Field use proves program for managing internal corrosion in wet-gas systems

A program for successfully managing internal corrosion in wet-gas gathering facilities has been proven in two major offshore gathering systems over the last 12 years. The two gathering systems were part of ANR Pipeline Co. before its merger, with Coastal Corp., into El Paso Corp.

This corrosion-management program and its supporting analytical techniques have improved the operational integrity of both gathering systems and yielded significant corrosion-mitigation cost savings. The savings were realized through reductions in treatment chemical expenditures, reductions in pipeline leaks, and improvement in the overall reliability of several segments of the pipeline systems.

The techniques described here give pipeline operators the ability to differentiate among internal corrosion initiation mechanisms at their earliest stages and thereby determine the most appropriate mitigative measures for corrosion control. In addition, these techniques have been used to evaluate the effectiveness of mitigation measures and for optimizing treatment protocols.

Problem

Many natural gas gathering systems must transport both liquids and gas, whereas by design gas transmission systems transport only dry natural gas. Often, the liquids transported in gathering pipelines consist of hydrocarbons and produced water and contain a variety of such undesirable constituents as bacteria, chlorides, sulfides, and others.

Most gathering systems have a large number of input sources (wells), are constructed of a wide variety of pipe diameters and materials, and are largely inaccessible to cleaning and inspection pigs. Monitoring for corrosion in offshore gathering systems is further complicated by the pipe being unreachable for direct inspection, except at great cost.

Finding, identifying, and controlling internal corrosion in these "wet" gathering systems can be a daunting task for pipeline operators and engineers.

Traditional efforts

Efforts to control internal corrosion in gathering systems have typically fallen into one of two categories:

1. Treating the entire system with corrosion inhibitor or biocide, and monitoring for residual levels.

2. Monitoring gas and liquid compositions and attempting to base the chemical treatment program on those data.

Under certain circumstances, these two methods may be the only options available to an operator. Neither, however, provides a thorough understanding of what is happening inside the gathering system nor offers the desired degree of confidence that mitigation efforts are actually effective. Further, both approaches have been known to yield inconsistent success in controlling internal corrosion.

The first approach, maintaining "prescribed" residual levels of treatment chemicals throughout the gathering system, is in a sense, a high cost form of "corrosion insurance." When some of the 1970s vintage offshore gathering systems in the Gulf of Mexico began to develop corrosion leaks in the mid-1980s, the use of broadly applied inhibitor programs escalated.

Typically, inhibition chemicals (and later, biocides) were injected continuously into the pipelines at wellheads, separators, or other points of liquid entry or transfer. Effectiveness of the program was determined by monitoring the "recommended" residual levels of treatment chemicals at downstream locations. Unfortunately, this approach did not consistently result in leak-free pipelines.

Problems occurred in getting the right type of chemical to the point where corrosion was actually occurring. The low flow rates in some laterals, stratified flow regimes, and presence of deposits covering some active internal corrosion sites resulted in the continuance of internal corrosion leaks for some operators.

Further, without a clear understanding of what was actually causing the corrosion in the gathering system, it was difficult to select and correctly apply a mitigation strategy that was effective.

The second traditional method of internal corrosion control in wet gathering systems, and one that evolved from earlier industry efforts, was to target chemical treatments based on gas and liquid compositional data. This was definitely a step in the right direction because operators were now attempting to understand better why corrosion was occurring in their facilities.

But significant limitations were also found with this approach.

One of the key problems is attempting to correlate bulk fluid composition data with localized surface activity in a pipeline. Low iron levels in aqueous samples, for example, are often hailed as key indicators of the success of a chemical treatment program. If a pipeline is plagued with highly localized attack (isolated pitting) or under deposit pitting, low iron levels in the bulk fluid would not be unusual.

Conversely, if a pipeline is transporting an aggressive liquid, perhaps with a low pH, then iron counts could provide useful information. Further, if the iron levels of the "source liquids" (at the point of origin of the liquids) are unknown, further uncertainty is added to the value of the liquid composition data.

Finally, analytical data from samples of co-mingled fluids obtained near the end of trunk lines and other such locations must be interpreted with great caution. Such samples can only be considered a "snapshot" of what is happening at that particular time, as inputs and operating conditions can change by the hour.

It is nearly impossible to determine what is happening in a given lateral line, based on the analysis of a co-mingled fluid from many sources. The same lines of thought apply to gas analysis data, bacteria testing, and analysis of solids from pigging or cleaning operations.

Thus, basing a corrosion-control program on compositional or microbial data becomes a complex undertaking, with many uncertainties.

The bottom line in corrosion control is achieved when corrosion engineers can understand what is happening to the internal surfaces of their pipelines. Admittedly, this is not easily attainable, particularly when direct observation of the internal surfaces of a gathering system is not practical.

For decades, pipeline operators have used traditional weight-loss coupons to approximate what is happening to the internal surfaces of their facilities. Weight-loss coupons, as commonly employed by industry, are also subject to limitations in the value of data they can provide and must be considered in terms of their statistical significance.

For example, isolated pitting corrosion could easily go undetected by traditional weight-loss coupons. Placement of coupons in locations that would provide relevant information can be difficult and costly. Yet, the value of having a steel surface that can be removed and directly examined after being exposed to the pipeline environment is still significant.

Over the last 12 years, the authors developed a monitoring and mitigation program that has overcome many of these challenges. This program combines some of the previous monitoring strategies with a new type of corrosion coupon, termed an "EM coupon" (coined from the use of electron microscopy in the coupon analysis).

Solution

A three-part program was developed to manage all internal corrosion mitigation and monitoring activities in two major offshore gathering systems. The key elements of the program consisted of:

- A data-management system that would link all key corrosion data to geographic locations on the pipelines.

- Protocols for collection and analysis of liquid, solid, and gas in the system.

- EM coupon technology.

Since a variety of GIS software exists today and many companies have either instituted an off-the-shelf system or developed their own, this part of the program will not be discussed here. It is enough to say that whatever data-management system is used must be flexible, robust, and able to sort and report data in a wide variety of ways.

Liquid, gas, and solid analysis data were used in several ways:

- For screening and prioritizing sites to receive coupon monitoring.

- For monitoring changes that occurred over the long term that could affect monitoring frequency or mitigation methods.

- For selecting the optimum type of treatment, if mitigation were needed.

Screening and prioritizing were accomplished by establishing a baseline of data for each gathering system to be evaluated. Typical liquid analysis would consist of quantifying cations, anions, pH, sulfides, carbonates, hardness, total dissolved solids, viable bacteria levels, etc.

Based on these baseline data, key operating factors, and the history of the line in question, recommendations for EM coupon monitoring and evaluation were made. Once coupon evaluations of a system were completed, liquid composition analysis would be performed on a reduced frequency to monitor for long-term changes in the system.

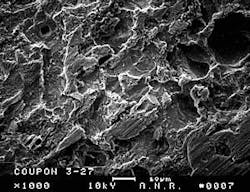

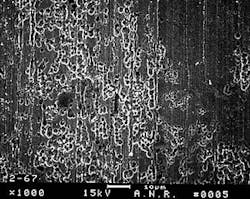

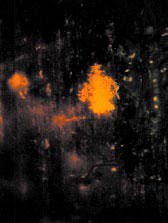

The key to our approach in controlling corrosion in wet gathering systems is EM coupon technology. Although the coupons themselves are of relatively simple design (Fig. 1), EM coupons offer an analytical approach that can discriminate among various forms of corrosion initiation.

Subjected to a combination of analytical techniques, steel test coupons for electron microscopy can provide information about the surface microbiology and internal corrosion of the systems monitored.

Optical microscopy, scanning electron microscopy (SEM), and epifluorescence microscopy are employed in the coupon analysis protocol. Special preparation techniques were also utilized to maximize the data obtained from the coupons. Relationships between physical-microbiological surface conditions and corrosion initiation events have been observed over a 12-year period in which these combined methodologies were used.

In evaluation of various factors that can contribute to the internal corrosion of pipelines, the utility of monitoring sessile microbial populations has become well established in many industries. Early work by Costerton1 2 and field studies by others3 have shown that sessile biofilms can initiate and facilitate corrosion4 and that there is an inconsistent relationship between planktonic bacteria levels and microbiologically influenced corrosion5 (MIC).

Additionally, diagnosis of MIC by direct examination of advanced internal corrosion is usually of dubious value. Our experience in long-term monitoring of viable bacteria levels and examining actual corrosion in wet-gas gathering systems has corroborated these findings.

Developing sensitive methods for detecting MIC initiation has been a continuing problem.6 Distinguishing MIC from pitting corrosion related to metal structural characteristics5 is complicated by the fact that high numbers of microbes do not always correlate with corrosion frequency.7

Little8 has demonstrated that bacteria later can colonize corrosion nodules that were initiated by other causes. Thus, as we tried to develop ways to detect the initiation of MIC in a natural gas gathering system, we focused on monitoring for the presence of sessile or biofilm-forming bacteria.

A histological embedding method described by Aldrich9 was adapted for routine analysis of biofilms obtained from actual field conditions and combined with optical and electron microscopic analyses of test coupon surfaces.

In this procedure, steel monitoring coupons, along the biofilms attached to them, were embedded in plastic. The plastic embedment preserved the bacteria in the biofilm for examination with an optical microscope, while the coupon itself could then be examined in the scanning electron microscope for evidence of pits corresponding to the bacteria observed in the adjacent plastic.

The EM coupons were exposed in situ to produced liquids handled by the pipeline system. Results from coupons exposed to field conditions were compared with results from coupons exposed under controlled microbial culture conditions in the laboratory.

Observations of biofilms and their resultant corrosion-initiation features on field and laboratory exposed- steel surfaces demonstrated consistent micro-morphological characteristics that could be used to identify biotic pit initiation and distinguish between various forms of corrosive attack (Figs. 2, 3, and 4).

Certainly, initiation is only one step in a lengthy and complex process that can lead to severe corrosion. If we are in fact observing the fixation of microscopic anodic sites that continue to propagate in the given local environment, however, this finding then becomes quite significant from an operations viewpoint.

Even in light of the statistical limitations inherent in coupon testing, the detection of biotic pit initiation at an early stage and after relatively short exposure periods can be useful to pipeline operators, particularly in terms of monitoring the effectiveness of biocides and inhibitors.

A summary of our key findings over the last 12 years, as related to the use of EM coupons for monitoring corrosion in wet gas gathering systems, is as follows:

- One-to-one relationships between the physical characteristics of biofilms and resulting corrosion-initiation sites on coupons made of pipeline steels were observed in both laboratory and field tests.

- Relationships between bacterial colonization and pitting on a microscopic scale were observed for exposures of less than 8 hr in the laboratory. Results from EM coupons exposed to field conditions showed a similar tendency, but optimum exposure times for observation of the one-to-one relationship varied widely depending on the pipeline environment.

- A distinct corrosion pattern indicative of biotic pit initiation in the laboratory and field environments evaluated was observable through the use of scanning electron microscopy in combination with the unique preservation and analysis procedures employed. This corrosion pattern was not observed in sterile control tests.

- Other types of corrosion initiation events were also resolvable with this combination of technologies, including under-deposit attack, corrosion-erosion, uniform etching, and even pitting attributable to certain treatment chemicals.

Applications

Once equipped with a systematic process for internal corrosion management and a tool that could distinguish between corrosion initiation mechanisms inside the pipe, we proceeded to apply these tools to two large offshore gathering systems.

The approach consisted of three phases: prioritization, evaluation, and monitoring.

In prioritization, we reviewed the operating history, flow conditions, liquid and gas compositions, and current corrosion monitoring-treatment programs used in the gathering system. The prioritization phase was essentially an internal-corrosion risk assessment. This phase allowed us to target and implement the second phase where it would have the greatest benefit.

Evaluation helped provide a comprehensive picture of the operational, chemical, and microbial conditions in a certain segment of the gathering system. In this phase, we performed comprehensive analysis of all inputs to the system and monitored key locations using EM coupons at least twice to verify whether corrosive conditions existed.

Once the type of internal corrosion initiation was known, a mitigation strategy could be developed.

Armed with a wealth of information from the comprehensive evaluation and plans for mitigation, we then proceeded to the monitoring phase. Where appropriate, mitigation steps were implemented, monitored (using EM coupons) for effectiveness, and adjusted where necessary.

Once mitigation was shown to be effective, the frequency of EM coupon monitoring was moved to a 6-month schedule. Further, the need for regular ongoing liquid and bacteria monitoring at those sites no longer existed.

Costs, benefits

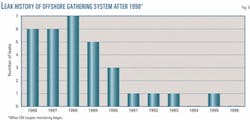

This program has proven highly successful in controlling internal corrosion and the costs associated with managing it. Cost containment has been achieved primarily through reducing leaks (their associated repair and related costs) and by reducing inhibitor and biocide applications.

Fig. 5 shows examples of the reduced leak rates for one of the offshore gathering systems in which this program was implemented.

Without a means directly to determine whether internal corrosion is occurring, inhibitor and biocide treatment must be based on such indirect evidence as chemical composition data or bacteria analysis.

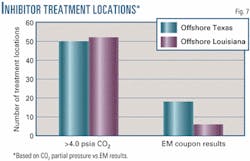

Once we used EM coupon data as the primary determination of whether mitigation was required, the costs of our mitigation program greatly declined, while corrosion control was even more effective than before. Figs. 6 and 7 show how both biocide and inhibitor applications were reduced in the two gathering systems where we implemented EM coupon technology.

In the years that followed implementation, leak rates in both systems remained low. Since ANR Pipeline merged with El Paso in 2000, this technology is now being integrated throughout El Paso's pipeline systems.

To be certain, there are also costs associated with conducting an internal-corrosion monitoring program of this nature. Analytical and logistical support for EM coupon monitoring is considerably more expensive than for conventional weight-loss coupons. The benefits have been proven to far outweigh any additional costs, however.

Currently, no third-party laboratories offer coupon analysis such as this, nor do they have the experience properly to interpret the corrosion morphologies. In a forthcoming article, the authors will present detailed laboratory procedures for EM coupon analysis so that others can develop experience with these methods.

Acknowledgments

The authors offer their appreciation to Henry Aldrich of the University of Florida for his contributions in developing the EM coupon analysis techniques and long-term guidance of our efforts. We also thank ANR Pipeline Co. and El Paso Corp. for its support of our work and permission to publish our findings. Finally, we acknowledge Chris Edwards at the University of Michigan for his valued contributions to this technology.

References

- Costerton, J.W., and Geesey, G.G., "The Microbial Ecology of Surface Colonization and of Consequent Corrosion," Biologically Induced Corrosion, S.C. Dexter, ed.; Houston: NACE, 1986.

- Costerton, J.W., Geesey, G.G., and Jones, P.A., "Bacterial Biofilms in Relation to Internal Corrosion Monitoring and Biocide Strategies", MP, Vol. 27, No. 4 (1988), pp. 49-53.

- Angostini, R.A., and Young, R.D., "A Case History: Investigations of Microbially Influenced Corrosion in a West Texas Waterflood," presented to CORROSION/90, Houston, Apr. 23, 1990.

- Lee, W., and Characklis, W.G., "Corrosion of Mild Steel Under Anaerobic Biofilm," Corrosion, Vol. 49, No. 3 (1993), pp. 186-199.

- Little, B., and Wagner, P., "Myths Related to Microbiologically Influenced Corrosion," MP, Vol. 36, No. 6 (1997), pp. 40-44.

- Stoecker, J.G., II, "Microbiological and Electrochemical Types of Corrosion: Back to Basics," MP, Vol. 34, No. 5 (1995), pp. 49-52.

- Little, B.J., Ray, R.I., and Wagner, P.A., "Tame Microbiologically Influenced Corrosion," Chem. Eng. Prog., Vol. 94, No. 9 (1998), pp 51-60.

- Little, B.J., Wagner, P.A., Hart, K.R., and Ray, R.I., "Spatial Relationships between Bacteria and Localized Corrosion," presented to CORROSION/96, Houston, Mar. 25-29, 1996.

- Aldrich, H.C., Choate, A., McDowell, L., Bono, P., Chynoweth, D., Pope, D., and Yang, J., "Microscopy of Microbial Corrosion of Pipeline Steel in a Model System," in Microbially Influenced Corrosion and Biodeterioration, N.J. Dowling, M.W. Mittelman, J.C. Danko, eds., Knoxville, Tenn.: Univ. of Tennessee Press, 1991, pp. 5/57-64.

The authors

Richard B. Eckert (r.eckert@ att.net) joined Kiefner and Associates Inc. after a 19-year career with ANR Pipeline Co. and El Paso Energy Corp. His expertise includes pipeline failure investigation, product evaluation, system integrity issues, nondestructive testing, pipeline welding, and quality assurance. Eckert served as technical advisor to the GRI MIC Committee 1989-98. He holds a BS in metallurgical engineering from Western Michigan University.

Bruce A. Cookingham (Bruce. [email protected]) is an internal corrosion consultant for El Paso Corp. He has more than 23 years of corrosion related experience with operating, designing, and managing of gas pipelines in gathering and storage field systems. He has contributed on several NACE recommended practice standards, served as committee member on the GRI Microbiological Influenced Corrosion Program, Pipeline Research Committee International (PRCI) corrosion supervisory committees, and is currently serving as ad hoc chair on several PRCI corrosion supervisory committees, PRCI internal corrosion emphasis chair, NACE chairman of Task Group 038 on Control of Internal Corrosion in Steel Pipelines and Piping Systems, industry lead for the Interstate Natural Gas Association of America on internal corrosion direct assessment.