North Sea giant gas field approaches final months

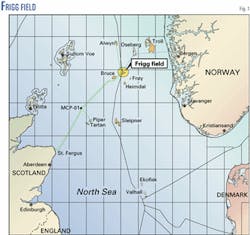

The end is fast approaching for Frigg, a giant natural gas field with associated condensate that straddles the median line between the Norwegian and UK sectors of the North Sea, with facilities both in Norwegian Block 25/1 and UK Block 10/1 (Fig. 1).

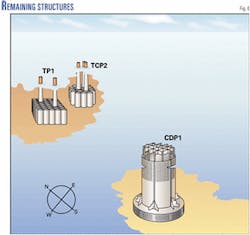

The field's three concrete substructures represent a complex challenge for the decommissioning process.

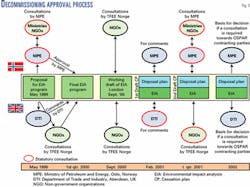

According to the operator's cessation plan, Frigg may cease production as early as 2003, with the abandonment and decommissioning process lasting another 8 years (Fig. 2).

Both governments of Norway and the UK will need to approve the disposal plan in their respective sectors. But during the decommissioning phase, operator TotalFinaElf Exploration Norge AS intends to treat the field, as far as possible, as one unit, even though both the UK and Norway have slightly different legislation schemes for disposing of offshore facilities.

The regulating agency in Norway is the Ministry of Petroleum and Energy (MPE), in Oslo, and in the UK it is the Department of Trade and Industry (DTI), Aberdeen.

In addition, the facility disposal will comply with the Oslo-Paris (OSPAR) Convention and International Maritime Organization (IMO) guidelines.

The OSPAR accord, passed in 1998, requires removal of all redundant offshore oil and gas platforms weighing more than 10,000 tonnes in the northeast Atlantic area, which includes the North Sea. This accord applies only to platforms made of steel.

Following the merger of the TotalFina Group and the Elf Group in 2000, the current Frigg licensees are:

- TotalFinaElf Exploration Norge AS (operator) 16.068%.

- Norsk Hydro Produksjon as, 19.992%. TOTAL Norge AS, 12.596% (managed by TotalFinaElf Exploration Norge AS).

- Statoil ASA, 12.164%.

- Elf Exploration UK PLC, 26.120% (managed by TotalFinaElf Exploration UK PLC).

- TotalFinaElf Exploration UK PLC, 13.060%.

The cessation plan, in 2001 money, estimates the disposal cost for the Frigg field will be 3,415 million kroner ($434 million). A 1,030 million kroner ($131 million) additional cost will be spent on plugging and abandoning the wells and taking out of service the topsides equipment.

Proposed plan

The Frigg Treaty between Norway and the UK governed the development of Frigg. The treaty designated Elf Norge in Stavanger as operator of Frigg while Total Oil Marine in Aberdeen was designated as operator of both 32-in. UK and Norwegian gas export pip elines from Frigg to St. Fergus in Scotland.

The treaty did not address provisions for eventual disposal of the platforms, seabed pipelines, cables, or drill cuttings.

The decommissioning consultation and approval process for Frigg started in May 1999, and TFEE Norge expects final approval of the plan towards year end 2002 (Fig. 3). The second draft of the cessation plan submitted in November 2001 contains a disposal part and an environmental impact assessment part.

TFEE Norge has held seminars and workshops with nongovernment organizations, such as various experts and environment groups to review the studies and ensure that both the input data and the conclusions were valid.

It says planning for decommissioning is a lengthy and far-reaching process, and it has made efforts to ensure that an open and transparent dialogue takes place with all stakeholders, including nongovernment organizations, throughout the process.

The current status of the plan is that the comment period for the second draft has concluded and TFEE Norge has started preparing a new document for OSPAR that it expects to complete in late summer 2002. This document will only involve the concrete platforms, and OSPAR will have a comment period of up to 16 weeks.

After this comment period, TFEE Norge says that the MPE will send the Norwegian parliament a white paper for its approval. A similar procedure will also occur at the same time in the UK.

Frigg

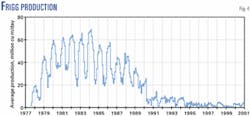

The cessation plan estimates that Frigg will have produced 6.7 bcf of gas and 6.2 million bbl of condensate when it stops producing in 2003. This represents a recovery of about 77% of initial gas in place. The producing reservoir has a strong aquifer drive. Fig. 4 shows the production history.

Initially the field produced from 47 wells drilled from 1976 to 1979. The field also had one observation well that was later converted to an oily water disposal well.

A redevelopment in 1989-90 involved abandoning all wells on Platform CDP1 and drilling two deviated wells from Platform DP2

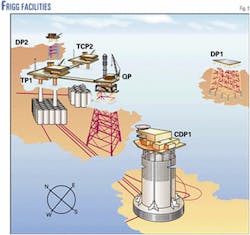

Frigg has five operating fixed platforms: three (TP1, QP, and CDP1) in the UK sector and two (TCP2 and DP2) in the Norwegian sector (Fig. 5). In addition, the field has one steel substructure (DP1) in the Norwegian sector that was damaged and sank during installation in October 1974.

Platform installation occurred between 1974 and 1977. Three platforms, TCP2, CDP1, and TP1, have concrete gravity-base substructures. DP2 and QP are tubular steel jacket-type substructures. Weights and dimensions of the six platforms are:

•Treatment and Compression Platform 2 (TCP2), 85 m by 65 m, 22,882-tonne topsides, and a 116 m by 116 m by 129-m high, 231,179-tonne (including ballast) concrete substructure. The platform is in operation as an oil and gas treatment facility and for generating electricity.

•Treatment Platform 1 (TP1), 90 m by 44 m, 7,840-tonne topsides, and a 72 m by 72 m by 126-m high, 163,179-tonne (including solid ballast) substructure. The platform is in operation as a riser platform connecting the Alwyn pipeline to Frigg UK Pipeline (PL 7).

•Quarters Platform (QP), 35 m by 30 m, 3,639-tonne topsides, and a 54 m by 54 m by 113 m-high, 4,757-tonne (including piles) steel structure. The platform serves as a living quarters and the field's control center.

•Concrete Drilling Platform 1 (CDP1), 64 m by 63 m, 4,840-tonne topsides, and a 101 m by 101 m by 107-m high, 418,611-tonne (including solid ballast) concrete substructure. The wells on this platform have been plugged and abandoned and the processing facilities have been partially decommissioned.

•Drilling Platform 2 (DP2), 61 m by 35 m, 5,479-tonne topsides, and a 62 m by 44 m by 106 m-high, 9,797-tonne (including piles) steel substructure. The platform is in operation as a production platform.

•Drilling Platform 1 (DP1), 62 m by 44 m by 106-m high, 7,300-tonne steel structure that sank during installation.

The cessation plan says that no oil has been stored in any of the platform substructures.

The infield pipelines and cables to be decommissioned are between DP2 and TCP2, CDP1 and TP1/QP, and TP1. A flare platform tower was removed in 1996 and its base in 2001.

Three of the platforms, TP1, QP, and TCP2, are bridge-linked and form the Frigg central complex.

Besides processing and exporting the hydrocarbons from Frigg, the facilities on TCP2 were modified to handle production from North East Frigg, East Frigg, Lille-Frigg, Odin, and Fr y. TFEE Norge operated all of these fields except Odin, which was operated by Esso Norge AS.

Gas from these fields went to St. Fergus through the Frigg Norwegian pipeline, while produced liquids, since 1995, went to Sture in Norway via the Frostpipe and Oseberg Transportation System

Production from all satellite fields tied into TCP2 has now ceased.

Cessation plan

After Frigg gas production stops, the cessation plan calls for a continuous offshore preparatory activity until the end of 2005. This will be followed by offshore removal work mainly during the summer months. It expects onshore disposal activities to be continuous from 2006, with the program being completed in 2011.

The main recommendation in the cessation plan calls for leaving the concrete substructures in place and removing everything else (Fig. 6). The evaluation based its conclusion after considering the health and working environment, safety, environmental aspects, and cost of other options.

The cessation plan does not seek to abandon the export pipelines (Frigg Transportation System) from Frigg to St. Fergus or the pipelines between Frigg and other fields. These pipelines will continue carrying gas from these other fields to the UK.

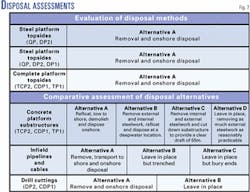

Fig. 7 shows the evaluations and comparative assessments conducted for decommissioning the Frigg field facilities. The plan says that as much as practicable all equipment and materials removed from the platform will be reused or recycled.

It recommends that steel components of the topsides of the concrete platform should be removed and taken ashore for disposal, and that the concrete substructure, including the concrete deck beams, should be suitably marked and left in place.

If left in place, the estimate is that the three concrete substructures in the next 100 years will show very little physical damage. After that time, corrosion of the horizontal reinforcement in the splash zone is likely to give rise, initially to spalling of the concrete, and later to local damage. The study predicts that the TCP2 and TP1 columns, and the CDP1 walls will remain in place for 500-800 years before collapsing.

Other recommendations in the plan are to:

- Remove all in-field pipelines and cables between the Frigg installations and bring them to shore for disposal.

- Leave the drill cuttings in place on the seabed and within the walls of one concrete substructure. It indicates that a small amount of drill cuttings are on the seabed around DP2, with a maximum thickness of 20 cm. Drill cuttings from the wells on CDP1 are contained within the concrete walls of the substructure.

Currently gas from the North Alwyn field is routed, via TP1, into the Frigg UK Pipeline (PL 7) to St. Fergus. The cessation plan says that this gas will be rerouted through a direct subsea connection between the North Alwyn pipeline and the Frigg UK Pipeline (PL 7), scheduled for completion in 2003.

Vesterled pipeline, installed in 2001, links the Norwegian gas network through the Heimdal field and the Frigg Norwegian Association (FNA) pipeline. It also carries UK Galley field gas to St. Fergus.

Options discarded

The cessation plan also looked at other options for the facilities but found none that was attractive.

At present, it says even after making significant exploration investments nearby, the Frigg owners found no hydrocarbon reservoirs in the area that can be economically developed from Frigg.

Also the plan looked at the possibility of using the Frigg facilities as an export center but rejected this option because technology today allows direct subsea tie-in of pipelines to the Frigg export pipelines without needing a platform. It also found the use of Frigg facilities as a processing center not to be viable.

The study also rejected the use of the facilities for a number of non oil and gas applications, such as artificial reefs; wind-generators; or emission-free, gas-fired power plants. It found that these options technically are uncertain and judged them be uneconomic.

The study found little reuse potential for the facilities. It found no potential reuse application for the three steel substructures at another location. It did determine that the concrete substructures have a reuse potential at other locations, but it did not recommend this possibility because of undue technical risk and risk to personnel in moving these concrete structures.

Because of their age, the study found little reuse potential for the topsides equipment, although it said work will continue in pursuing this possibility.

The study indicated that because society generally considers dumping structures in deep water undesirable, the steel structures should be brought ashore for disposal. The option of cutting the structure to -55 m to allow free passage of vessels was rejected because of the technology and cost for cutting have not been fully proven. And cutting to this depth would still interfere with fishing activity.