Petroleum industry advances international standards

The petroleum industry has demonstrated support for international standardization by issuing in the past 3 years a stream of standards through the Geneva-based International Organization for Standardization (ISO), moving away from existing industry standards, national standards, and company specifications.

Charged with preparing standards for a wide selection of materials, equipment, and offshore structures for the petroleum, petrochemical, and natural gas industries,

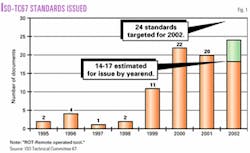

ISO Technical Committee 67 (ISO-TC67) has worked for issuance of 53 international standards during 1999-2001 (Fig. 1).

ISO-TC67's management and executive committees had planned for 24 additional international standards to be issued in 2002.

The 2002 prospective publication list has fluctuated from a high of 33 standards documents estimated in October 2001, settling to the lower estimate of 14-17 documents that the committee feels it can realistically publish by yearend (Fig. 1).

This is according to the ISO-TC67 publication-tracking list (www.tc67.net).

Many of these standards are based on familiar American Petroleum Institute (API) specifications and other relevant industry documents such as issued by National Association of Corrosion Engineers (NACE) and European Federation of Corrosion (EFC), as examples.1

The petroleum industry and national standardization organizations support international standards for worldwide applications.

American, European, and other standards bodies are adopting ISO and IEC (International Electrotechnical Commission) standards for regional use and even adopting back international standards that were written largely from the regional standards.

International standards

The ISO is a worldwide nongovernmental federation of national standards bodies from 140 countries, with one standard body representing each country.

Established in 1947, ISO's mission is to promote development of standardization and related activities in the world with a view to facilitating the international exchange of goods and services and to developing cooperation in the spheres of intellectual, scientific, technological, and economic activity.

ISO's work results in international agreements, which are published as International Standards.

According to the organization, "ISO" is not an acronym for the International Organization for Standardization but is derived from the Greek word "isos," meaning "equal," which is the root of the prefix "iso-" that occurs in a host of terms, such as "isometric."

Adopting the name ISO promotes the line of thinking from "equal" to "standard" and avoids the many acronyms that result from translating the organization's name into the many different national languages.

Rigs, equipment, and personnel for both land based and offshore operations move daily from one part of the world to another. The petroleum industry has growing interest in the use of international standards to enhance safety and environmental performance and to lower costs.2

The London based International Association of Oil & Gas Producers (OGP) highlights that international standards reduce costs and delivery time and facilitate trade across national borders. International standards also offer support for regulatory authorities to set goals and functional regulations, while achieving higher levels of safety through better design.1

The OGP has adopted an official position on international standardization through ISO and IEC, as follows1:

- The industry should promote development and use ISO and IEC international standards.

- International standards should be simple and fit for purpose.

- Industry and stakeholders should use international standards without modification wherever possible.

- Consensus of need should be the basis for the development of standards.

- Industry and stakeholders should avoid duplication of effort.

- Companies should minimize in-house specifications, where possible, and write them as functional requirements.

- "Users" should have representation on standards work groups.

OGP says that this approach to international standardization should minimize nontechnical barriers to trade, enable more efficient worldwide operations, and improve the technical integrity of equipment, materials, and offshore structures used by the petroleum and natural gas industries.

Developing standards

Getting an international standard issued is an extensive process.

International standards are documented agreements containing technical specifications or other precise criteria that stakeholders must use consistently as rules, guidelines, or definitions of characteristics, to ensure that materials, products, processes, and services are fit for their purpose.

An example is the ISO international standard-derived format of the credit cards, phone cards, and "smart" cards that have become commonplace. Adhering to the standard may define a feature such as a specific optimal 0.79-mm thickness that allows cards to be used worldwide.

According to ISO, an industry will develop international standards through consensus, taking into account the views and work of manufacturers, vendors, users, consumer groups, testing laboratories, governments, engineering professions, and research organizations.

An industry-wide effort would be expected to provide global solutions to satisfy industries and customers worldwide. International standards, being market driven, are based on voluntary involvement of all interested stakeholders in the marketplace.

ISO international standards development occurs in three main phases.

- An industry sector will express the need for a standard to a national ISO member body that will then propose a new work item to the ISO as a whole. Once it formally agrees with the need for an international standard, the ISO will assign the need to a technical committee, which will seek technical experts from interested countries to form working groups that will define the technical scope of the future standard.

- Once a working group has reached agreement on the technical aspects to be covered by the standard, the pro cess enters a second, consensus-building phase when technical experts representing countries negotiate the detailed specifications within the standard.

- The final phase consists of the formal approval with technical corrections and comments to the resulting draft international standard (DIS).

A final draft international standard (FDIS) serves as accuracy check but with no additional information included.

The DIS and FDIS acceptance criteria stipulate approval by two-thirds of the ISO members that have participated actively in the standards development process and approval by 75% of all members who vote, following which the agreed text is published as an ISO international standard (ISO).

Technological evolution, new methods and materials, and new quality and safety requirements are examples of factors that can render a standard out of date.

To take account of these factors, ISO has established the general rule that all ISO standards should be reviewed at intervals of no more than 5 years, with the standard revised, reaffirmed, or withdrawn during the review.

Active review, however, is usually sooner than five years. In many cases, work begins immediately upon publication of the ISO as the industry introduces newer technology.

ISO reports that its work has resulted in 12,000 international standards, representing more than 300,000 pages.

Technical Committee 67

ISO Technical Committee 67 involves more than 1,000 industry personnel working to convert as many as 138 national standards to ISO international standards, according to Cheryl Stark with BP PLC who chairs the committee.

The standards define the technical operations and limits for pipe (steel and aluminum), Pipeline transportation systems, drilling fluids, cements, hydraulic fluids, drilling and production equipment including drill stem, packers, and subsea production systems, oil-country tubular goods (OCTG), offshore piping, steam turbines, flexible couplings, compressors and turbines, and offshore structures including fixed steel or concrete, and floating systems.2

ISO-TC67 has divided its work into broad categories and assigned the work to seven subcommittees, which became six when Subcommittees 1 and 2 were combined into Subcommittee 2, as follows:

- Subcommittee 2 for pipeline transportation systems, which includes steel pipe for pipelines from the former Subcommittee 1.

- Subcommittee 3 for drilling and completion fluids and well cements.

- Subcommittee 4 for drilling and production equipment.

- Subcommittee 5 for casing, tubing, and drill pipe (OCTG).

- Subcommittee 6 for processing equipment and systems, including refinery and offshore topside equipment.

- Subcommittee 7 for offshore structures.

Each of these subcommittees may have several work groups further to divide topics into more manageable and narrowly defined areas of technical expertise.

In addition to the subcommittees, currently five, more narrowly defined working groups report directly to the technical committee (TC67), as follows:

- Working Group 2 for conformity assessment and certification principles.

- Working Group 4 for reliability and maintenance data collection.

- Working Group 5 for aluminum-alloy pipes.

- Working Group 7 for corrosion resistant materials.

- Working Group 9 for life-cycle costing.

Stark said, "In many cases, the work program of an [ISO-TC67] subcommittee is actually larger and more complicated than some other ISO technical committees handling other subjects."

ISO-TC67's work specifically excludes any standardization of ships, marine technology, or aspects of offshore structures covered by the International Maritime Organization (IMO) or governed by ISO Technical Committee 8.

ISO reestablished Technical Committee 67 in 1989 for the standardization of "materials, equipment, and offshore structures for the petroleum and natural gas industries." Within the past year, ISO's central secretariat added the petro chemical industry to ISO-TC67's scope.

The committee's advisory group initially reviewed available national standards issued by API and American National Standards Institute (ANSI).

In 1993-94, ISO-TC67 worked for issuance of 17 international standards, under a fast-track status, with only ISO facelifts to existing documents. These standards, however, have now fallen behind the 5-year review rule.

Chartered by ISO in 1947, a former technical committee for the same subject met during the period 1954-82 and had written 10 standards, which the newly formed committee had withdrawn due to obsolete technology.2

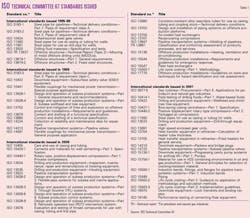

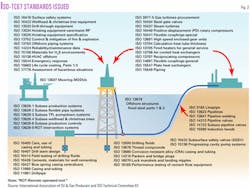

Table 1 lists, by year issued, the ISO-TC67 international standards published since 1995. Fig. 2 shows 57 ISO international standards grouped by intended use.

Many countries within the EU and Asia have accepted these standards into their national standards programs. Initial API readoption of ISO standards occurred in 2000.

Adoption of ISO standards

OGP reports that European countries are adopting most of the ISO-TC67 standards as their national standards, through the European Organization for Standardization (CEN), whose members are the national standards bodies in Europe.

CEN-TC12 has primary responsibility for setting standards of "materials, equipment, and offshore structures" for Europe and has chosen to allow ISO to be the lead organization.

CEN-TC12 administers the adoption of ISO-TC67 standards as European standards, designated EN ISO, and as a result, EC countries are obligated to withdraw national standards in favor of the EN ISO.

Currently CEN-TC12 has issued 34 EN ISO standards. National forewords may be added but technical provisions of the standards remain unchanged.3

The US API encourages cooperation between ISO subcommittees and work groups and corresponding API subcommittees says OGP.

API coordinators Mike Spanhel and Brad Bellinger commented that as ISO standards enter the stage of FDIS, the relevant API subcommittee could consider the standards for "adopt-back" as ISO-API standards.

The process eliminates duplication by replacing API recommended practices or specifications with ISO documents that were jointly developed and may address areas not covered by existing API documents, assuring close alignment between ISO and API standards.

The API subcommittees, which have balloting authority within API, decide which ISO FDIS to consider for adopt-back. API standards related to an ISO FDIS may be under consideration for revision on a different schedule from the ISO document, which underscores the need for close coordination between ISO and API standards developers.3

Bellinger and Spanhel and other sources had cited several examples of ISO international standards that have been adopted back by API, including:

- ISO 10423 as API 6A for wellhead and christmas tree equipment.

- ISO 10427-1 as API 10D for bow-spring casing centralizers.

- ISO 10432 as API 14A for subsurface safety valve equipment.

- ISO 10434 as API standard 600 for bolted-bonnet steel gate valves.

- ISO 11960 as API 5CT for casing and tubing.

- ISO 13534 as API RP 8B for hoisting equipment recommended practices.

- ISO 13535 as API 8C for hoisting equipment specifications.

- ISO 18165 as API 10F for cementing float equipment.

These standards are also listed in Table 1. Several other ISO-TC67 standards are under consideration for adopt-back by their corresponding API subcommittees.

API will label these documents jointly, as example, API 6A/ISO 10423. API will also append regional annexes to cover regulatory requirements or the API Monogram Program to the readopted standard.

Hydrogen sulfide service

In addition to being a killer gas, hydrogen sulfide causes severe cracking corrosion of the oil and gas industry's pipes and process equipment. The petroleum industry has cited the National Association of Corrosion Engineers (NACE) MR0175 to specify materials for "sour" service since 1975.

OGP reports that close cooperation between ISO, NACE, EFC, and CEN resulted in issuance of ISO 15156, the new standard for metallic materials in hydrogen sulfide-containing environments, giving the industry a common methodology for use worldwide in oil and natural gas production.

The ISO work group combined the latest version of NACE MR0175 and EFC publications No. 16 (1995) and No. 17 (1996) to create ISO 15156. To be issued in three parts, with ISO 15156-1 published in December 2001 and ISO 15156-2 and 3 expected for issue in the first-half 2003, the provisions are1:

- Part 1 gives general principles for selection of cracking-resistant materials and sets out rules that govern the use of the other parts of the standard.

- Part 2 will address cracking-resistant carbon and low alloy steels.

- Part 3 will address cracking-resistant corrosion resistant alloys and other alloys.

Parts 2 and 3 will address all forms of hydrogen sulfide-induced environmental cracking of metallic materials. Part 3 will adopt changes, now underway, regarding corrosion resistant alloys in NACE MR0175.

The entire ISO 15156 is on the work program for CEN to adopt the standard in Europe. NACE and ISO have reached an agreement in principle to govern the transition from NACE MR0175 to ISO 15156, including a maintenance panel to manage ongoing enquiries and interpretations of the standard.1

Wellhead equipment

ISO-TC67 published the second edition of ISO 10423 in August 2001. API has balloted and approved the international standard for adoption as the 18th edition of API Specification 6A for wellhead and christmas tree equipment.

API coordinator Brad Ballinger said he had seen the first paper copy of API 6A, 18th edition, hot off the press, at the June API Summer Standardization Conference on Oilfield Equipment and Materials in Denver.

The main text of this latest API 6A is identical to the ISO standard but adds an annex dealing with the API's monogram program.1

Additions to the new standard from the 17th edition of API Specification 6A include valve removal plugs, bull plugs, and back-pressure valves. The new standard is to carry both API and ISO logos.

Casing and tubing standards

ISO-TC67 issued the second edition of ISO 11960, the international standard for well casing and tubing, in October 2001.

Revised in conjunction with the base document and adopted as API 5CT 7th edition specification for casing and tubing, the standard includes dual units with tables in either SI or US customary units included as annexes.

ISO 11960 and API 5CT, to be issued with October 2002 as the effective date, will have identical main text and with both ISO and API logos on the cover.1

In addition to numerous small technical changes to the standard is addition of the term "casing and tubing accessory," which is a "one-piece tubular section used in a pipe string to provide mechanical and pressure integrity within the pipe string and facilitate the performance of some other function required of that pipe string."1

The change allows users more easily and clearly to specify to manufacturers that the requirements for the casing and tubing must be compatible with the accessories being purchased.

Subsea standards

OGP highlighted that close cooperation between API and ISO groups responsible for standards on subsea production equipment should yield a number of ISO subsea standards adopted as the next editions of the equivalent API standards.1

Work is ongoing to revise a number of published subsea standards, such as API 17A (ISO 13628-1) and API 17D (ISO 13628-4), for subsea production and wellhead equipment.

New work items are under development to address advances in the rapidly evolving subsea production field, such as getting API RP 17B for flexible pipe and API Specification 17K for bonded-flexible pipe into the ISO arena. A joint working group is developing ISO 16389 for dynamic risers.

Challenges

Table 2 gives a 2002 target list of standards that ISO-TC67 management and executive committees thought could have been published by yearend. Subcommittee and work group members continue work on a broad list of ISO international standards that are not shown on the list and have a target publication or issuance date of 2003 and beyond.

Stark highlighted that resources remain the biggest challenge for the technical committee and represent, basically, a "people" challenge.

The process requires maintaining a proper balance of operators, manufacturers, and government, but as a result of the current industry philosophy of merger, "right sizing," and early retirement, the pool of technical experts is shrinking.

Stark said that although most committees have adequate resources, this may not always be the case, however. The effort requires new or replacement experts to be trained and brought to a level of comfort within the ISO process. "We're always asking for volunteers," she said.

References

- "International Standards Bulletin," International Association of Oil & Gas Producers, London, No. 3, 2002.

- Stark, C.L., Heimer, J.A., Loppinet, A.L., Johansen, A.R., Reeve, P.T.N., Thomas, G.A.N., and Smith, D., "An Industry in Transition," Paper No. OTC 13295, presented at the Offshore Technology Conference, Houston, Apr. 30-May 3, 2001.

- "International Standards Bulletin," International Association of Oil & Gas Producers, London, No. 2, 2001.