Wellhead retrieval system speeds subsea abandonment

A tension cut and pull subsea wellhead retrieval system has reduced the time required to abandon subsea wells, according to the service provider Baker Oil Tools.

For instance, James A. Sonnier, Baker Oil Tools marketing manager for subsea tools, estimates TotalFinaElf E&P USA Inc. with the subsea wellhead retrieval system saved 10-12 hr of rig time on a recent plug and abandonment job in more than 4,000 ft of water in the East Breaks area of the Gulf of Mexico.

The job, carried out from the Glomar Celtic Sea semisubmersible drilling rig, cut 133/8-in casing, pulled the hanger, set a hydraulic spear, and recovered the casing in one trip. In a second trip, the job included engaging the wellhead and cutting two strings of conductor casing (20 and 36 in.) in less than 11/2 hr.

In another example, he says a major operator working from a floating vessel in the North Sea cut 20 and 30-in. strings of conductor casing in less than 2 hr and recovered the wellhead from the seafloor in a single trip.

Sonnier estimates this job would have required two or more trips with conventional cutting and recovery tools.

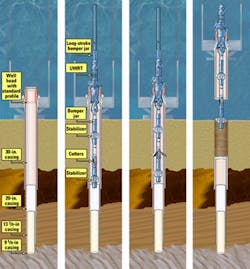

Baker's retrieval system consists of a four-component fishing tool designed to keep the workstring in tension during cutting. Sonnier says the ability to cut in tension creates less pipe fatigue on the workstring while also providing a more efficient cut.

Another uniqueness to the system is the procedure sequence that cuts the casing before extraction of the casing hanger seals, according to Sonnier.

Well retrieval system

Sonnier describes wellhead recovery systems before the development of the multifunction fishing tools as very time-consuming and thus, cost intensive.

He indicates the jobs, typically, required three or more drillpipe trips for removing each intermediate casing string.

For instance, each intermediate casing string required a trip to recover the casing hanger seals from the wellhead, a second trip to cut the casing, and a third trip to remove the casing and casing hanger from the well.

Following recovery of each intermediate casing string, the next step entailed cutting the conductor strings just below the mudline and recovering the wellhead.

Sonnier says during the past decade, advances in cut and pull technology have consolidated cutting and recovery of the wellhead into a one-trip procedure, but the jobs still required multiple trips for each intermediate casing string.

Rig time consumed by these trips is a function of water depth. Sonnier indicates that 8-10 hr round trips plus additional time for cutting are common.

He says conventional cutting equipment often requires 7-10 hr for cutting large-diameter, 20-36 in., thick-walled, 11/2-in. conductor casing that ties into subsea wellheads.

With $250,000/day or greater deepwater rig rates, he estimates the potential savings from eliminating one trip can be more than $75,000.

Wellhead retrieving tools

The Baker subsea wellhead retrieval system has a universal wellhead retrieving tool (UWRT) that combines a latching tool with a marine swivel (Fig. 1). Sonneir says this is an important advantage over earlier wellhead recovery tools because the UWRT can engage and recover any manufacturer's subsea wellhead with only minor reconfiguration.

Previous tools relied on wellhead-specific adapters to engage proprietary profiles on the wellhead housing or on wickered slips to engage the wellhead bore. He says these tools required precisely mated engaging hardware for a variety of wellhead designs and the slip-style engagement posed the risk of damaging the polished bore.

The UWRT has a collet system that engages a shoulder beneath the wellhead polished bore in tension. A J-slot in the top of the retrieving tool controls the setting and releasing of the collet from the wellhead.

One runs the tool with the J-slot latching the collet in the release position. After it is shouldered on top of the wellhead, a one-quarter turn to the left releases the inner mandrel from the run-in position and raises it, locking the collet into the wellhead. Once locked, one can overpull on the drillstring.

If the tool string has to be recovered prior to completely severing the wellhead, one can disengage the tools from the collet by slacking off on the drillstring. Lowering the inner mandrel automatically reengages the J-slot to maintain the collet in the released position.

Sonnier says once set in the subsea wellhead, the UWRT allows tension to be maintained on the workstring during the cutting process, with the thrust bearings rated for an overpull up to 300,000 lb during rotation while cutting the pipe.

The tool is rated for 1.24 million lb of static pull to recover the wellhead, which may be seated to the seafloor with considerable friction.

The tool includes a multistring cutting tool fitted with knives of sufficient length to cut both 20-in. casing below the wellhead and 30 in. or larger conductor string pipe strings.

During the cutting, the cross section of pipe being cut increases substantially, and therefore the force applied needs to increase as the cut proceeds. This is accomplished by increasing the fluid circulation rate that in turn increases the differential pressure across the piston in the cutter and the force exerted against the knives.

Intermediate casing string

The multistring cutter for severing the conductor casing also can cut the intermediate casing strings, according to Sonnier.

The tool has knives of different lengths that can be interchanged to cut a single pipe string or to cut multiple strings progressively. An adjustable surface indication verifies that a cut has been made.

He says the intermediate casing string recovery tools include a hydraulic casing spear and a combination marine swivel-hanger seal extractor. The hydraulically operated casing spear can be set and released without rotating the pipe. The spear is run one joint above the cutter to eliminate the need for stripping operations once the casing is set in the slips on the rig floor.

The marine swivel seal extractor allows the casing cut to be located with precision and maintains the multistring cutter in a stationary position during cutting operations. The tool's design allows the casing string to be cut with the hanger seals locked into the wellhead, preventing hanger movement that could scar the inside of the wellhead. After cutting, the seals are unlocked and retracted, allowing the hanger to be pulled and recovered in the same trip.

Motors, explosives

The tension cut and pull system uses rotary drilling and does not require downhole motors or explosives. Sonnier says avoiding explosives enhances safety and reduces the risk of damage to the subsea habitat. Also, he adds eliminating downhole motors reduces costs associated with equipment and breakdowns, enhances operational reliability, and optimizes cutting efficiency.

Systems with downhole motors also use hydraulically operated cutters similar to Baker's multistring cutter, according to Sonnier.

In these systems fluid circulation at a prescribed rate operates the cutter. For a single string cut, the fluid requirement does not vary significantly during the cut. Cutting two or more casing strings, however, requires one to increase differential pressure as the cut progresses.

Sonnier says the benefit of using rotary drilling it that the cutter rotation is independent of fluid circulation rate; therefore, one can vary both the rotation speed and the circulation rate independently to maintain the optimum cutter velocity, torque, and cutting pressure against the pipe.

He contrasts this to downhole motor systems that have a rotary speed, available torque, and cutter force that are all dependently linked to the circulation rate. Consequently in these systems, he says it is more difficult to optimize cutting parameters.