Conoco successfully uses team approach for FCC revamp

Based on a presentation to the NPRA Annual Meeting, Mar. 17-19, 2002, San Antonio.

Conoco Inc. successfully implemented a major, innovative project to address catalyst circulation and improve yields from an FCC unit at its Lake Charles, La., refinery. A key component was adding an external spent-catalyst stripper to reduce the load on the existing internal stripper.

Conoco also replaced the regenerated catalyst plug valve and regenerated catalyst J-bend standpipe with a cold-wall wye section and UOP LLC's elevated Optimix feed distribution system. The project improved FCC catalyst circulation, resulted in increased conversion, and improved yield selectivity while providing flexibility to process heavy aromatic feedstocks.

The project's success can be attributed to advance planning and to the team approach taken by Conoco, International Alliance Group (IAG), Andrews FCC Consulting, and UOP.

About 2 1/2 years before the shutdown, Conoco assembled a team of FCC specialists to discuss operational and reliability objectives. They applied knowledge learned from previous FCC projects executed at Conoco's Ponca City and Denver refineries and overcame a significant catalyst circulation challenge inherent in Orthoflow-style FCC units. The early planning effort allowed time to evaluate technical solutions and define the project scope to deliver innovative FCC unit revamp solutions.

IAG provided single-point responsibility for meeting project goals through turnkey implementation of technology, engineering, procurement, and construction. The team approach resulted in a successful revamp and also allowed Conoco to improve FCC operations and unit profitability before the turnaround.

Background

The Lake Charles refinery, Westlake, La., is Conoco's largest facility, with a crude distillation capacity of 245,000 b/d. The refinery processes heavy, high-sulfur crude and low-sulfur crude. It produces a full range of fuel products and a feedstock for Excel Paralube, Conoco's joint venture facility that produces high-quality lubricating hydrocracker base oils.

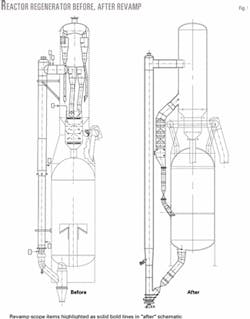

The FCC converter is a Kellogg Orthoflow F design (Fig. 1), which started up in 1979 replacing an older TCC unit. Original unit capacity was 30,600 b/d of gas oil feed.

The unit has been debottlenecked over the years; the last major project was completed in 1993, in which Conoco increased unit feed capacity to 48,000 b/d. The 1993 modifications included a new riser and feed nozzles, changes to the disengager cyclones, and extensive changes to the fractionator and gas plant.

Recent operation

The FCC typically processes a gas oil feed mixture of approximately 75% hydrotreated coker and vacuum gas oils, and 25% sweet virgin gas oils.

Existing operating constraints included:

- Air blower capacity.

- Wet-gas compressor motor amps.

- Catalyst circulation instability in the spent-catalyst standpipe.

- High flue-gas afterburn in the flue-gas line to expander (maldistribution).

Generally, the FCC operates with a high riser outlet temperature. The feed preheat temperature is set high to minimize coke yield and maximize feed rates within the air blower capacity. Conoco operates the regenerator in full burn.

The Lake Charles FCC converter configuration is typical of the stacked Orthoflow F design. Eight elevated radial-feed nozzles in an external vertical riser introduce the feed. The riser termination consists of four rough-cut cyclones and five secondary cyclones. The catalyst stripper, which is internal to the disengager vessel, uses two stages of stripping steam distribution and is heavily loaded.

The stripper terminates into a long vertical spent-catalyst standpipe that connects the stripper, internally through the regenerator vessel, to a plug valve. Spent catalyst distributes across the top of the regenerator bubbling bed through a riser and set of radial troughs.

Air, introduced into the regenerator through pipe grid distributors, burns coke off the catalyst. The regenerated catalyst exits the vessel bottom through a plug valve and is transferred from the plug valve well through a J-bend standpipe to the riser bottom.

Assembling the team

Conoco scheduled the turnaround for February 2001. About 2 1/2 years before the turnaround, Conoco assembled a team of FCC specialists as part of the technology improvement process.

The team evaluated short-range and long-term operational objectives and established these primary processing objectives for the 2001 turnaround:

- Preserve FCC unit profitability by maintaining conversion to more valuable products while processing a more aromatic gas oil feedstock.

- Operate within existing main air blower constraints.

- Ensure that modifications are compatible with any future projects to increase feed rate up to the existing coke burn limit.

The team considered other objectives, including improving unit reliability and minimizing unit downtime.

The team identified various options to improve operability and profitability, and grouped them into two categories: short-range (and low-cost) recommendations, which could be implemented either before or during the turnaround, and long-term recommendations to be implemented during the unit shutdown.

Short-range opportunities

The team identified and prioritized minor modifications and short-range opportunities that would immediately impact unit operability and profitability. These items focused on advanced process controls, catalyst activity changes, and expander and cyclone reliability.

The short-term changes implemented before the 2001 project with no capital resulted in immediate improved FCC profitability. This also shifted baseline unit performance for the 2001 project from the start-of-run in spring 1997 to a new test run base case in the summer of 1999.

Long-term opportunities

The team addressed process constraints and unit reliability issues when it identified long-term opportunities to be implemented during the turnaround. Specifically, the team evaluated the reactor riser mechanical integrity, new feed distribution technology, main air blower limitations, and catalyst circulation. One of the biggest challenges was to prepare the FCC unit to process a more-aromatic feedstock.

During the planning phase, the team identified the following long-term processing and reliability objectives (and associated solutions) for the turnaround:

•Maintain conversion and increase profitability:

- Install UOP Optimix feed distributors and replace the J-bend with a wye section and a catalyst acceleration zone.

- Optimize reactor-riser residence time.

- Address aromatic feedstock effects.

- Provide flexibility for future projects that would increase unit capacity by improving catalyst circulation with a second catalyst stripper (a new external spent-catalyst stripper).

- Minimize unit downtime.

- Operate within existing main air blower constraints.

- Improve mechanical reliability:

- Address reactor-riser refractory issues (hot spot in riser).

- Replace regenerated catalyst plug valve with state-of-the-art slide valve.

- Minimize project costs by giving full consideration to structural and space limitations.

- No increases in FCC stack emissions.

Feed distribution solution

Some of the more successful FCC unit projects in Conoco (including its Ponca City and Denver refineries) incorporated UOP's Optimix feed distribution technology. These revamps replaced the J-bend standpipe with a straight standpipe, wye section, and vertical reactor riser.

The wye section created the vertical riser and catalyst acceleration zone. A catalyst acceleration zone helps condition the catalyst to a moderate density and velocity before injecting the atomized oil to deliver optimum catalyst-oil contacting. Concurrently, the team optimized the vertical reactor-riser residence time based on expected unit operation.

The group proposed the Optimix feed distribution system (Fig. 2) to help Conoco achieve its processing goals.

Catalyst solutions

The project addressed catalyst circulation in addition to the process and reliability improvements that a new riser and feed distribution system would provide.

The original FCC unit had the spent-catalyst stripper and standpipe inside the reactor and regenerator. The spent-catalyst standpipe passed through the regenerator's center and opened into the middle of the distributor well, forming an annulus.

Any design modifications would be difficult, expensive, and time consuming due to complexity of the changes and because other major maintenance activities were scheduled inside the vessel. If this project was to minimize downtime, a unique approach was required.

The team of FCC specialists developed an innovative solution. Quite simply, a new external spent-catalyst stripper (Fig. 3) would be installed to unload the existing internal stripper.

A spent-catalyst stripper incorporating UOP's improved tray technology would be a key element of this revamp and would allow the FCC to circulate more catalyst and take full advantage of improved feed distribution and stripper technology.

Lift gas

Late in the project design, the team identified an opportunity to reduce steam use and sour water make in the FCC, both of which were approaching refinery limits.

Conoco installed relatively inexpensive piping and instrumentation to recycle gas-plant tail gas, thereby reducing some of the steam used as a riser lift medium. This provided the flexibility to decrease unit steam consumption when incremental wet-gas compressor capacity was available.

Project economics

With the technology upgrades clearly identified, the team turned its attention to project economics. UOP provided two separate yield estimates. For the reactor riser, regenerated catalyst standpipe, and feed distributor replacement, IAG estimated a total installed cost (TIC) of $5.9 million.

Yield improvements from the UOP Optimix feed distribution system technology would increase FCC unit profitability from the base case of processing a more aromatic feedstock in an unmodified FCC unit. The feed distributor, standpipe, and reactor-riser project (if completed as a standalone project) had a good internal rate of return (IRR).

The TIC estimate for the new external spent-catalyst stripper project was $1.4 million. Incremental yield improvements when adding the spent-catalyst stripper technology would also provide a good return.

Based on these forecasted economics, refinery management approved the technology upgrades.

Project execution goals

The foundation of any successful turnaround is a clear understanding of the project objectives. The team clearly identified FCC unit process objectives and established five project execution goals:

- Safety. Zero lost-work days, zero recordable cases, and zero first-aid cases.

- Quality. Material, workmanship, and operating performance.

- On time. All material on site before unit shutdown, turnaround completed on time.

- On budget. Minimum scope changes.

- Environmentally safe. No environmental releases during the project.

Project scope

The detailed FCC unit work scope began to take shape once the team established project execution goals. The project included:

- A new external spent-catalyst stripper (Fig. 3) using UOP's spent-catalyst stripping technology to increase stripping capacity and eliminate FCC catalyst circulation limits. The new stripper was designed to handle about 25% of the total catalyst circulation. This would allow the existing stripper to operate where it has been effective in the past.

- A new external spent-catalyst standpipe, slide valve, and expansion joint.

- A new spent-catalyst distributor, at the regenerator entry, compatible with the existing radial-flow trough distributor.

- A new regenerated-catalyst standpipe, slide valve, and expansion joint to replace the J-bend and internal plug valve to handle the higher catalyst circulation.

- A new riser wye section with a vertical catalyst acceleration zone and acceleration distributor.

- UOP's elevated Optimix feed distribution system (Fig. 2).

- A new reactor riser with crossover to the existing disengager.

Fig. 1 highlights the project scope with a "before and after" approach. Fig. 4 shows the new external stripper and new riser.

The team identified additional opportunities that were initially beyond the original project scope, including: continuous catalyst withdrawal, regenerator level control improvements, improving steam quality to many converter vessel taps, revising the plug valve pressure taps, and improving the spent-catalyst distributor trough aeration design.

Project implementation

Conoco held the FCC riser modification project kickoff meeting on Mar. 16, 2000. The meeting had all FCC unit turnaround participants in attendance: Conoco, IAG (project management, procurement), UOP (basic engineering, technology licensing), Atkins Benham Inc. (detailed engineering), and Construction & Turnaround Services LLC (construction).

The capital project team was led by IAG, which was charged with single-point responsibility to ensure that all efforts remained focused and on schedule. Conoco and IAG coordinated the integration of the capital and maintenance turnaround schedules.

The team reviewed the goals, objectives, and responsibilities of each team member during the planning phase so the turnaround would take place, as scheduled, in late February 2001.

This meeting served as the official start date for UOP's Schedule A basic engineering package. UOP would issue piping and instrumentation diagrams (P&IDs) and mechanical drawings within 8 weeks from this meeting.

Table 1 lists key project milestones.

With the preturnaround activities complete, oil was removed from the unit on Mar. 2, 2001. Mechanical activities started 5 days later due to deinventory issues. IAG managed the turnaround activities and Construction & Turnaround Services provided all of the required labor. Atkins Benham and UOP provided additional field assistance as necessary.

Using a team approach to project execution significantly minimized the demands on Conoco resources.

The duration of mechanical work during the turnaround was initially set at 31 days. Construction & Turnaround Services planned to work 6 days a week with two 10-hr shifts. This allowed the seventh day for critical-path activities and off-peak hours for X-ray.

Before this project, FCC start-up usually had the wet-gas compressor offline 4-6 hr with a flare that was noticeable by neighbors. This was not the case with the start-up immediately following the project.

Subsequent unit restarts have occurred with similar ease, mainly due to the new slide valve. Conoco operators appreciate and are impressed with the new flexibility designed into the FCC.

Project results

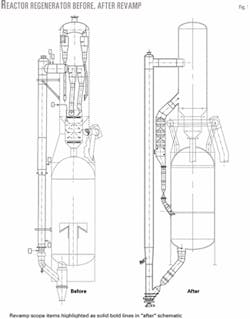

Table 2 summarizes improved unit performance following implementation of the short-range opportunities and technology upgrades installed during the turnaround. Table 2 also highlights the significant improvement achieved in gasoline yield and conversion. Gasoline yield increased 2.8 wt % and conversion increased 4.5 wt %.

The Optimix feed distribution system (the Optimix distributors and the catalyst acceleration zone) delivers these benefits. Operations during these tests indicate constant catalyst circulation with the new stripper in operation. Improved conversion also helps alleviate limitations in the slurry oil product rundown to storage.

With the new spent and regenerated catalyst standpipes, and the external spent-catalyst stripper, the unit is no longer limited by catalyst circulation. Essentially, the unit is operating at "new unit" design criteria. Since the time of the test run in Table 2, unit operation has been adjusted but has not yet reached its maximum potential. Conoco therefore continues to optimize the unit.

A lower regenerator temperature indicates that the severe afterburn that once plagued this unit was eliminated, which was part of the original project scope.

Additionally, replacing the plug valve and incorporating slide valve control of the catalyst circulation improved operability. Conoco can now control the reactor temperature within 1° F. vs. the previous "control" that allowed the reactor temperature to vary ±3° F. Also, the new slide valve improves reliability, accessibility, and makes routine maintenance easier.

In summary, the revamp met all FCC unit processing objectives. The turnaround:

- Maintained conversion and improved the value of the FCC yield slate when processing a more aromatic feedstock with improved feed distribution and spent-catalyst stripping technology.

- Addressed catalyst circulation and stripping efficiency, which provided additional unit flexibility.

- Did not increase stack emissions.

Conoco's overall project goals and objectives were met. Conoco values environmentally friendly operations and continues to pursue a "flare-less" FCC start-up.

The authors

Jacqueline D. McKinney is a six sigma black belt at Conoco Inc., Lake Charles, La. She has also served as senior process engineer with Conoco, Sunoco Inc., Amerada Hess Corp., Mobil Oil Corp., and Stone & Webster Engineering. She holds a BS (1982) in chemical engineering from the University of Texas, Austin. McKinney is a registered professional engineer in Texas.

William D. Henning is currently a consultant-FCC in the refining technology group at Conoco Inc., Ponca City, Okla. He holds a MS (1981) in chemical engineering from Kansas State University. Henning is a registered professional engineer in Oklahoma.