Mexican LPG pipelines juggle product mix with variety of end users

Mexico's Chiapas-to-Guadalajara pipeline plays a critical role in moving LPG throughout the country from large gas-processing plants, refineries, and import terminals. Its operations and management depend on constant awareness of the mixture that is in the line at any one time at any one point.

In Mexico, Petroleos Mexicanos (Pemex)-through its subsidiary Pemex Gas & Petroquímica Básica (PGPB)-produces, transports, and distributes LPG to authorized marketers.

It comes from many sources and has diverse properties and characteristics. And because the product origin and amount transported change constantly, the quality of product received at each terminal varies.

Consisting mainly of propane and butanes, LPG also contains other components such as olefins, methane, ethane, pentanes, and heavier hydrocarbons. The final mixture of each product is important to each consuming area because of the end use: industrial furnaces, heating stoves and burners, or automobiles.

As an example, in Mexico City LPG helps create tropospheric ozone, the area's main pollutant. In Guadalajara, LPG is associated more with suspended particulates. In automobiles, these variations have a direct relation to the temperature of combustion and, therefore, to parameters regulating polluting emissions.

Other locations using LPG are more affected by the vapor pressure or the specific gravity of the fuel.

This article analyses the quality, behavior, and results of using LPG in the Cactus-Guadalajara pipeline. It presents some specific cases of detected anomalies and the strategies to remedy them; the characteristics of the fuel at each injection and extraction point on the pipeline; and the environmental and technical situations in the different areas of the country that use LPG.

LPG in Mexico

LPG has been produced in Mexico since the early 1900s. It was 1946, however, before a plan was made to use it as a replacement for firewood and coal as a residential fuel, especially in urban areas.

LPG became more available by the 1960s, thanks to better processes and improvements in transportation. It now provides energy for three fourths of all Mexican homes.

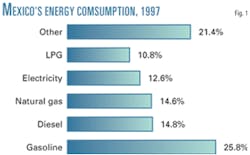

As called for in Mexico's energy plan, the National Balance of Energy of 1997,1 LPG covers 11% of the country's total energy demand, holding fifth place behind gasoline, natural gas, diesel, and electricity (Fig. 1).

It is increasing in importance in energy consumption for industry and transportation because it is a good alternative to the more traditional polluting fuels in metropolitan areas.

LPG is produced by PGPB's complex of gas processors (CPG) at Cactus and Nuevo Pemex in Tabasco and Chiapas; Cangrejera and Morelos in the Coatzacoalcos area of Veracruz; Matapionche and Poza Rica in northern Veracruz; and Reynosa, Tamaulipas. Since 1999, these seven complexes have produced an average of 200,000 b/d.

In addition, Pemex subsidiary Pemex Refinación (PREF) produces smaller amounts of LPG (33,000 b/d) as a by-product in its six refineries. This LPG is turned over to PGPB for transportation and sales.

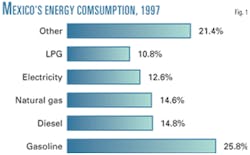

Mexico is normally able to produce about 75% of its LPG demand, but imports are becoming more important because of LPG consumption as motor fuel. Mexico imports about 95,000 b/d. That covers the rest of the national LPG demand, which rose to 329,000 b/d in 1999 from 101,000 b/d in 1980.2 This represents an increase for the period of 3.3%/year.

PGPB has met this accelerated growth in demand by investing in its production and transportation infrastructure. LPG demand growth has been faster than expected, however, and new facilities have been insufficient.

Fig. 2 shows how demand has grown in recent years.

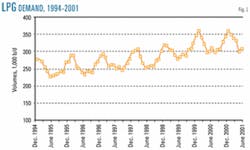

In order to guarantee continuous product deliveries to the consumer, PGPB developed a transportation network that includes more than 1,750 km (1,100 miles) of pipelines. One pipeline crosses the country from Cactus to Guadalajara, and another crosses the isthmus of Tehuantepec, connecting the ports of Pajaritos in Veracruz with Salina Cruz in Oaxaca. This allows the transport of product from the Atlantic Ocean to the Pacific without using the Panama Canal.

Nearly 70% of the LPG produced in Mexico uses these pipelines, which have been constructed to international standards.

To make LPG commercially available to the interior of Mexico, PGPB included 26 distribution terminals in its transportation system: 11 are on the pipeline network, 5 are marine terminals, and 10 are located in strategic points along the US border. The transportation and distribution network also contains 535 private bulk plants and 2,148 road tankers.

Pipelines are the most cost-effective means for both exporting LPG through the Pajaritos and Cactus terminals and importing propane across the border with the US (Fig. 3).

Supply and demand of LPG in Mexico varies, depending on the season. Most of the imports come in the winter when demand is higher.

Mexican LPG composition

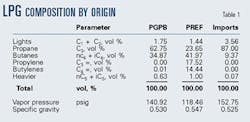

Because LPG is a mixture of different compounds, its characteristics vary depending on where it is produced. In Mexico, there are three basic compositions (Table 1).

Most gas-processing plants are in southern Mexico near the oil fields. And the farther product is transported, the more costly it is for the consumers. Therefore, it is difficult to compete in northern Mexico with imports across the US border.

LPG consumed in Mexico has three sources:

- Seven CPGs, which produce a very uniform LPG.

- Six refineries, with mixtures that can be very rich in butanes or alkanes (these contain double carbon ties, or olefins).3

- Imports through seven locations on the US border plus five ports on the Pacific and Gulf of Mexico.

The consumer is interested in the vapor pressure and to a lesser extent the combustion by-products generated. The sulfur contains the odorizing denominated mercaptan, no more than 140 ppm.

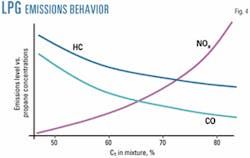

The atmospheric regulated emissions from product combustion are grouped into nitrogen oxides (NOx), unburned hydrocarbons (HC), and carbon moNOxide (CO).

In general, the more propane in a mixture, the higher the NOx emissions and the lower the HC and CO emissions (Fig. 4). This is due to the greater temperature of propane combustion.

LPG is a clean, efficient fuel whose combustion is always more than 98%. HC generation is low, while the burning temperatures are not high enough to generate a large amount of NOx.

Mexico City pollution

One of the main polluting agents in Mexico City is tropospheric ozone, which comes from many sources, including the use, handling, and burning of LPG.

As far as fugitive emissions of LPG are concerned, heavy olefins, butanes, and the presence of oxygen and solar radiation are greater ozone precursors than propane.5

That is why it is important to restrict the presence of propane.

Nevertheless, studies by Instituto Mexicano del Petróleo (IMP) and others3 5 agree that emissions from LPG in motors and burners help form tropospheric ozone through the generation of nitrogen oxides.

From an ecological point of view, the ideal hydrocarbon mixture must stay within 60-70 vol % propane. Higher concentrations contribute to greater flame temperature and therefore to a greater contribution of NOx. Lower concentrations promote greater unburned hydrocarbons and carbon moNOxide.

Although both polluting agents together do not surpass 15% of total ozone in Mexico City, the control of these variables will lessen this problem.

Studies in Guadalajara and Monterrey indicate that, because these conditions do not normally prevail there, this LPG chemical composition does not apply. These cities have different atmospheric conditions than Mexico City, and use of LPG there does not seem to contribute to the problem.

As are other hydrocarbon compounds consumed in Mexico, LPG is controlled according to official Mexican standards established in Table 12 of NOM-086-ECOL-1994. This standard establishes the ecological quality of liquid and gaseous fossil fuels used in all fixed and mobile locations.

It states that the fuel must keep within a series of parameters, one of which is vapor pressure. The standard, which has been in use for a few years, states that fuel must have a vapor pressure between 5.6 and 14.1 kg/cu cm (80-200 psi). The standard does not mandate chemical compositions of the product.

In 1997, after a study by PGPB and IMP of the air quality in Mexico City and its relationship to LPG,5 the National Institute of Ecology published a new standard that established environmental protection specifications for LPG when used in fixed locations in Mexico City.

It also takes into consideration the parameters indicated in Standard NOM-086-the presence of propane (more than 60 vol %), butane (40% maximum), olefins (2% maximum), and a higher vapor pressure (8.4-14.1 kg/cu cm; 120-200 psi).

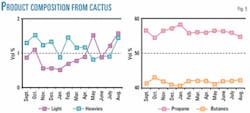

Pipeline characteristics; imports

The composition of the LPG changes very little at its origin at Cactus and Nuevo Pemex complexes in southeastern Mexico. The LPG stays about 60% propane, 40% butanes, 1% light products, and 1% heavy products (Fig. 5).

On the other hand, the complexes at Cangrejera and Morelos in the state of Veracruz receive a C2+ product, which is separated into different streams emphasizing the butane mixture, propane, pentanes, and heavier (Fig. 6).

After production, the feedstock moves by pipeline to the refinery at Minatitlán for separation into n-butane and iso-butane, which are used in the production of methyl tertiary butyl ether (MTBE). The pentane stream is exported as natural gasoline.

Finally, the propane stream is stored and later either distributed as LPG in the region through the terminal at Pajaritos or added to the LPG pipeline.

As far as the butane is concerned, PGPB could produce excessive amounts in its plants, and it could be shipped the same way as propane.

The quality of product injected into the LPG pipeline originating at these complexes varies in content between 3 and 40 vol % butanes.

The refrigerated terminal at Pajaritos routinely receives cryogenic LPG shipments, which have a typical composition of 90% propane and 10% butanes, known as "HD-5."

The LPG is stored in cryogenic tanks within the terminal facilities. The product later is sent to heat exchangers to raise its temperature to 5° C. from -33° C. before being injected into the LPG pipeline.

Refinery use

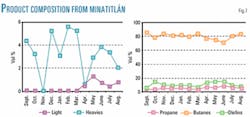

The refinery at Minatitlán takes the butane mixture from Cangrejera and Morelos, separates it, and uses the i-C4. The n-C4 is stored in spheres at ambient temperature along with other distillation streams from the different processes. Normally, this mixture, rich in butanes, is then sent to the LPG pipeline (Fig. 7).

After Minatitlán, the LPG pipeline receives no more additions in order to keep the quality of the stream constant from this point to the refinery of Salamanca in Guanajuato.

After the injection at Minatitlán, part of the total stream is sent through a branch to the refrigerated terminal at Salina Cruz.

At its arrival, the product is cooled and later transferred through vessels to the terminals at Topolobampo, Sinaloa, and Rosarito, Baja California. Product is sometimes exported to Peru and Ecuador when the price of the product and volume of production are adequate.

On the way to Guadalajara, the terminals at Tierra Blanca, Vera Cruz; Puebla, Pue.; and San Martin, Texmelucan, extract product to supply their regions.

San Juan Ixhuatepec terminal diverts part of the flow to private plants for distribution north of Mexico City. The Tula terminal receives part of the LPG, which is stored and mixed with refinery production.

Fig. 8 shows that the final Tula mixture is rich in light products and olefins. And because the final mixture of both these streams usually contains more than 2% olefins, this terminal does not supply product to Mexico City.

The Tepeji terminal in Hidalgo receives LPG and distributes it by trucks, mainly to Mexico City.

Along with the Puebla and San Juan terminals, this helps satisfy Mexico City's demand.

Later, the Salamanca refinery adds a small amount of product rich in olefins.

That is why the final mixture in the LPG pipeline again varies in its composition, having higher amounts of prop ylene, which causes higher vapor pressure in the product. It is extracted at the Abasolo terminal in Guanajuato and Zapopan in Guadalajara.

Watching the composition

It is impossible to know the LPG composition at any one time and point in the pipeline because it varies constantly.

Mixing in storage at the terminals and distribution plants, however, makes the composition more uniform.

PGPB must constantly watch and control the composition of LPG at its injection and extraction points. For instance, a high vapor pressure could generate cavitation during transport, eroding the pipe walls.

Also, variations in composition could affect filtering equipment and therefore emissions from engines, which depend on proper carburation and adjustment. This would contribute to atmospheric pollution in the cities.

References

1. Secretaría de Energía, Balance Nacional de Energía 1997, México, 1998.

2. Pemex, Base de datos Institucional, 1999.

3. Schifter, Isaac, Usos y abusos de las gasolinas, Fondo de Cultura Económica, México, 1998.

4. Baskákov, A.P., Termotecnia, Ed., MIR, Moscow.

5. Efecto de los componentes del gas licuado de petróleo en la acumulación de ozono en la zona metropolitana de la Ciudad de México, México, 1997.

The authors

Miguel Bueno Fernández is manager of business planning for Pemex Gas y Petroquímica Básica (PGPB) in Mexico City. He began his career with Pemex in 1983 working in international crude and petroleum products trading. He has held positions as commercial manager in Pemex's London office, commercial crude petroleum manager, and manager of petroleum product operations. He holds a degree in industrial chemical engineering from National Polytechnical Institute.

Fernando García Rubio Ortiz is sub-manager of regulations and resources evaluation for Pemex Gas y Petroquímica Básica's process analysis and control department. Has worked for the Pemex organization for 18 years, the last 5 with PGPB. Prior to Pemex, he was a professor on the faculty of Estudios Superiores, Cuautitlán, Universidad Nacional Autonoma de México (UNAM). He holds a degree in chemical engineering from UNAM and an MS in science from Instituto Politécnico Nacional.

Luis E. Ontiveros Padilla works in LPG project evaluation and development for Pemex Gas y Petroquímica Básica, Mexico City. He is responsible for promoting and coordinating environmental studies related to LPG projects. He previously worked on a variety of research projects in Spain for Repsol Oil Co. He holds a Phd in mechanical engineering from Universidad Politécnica de Valencia in Spain.