO Draft International Standards (DIS) 15169 "Petroleum and Liquid Petroleum Products—Determination of Volume, Density and Mass of the Contents of Vertical Cylindrical Tanks by Hybrid Tank Measurement Systems" have virtually the same technical requirements on custody-transfer measurement.

It is expected that ISO 15169, when published in 2003, will be technically equivalent to API Chapter 3.6, published in February 2001.

Performance-based standards

The static-measurement standards described previously are perhaps the first "performance-based" standards. Contrary to some of their predecessors (not all have a predecessor), these API and ISO standards are written to avoid being "equipment-specific" or becoming an engineering specification of the equipment.

Where practical, they are written to accommodate more than one technology when multiple technologies exist and they have been proven in the field and with an adequate user base.

This approach allows and encourages faster development and acceptance of new technologies and techniques by the industry, provided they demonstrate the stringent measurement performance set forth in the standards. A drawback of this approach is the exclusion (from the standard) of descriptions of good techniques and installation designs that only pertain to certain measurement equipment and systems.

Due to technical or logistical reasons, however, not all petroleum measurement standards have been, or can be written in this way.

References

- Mei, Kenneth W., "Automatic tank gauges can be used for custody transfer," OGJ, Nov. 13, 1989, p. 81.

- API Manual of Petroleum Measurement Standards, Chapter 3, Tank Gauging (Various chapters published between 1989 and 2001); Chapter 7, Temperature Determination, First Edition, June 2001.

- International Standards Institute (ISO), Final Draft International Standard (FDIS) 4266, "Petroleum and Liquid Petroleum Products—Measurement of Level and Temperature in Storage Tanks by Automatic Methods," June 2002.

- ISO 4512, Petroleum and Liquid Petroleum Products—Equipment for Measurement of Liquid Levels in Storage Tanks–Manual Methods, 2000.

- Mei, Kenneth W., "Accurate, automatic temperature measurement reduces tank volume errors," OGJ, July 20, 1992, p. 105.

- Berto, Frank J., "Automatic gauging technologies have advanced, but better accuracy is needed," OGJ, Mar. 10, 1997, p. 63.

- International Standards Institute (ISO), Draft International Standard (DIS) 15169, "Petroleum and liquid petroleum products—Determination of Volume, Density and Mass of the Contents of Vertical Cylindrical Tanks by Hybrid Tank Measurement Systems," June 2002.

The author

Kenneth W. Mei is a measurement consultant for refining, supply, and distribution with Saudi Aramco in Dammam, Saudi Arabia. Before joining Saudi Aramco, Mei provided technical consultation to clients in Chevron Corp. and its subsidiaries worldwide. He holds a BS in chemical engineering from the University of Southern California.