Model accurately predicts intermediate casing-run surge pressure in Marlin SS-1 well

Significant casing-job planning and modeling, with a dynamic-surge model, enabled BP PLC successfully to run and cement the 135/8-in. intermediate casing, in the subsea development well Marlin SS-1, with the full or desired cement returns.

The company drilled the Viosca Knoll Block 915 well last year in 3,540 ft of water to 12,432-ft total depth with the semisubmersible drilling rig Noble Jim Thompson (Fig. 1).

The 135/8-in. intermediate casing string, currently set at 9,119 ft, cases off the 17-in. borehole. The integrity of this string is highly critical both in terms of zonal isolation and overall project life.

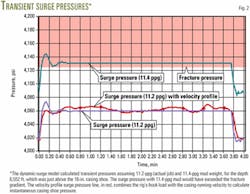

With information from the model, engineers fine-tuned the mud weight from 11.4 to 11.2 ppg to complete the job successfully and without fracturing the formation.

If the formation had fractured, the casing job would have required remedial cementing, which would have added significant cost to the project and resulted in reduced integrity for the 13 5/8-in. casing string.

Deepwater wells

Increased deepwater and ultradeep drilling operations have triggered the need to control wellbore pressures within a narrow window between pore pressure and fracture gradient.

Operators need to take precautions with regard to dominant surge pressures and counter-intuitive swab pressures while running casing.

The case study of the subsea well Marlin SS-1 clearly highlights the need to study and analyze wellbore pressures prior to and while running casing, especially when the window between pore pressure and fracture gradient is small.

Prejob design

Earlier on, during the design phase, the Marlin team had identified the limitations of using conventional steady-state surge models for the 135/8-in. casing run due to pore pressure and fracture gradient constraints.

The Marlin engineers decided to use the computer application based on an enhanced dynamic or transient surge-swab model, which Houston-based Landmark Graphics Corp. calls Wellplan, to study the implications of running the 13 5/8-in. casing.

This dynamic surge-swab model stems from the first model developed by Lubinski and modified over the years by various authors.1

Engineers performed a very significant amount of planning or frontend loading, using the surge model, to optimize running speeds and mud rheologies and to verify the surge-reduction tool estimations.

Drilling, cementing operations

During drilling of the 17-in. hole section, a pressure-while-drilling (PWD) tool monitored bottomhole pressure and supplied the equivalent-circulating density (ECD) data throughout the entire interval.

At 7,303 ft, crews increased the mud weight from 11 ppg to 11.2 ppg because of background gas increase.

Drilling continued to 7,867 ft where crews further increased the mud weight to 11.4 ppg because of background gas.

Drilling continued after increasing the mud weight. The hole began taking mud at 7,970 ft and continued through 8,000 ft, where a lost-circulation material (LCM) pill was spotted on bottom to control losses.

The hole experienced severe losses at 8,053 ft.

The simulation and design work that had been done earlier made an easier task of performing new sensitivity simulations quickly as the drilling parameters, primarily mud weight, changed.

This helped the Marlin engineers to make correct decisions with regards to ECD management at this critical conjunction.

Several case scenarios were run with different mud weights, which revealed that running the casing with 11.4-ppg mud in the hole was highly risky and might have caused formation fracturing and that 11.2 ppg would be the safest mud recommended for the operation (Fig. 2).

The rig spotted another LCM pill on bottom and pulled the drillstring to 6,641 ft to allow the LCM pill to soak. At the same time, crews displaced the 11.4-ppg mud in the hole to 11.3-ppg mud, which was eventually cut back to 11.2 ppg.

After lowering the mud weight to 11.2 ppg, the rig ran the drillstring back to bottom and continued drilling 9,144 ft with no losses.

Crews logged the well and ran the 13 5/8-in. casing to the bottom with full returns and subsequently cemented it without problems.

Fig. 2 shows the transient pressures with 11.2-ppg and 11.4-ppg mud weight at the depth 6,552 ft, which is just above the 16-in. casing shoe at 6,672 ft.

Hook-load confirmation

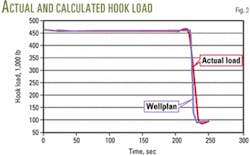

To verify the accuracy and yield confidence in the model's ability to predict surge pressure during casing operations, several post simulations were run with the hook load data available from the job.

In the absence of downhole pressure data for the casing run, an attempt was made to compare the hook load predicted by the model with the actual hook load collected during the casing running-in operations.

Fig. 3 shows hook load predicted using the transient model as well as the actual data.

The model predicted slightly higher hook load than the actual data, which was primarily due to the method of measuring hook load. The friction in the sheaves of the crown and traveling blocks influences the actual hook load response, which is not considered in the model.

Even with this limitation, the predicted hook load matched the actual data very closely.

Using the actual velocity profile of a casing joint running into the well, along with hook load, the authors calculated the corresponding transient pressure, which closely matched the simulated results, which is apparent from the surge pressure with velocity profile curve (Fig. 2).

The post-job results reinforce that the decision to reduce the mud weight to 11.2 ppg was the correct one.

The authors

Robello Samuel is a technical advisor with Landmark Graphics, Houston. At present, he is the technical and engineering lead for the well planning application suite. Samuel holds BS and MS degrees in mechanical engineering from the University of Madras, India. He also holds MS and PhD degrees in petroleum engineering from the University of Tulsa.

Faris Bajwa is an engineering consultant with Landmark Graphics Corp. and for the past 2 years has worked as an onsite consultant for BP's upstream technology group in Houston. He holds a BS in petroleum engineering from the University of Tulsa and an MS in environmental science from the University of Houston.

Mark Franklin is a senior drilling engineer with BP, currently working on deepwater Gulf of Mexico projects. He has 18 years of diverse experience, holding various operations positions in the US Rocky Mountains and working on drilling, completions, and production projects in Latin America. He is a registered professional engineer and holds a BS in petroleum engineering from the University of Southwestern Louisiana, Lafayette.

John LeBlanc is a senior drilling engineer with BP PLC and currently works with Gulf of Suez Petroleum Co., in Cairo, Egypt. He holds a BS in petroleum engineering from the University of Southwestern Louisiana, Lafayette.

Acknowledgments

The authors thank BP PLC and Landmark Graphics Corp. for permission to publish this article.

Reference

- Samuel, G.R., Sunthankar, A., McColpin, G., Bern, P., Flynn, T., "Field Validation of Transient Swab/ Surge Response with PWD Data," SPE Paper No. 67717, presented at the SPE-IADC Drilling Conference, Amsterdam, Feb. 27-Mar. 1, 2001.