Equipment/Software/Literature

Gas-liquid separator offers +99% efficiency

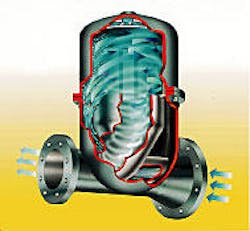

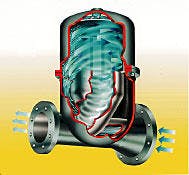

Wright-Austin Type T gas-liquid separators now have entrainment removal efficiencies that exceed 99% over the entire flow velocity range for which the separator was designed.

Used in air, steam, or gas service, the separators remove moisture and free liquid droplets from this flow. An exclusive vortex containment plate design helps prevent reentrainment and helps eliminate the need for complex baffles or deflectors that can obstruct the flow stream. This design assures the output of completely clean and dry air, steam, or gas with very little line pressure loss, the maker says.

The Type T gas-liquid separator is available in several models for application flexibility. The basic one has a reservoir where the entrained liquid collects for draining. The Type ST is an economical, high quality combined separator-and-trap. In this model, the entrained material is directed to a trap mechanism that is an integral part of the separator. This trap incorporates a foolproof design that automatically ejects the condensate when it reaches a predetermined level. Tests show that these units will remove more than 99% of entrainment and particulate down to 10 microns, with almost no loss of line pressure.

Separators are available in iron, carbon steel, and stainless steel with either threaded, flanged, or butt-weld piping connections for pipelines up to 4 in. in size. The units are compact and can be self-supporting when installed.

Source: Hayward Industrial Products Inc., 900 Fairmount Ave., Elizabeth, NJ 07207.

New track burner for steel plate

A new track burner burns steel plate with portable oxy-flame or plasma-cutting devices.

Standard angle iron can be used for track rather than special rails, and cutting distances are virtually unlimited, the firm points out.

Tracking speeds are fully adjustable, and the torch position is set with a precision rack and pinion gear set.

Source: Watts Specialties Inc., 800 Fife Way, Milton, WA 98354.

Marine fire suppression system

Here's the new H-Series engineered marine fire suppression systems with FM-200 extinguishing agent.

Systems are designed for workboats and offshore platforms. These systems help protect complex engine and generator compartments, bilges, communication centers, machinery spaces, paint lockers, and electrical areas. They are also engineered to achieve maximum extinguishing agent concentration in 10 sec or less, with no residue cleanup required.

The elements of H-Series engineered systems, such as modular use of cylinders and stackable valve components, can be configured to accommodate spaces ranging from 1,500 cu ft to 17,500 cu ft. The systems are easy to assemble and service, requiring few if any replacement parts when they need to be recharged, the company notes. Mechan ical valve assemblies are made from corrosion-resistant brass. And FM-200 extinguishing agent is suited for use in compartments that contain sensitive electronic equipment or where people are present.

Source: Sea-Fire Marine, 9331-A Philadelphia Rd., Baltimore, MD 21237.

Ell provides fast, easy repair of leaks

Here's the PLIDCO split+repair ell. It's designed to stop and repair leaks in pipe line ells quickly.

It is installed by bolting the two halves over the leaking ell.

Provisions for venting or sealant injection can be included.

Factory-installed packing is held in place by patented steel girder rings that prevent displacement during installation.

Available packing includes Buna-N, Neoprene, Viton, Kevlar, and silicone. Fittings can be seal-welded if required.

Ells are stocked in size ranges of 11/2 through 4 in. Sizes 11/2 in. and 2 in. are rated for 1,000-psig working pressure. Other sizes and pressure ratings are available, as well as different angle de grees.

Source: Pipe Line Development Co., 870 Canterbury Rd., Cleveland, OH 44145.