Flow-activated circulating tool aids offshore wellbore cleanup

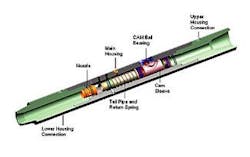

Here's the new flow-activated circulating tool (FACT), which is designed to improve the cost-effectiveness of offshore wellbore cleanup operations.

FACT provides an alternative to the traditional ball drop and weight set tooling options. The circulation rate is used to control the tool position via an orifice choke, a spring-loaded tailpipe, and a cam mechanism within the tool. The tool can be run in either a normally closed or normally open condition.

The cam profile helps ensure that the tool is not primed for activation until a simple sequence of flow rates has been executed, thus permitting circulation at high flow rates with the ports in both the open or closed positions.

The cam also provides a mechanism to restore the tool to its initial running configuration, allowing the tool to be cycled an unlimited number of times without retrieval for redress.

The orifice choke size can be selected to govern the flow rate required to activate the tool, maximizing the operating envelope within which the tool can be deployed.

Source: UWG Ltd., 1718 Fry Rd., Suite 475, Houston, TX 77084.

New framework imports, exports data quickly

An enhanced technology architecture recently introduced is designed to im prove the speed and efficiency of integration with customer legacy applications, compatible with most common integration frameworks.

The new Synchrion interoperability framework has the ability to tie in to industry-specific technical and design applications such as upstream energy tools for designing stimulation and cementing services, operational databases such as drilling information and daily reporting systems, and applications that connect to invoicing, joint interest billing, and run-ticket software systems.

Synchrion provides prebuilt, configurable gateways through which any of this firm's software products can be matched with customers' existing software infrastructure, creating an environment that allows the dynamic import and export of data between products from this firm and virtually any other modern software application.

Source: Wellogix Inc., 1160 Dairy Ashford, Suite 400, Houston, TX 77079.

New oil field control valve

The new D2 FloPro control valve is a member of the new FisherExpress family of oil and gas patch control products.

These features come standard: 1-in. NPT end connections, ASME Class 900 (2,250 psig) pressure rating, FloPro field-selectable flow rate; solid Alloy-6 erosive service trim, full pressure drop capability, ENVIRO-SEAL D2 packing system, low temperature (-50° F.) materials, field-reversible actuator, and corrosion-resistant powder coat paint.

While it is handy as a dump valve on gas separators and scrubbers, the D2 FloPro is also suited for other high-pressure applications in natural gas production, compression, and processing, the company says.

The valve weighs 17 lb.

Source: Emerson Process Manage ment, Fisher Controls International Inc. Div., 205 S. Center, Marshalltown, IA 50158.

New remote monitor for cathodic protection

This new LaBarge Inc. ScadaNET Network is a wireless remote monitor ing system for cathodic protection operations.

It uses control channels of the existing cellular network to monitor status and alarm conditions at cathodic protection rectifiers.

System status is monitored via the internet, and alarm conditions are sent via e-mail, fax, pager, or voice dialer.

There are no long distance charges or fixed monthly fees.

Source: Farwest Corrosion Control Co., 1480 W. Artesia Blvd., Gardena, CA 90248.