Correlation predicts pressure drop in gas-condensate pipelines

A simple, easy-to-use correlation has been developed to estimate pressure drop in gas-condensate pipelines. The research is based on data from Iran's Kangan gas-condensate field.

Gas condensation is common in natural gas pipelines, but a simple-to-use correlation has been needed to estimate pressure drop accurately in preliminary design calculations of these pipelines.

Furthermore, in existing pipelines, changes in flow parameters and conditions result in a change in the pressure drop in the pipe.

The aim of this study is to develop a simple correlation based on existing data from Kangan gas field for the pressure drop estimation in gas-condensate pipelines.

Other methods

There are two techniques generally used in the design of two phase, gas-condensate pipelines: the single phase safety factor (SPSF) and steady empirical two phase (SETP) methods.

There are subcategories, however, in each of these groups. The categorization is based on the general characteristics of the models in the groups. These are not covered in depth here but can be reviewed elsewhere.1 2

SPSF designs were commonly used in the early years of wet-gas pipelines. These approaches essentially rely solely on the well-established design equations for single-phase flow in pipes.

Two-phase flow is treated as a simple extension by use of a multiplier, a sort of safety factor to account for the higher pressure drop generally encountered in two-phase flow. This heuristic approach has been widely used but generally results in inaccurate pipeline designs.3-5

When the amount of the condensed liquid is negligible, use of an SPSF approach could at best prevent under design.

More often than not, however, the quantity of the condensed liquid is significant enough for the SPSF approach to be extremely erroneous.

The inadequacy of the SPSF methods led researchers to devise better design and predictive models for two-phase flow systems. These efforts led to the development of several empirical and semiempirical models to describe rather complex flows.

Many of these correlations (the SETP approaches) are based on flow regime for estimating the two-phase friction factor, which is then used to estimate pressure drop.

While some of the correlations predict pressure drop reasonably well, their range of applicability is limited, making their use as a scale-up tool inadequate. This fault is understandable because the database used in developing these correlations is usually limited and based on laboratory-scale experiments.

Another plausible source of their inadequacy is that most SETP methods are based on the premise that the flow is homogeneous; that is, the correlations treat the flow properties as representing a mixture rather than the individual phases. The Lockhart-Martin elli,6 Eaton,7 Beggs-Brill,1 and Taitel-Dukler8 SETP correlations are the most popular.

While it is indeed remarkable that some of these models can adequately handle no condensing, two-phase flow, they give erroneous results for gas-condensate flow.3, 9-11

Furthermore, many of the SETP and SPSF models give widely conflicting results, making the design choice even more difficult. Various in-depth comparative analyses of the available SETP and SPSF models have been reported.2 4

Although the contribution of the available SETP models to the predictive and design capability for no condensing two-phase, gas-liquid flow in pipelines is recognized, the general consensus seems to be that an acute need exists for more reliable, versatile, and flexible models, especially for gas-condensate systems.

Analysis

An earlier experimental pilot study with an air-water mixture9 indicated a significant ordering of data with a combination of Reynolds and Froude numbers.

In the study, this ordering was used for developing the pressure-drop correlation based on the data of the Kangan gas-condensate transmission pipeline.13

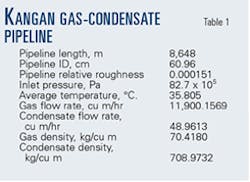

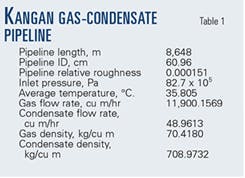

Table 1 reports the Kangan gas-condensate transmission pipeline data needed for all the runs. Unfortunately, the Danesh-Noghrekar9 report does not clearly distinguish between field and predicted data. If it did, the case study would have been ideal to validate the model.

The data parameter range makes clear that the volumetric flow rate is predominantly gas; therefore, detailed consideration of the pipeline elevation profile was not deemed important for a steady-state flow.

On the basis of the Ilic studies,14 the classic Reynolds number, friction factor-type pressure drop correlation does not prove satisfactory.

Thus, using a single-phase approach, one can arrive at a simple relationship between pressure drop and Froude number (Equation 1 in accompanying box.)

Equation 1 can be expressed in a nondimensional form as Equations 2-4.

In other words, the nondimensional pressure gradient is proportional to the Froude number squared. Note that Equations 2 and 3 apply to single-phase flow; however, some elements of such behavior would be expected in certain types of multiphase flow using multiphase flow density and velocity in the equations.

A second order regression fit to the Kangan gas-condensate pipeline data resulted in Equation 5.

Results

Table 2 shows the results of pressure drop vs. several gas flow rates, predicted with the different correlations such as Lockhart and Martinelli,6 Eaton,7 Dukler,4 Beggs and Brill,1 and Mukherjee and Brill.12

Also, Table 3 gives the results of error percent and average percentage deviation for prediction of pressure drop if the above methods are used.

Note that these tables show good agreement between measurement data and calculated results (by the present model).

The simple, easy-to-use correlation presented here fits the Kangan gas-condensate field data, despite the vast differences in pipeline geometries and a disregard for elevation profiles and heat-transfer effects.

The author feels the application of the proposed correlation should be tested further with more field data.

References

- Beggs, H.D., and Brill, J.P., "A Study of Two-Phase Flow in Inclined Pipes," JPT, 255, pp. 607-17 (1973).

- Adewmi, M.A., and Bukacek, R.F., "Two-Phase Pressure Drop in Horizontal Pipelines," J. Pipelines, May 1985, pp. 1-14.

- Schweikert, L.E., "Tests prove two-phase efficiency for offshore pipeline," OGJ, Feb. 3, 1986, p. 39.

- Dukler, A.E., "Gas-Liquid Flow in Pipelines Research Results," American Gas Association, Project NX-28 (1969).

- Oranje, L., "Condensate behavior in gas pipelines is predictable," OGJ, July 2, 1973, p. 39.

- Lockhart, R.W., and Martinelli, R.C., "Proposed Correlation of Data for Isothermal Two-Phase, Two-Component Flow in Pipes," Chemical Eng. Progress, 45, 1, 39 (1949).

- Eaton, B.A., et al., "The Prediction of Flow Pattern, Liquid Holdup and Pressure Losses Occurring During Continuous Two-Phase Flow in Horizontal Pipelines," JPT, 240, pp. 815-28 (1967).

- Taitel, Y., and Dukler, A.E., "A Model for Predicting Flow Regime Transitions in Horizontal and Near Horizontal Gas-Liquid Flow," AIChE J., 22, 1, 47 (1976).

- Danesh, A., and Noghrehkar, G.R., "Hilly Country Gas-Condensate Pipelines," Report P-3062, Oil Service Co. of Iran, Abadan (1976).

- Osman, M.E., and Ei-Faky, S.A., "Design methods for two-phase pipe lines compared, evaluated," OGJ, Sept. 2, 1985, p. 57.

- Battara, V., Gentilini, M., and Giacchetta, G., "Condensate-line correlations for calculating holdup, friction compared to field data," OGJ, Dec. 30, 1985, p. 148.

- Mukherjee, H., and Brill, J.P., "Pressure drop correlations inclined two-phase flow," Journal of Energy Resources Technology, 107, pp. 549-54 (1985).

- Yazdankia, A.M., "Design of gas-condensate transmission pipelines," Bavar. J., 4, pp. 29-38, Emam Hossain University (1997).

- Ilic, V., "Two-phase pressure drop in an inclined pipe," proceedings, Ninth Australian Fluid Mechanics Conference, Auckland, pp. 196-99 (1986).

The author

Saeid Mokhatab is a research assistant, in the chemical engineering department of Tehran University. He has also served as a research consultant in the design and fabrication of mixed chemical reactors at Tehran University (2000-2001) and as a teaching assistant in the chemical engineering department (1998-2000). And he has worked as a process engineer in South Pars gas field development project (2001-present) and a research consultant for BIPC, Iran (2001). He holds a BSc (1998) in gas engineering from Tehran University and an MSc in chemical engineering (2000) from Tarbiat Modarres University, Iran.