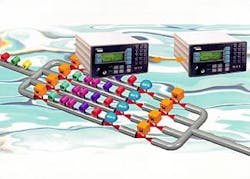

Flow computers available with hot duty/standby option

This firm's multistream liquid and gas flow computers now come with a hot duty/standby option. The new feature allows full redundancy to be built into the system using two flow computers for as many as four meter runs and is suited for fiscal and custody transfer monitoring applications.

The hot duty/standby feature synchronizes the logging of flow data between two multistream flow computers for seamless handover in the event of a failure.

Both computers are connected to each metering point. One computer is designated as the main monitoring device (duty) and the other as the backup (standby).

Automatic synchronization of the two machines takes place at startup and at user defined intervals during operation. In the event of a failure of the duty computer, alarms are raised, a handover takes place, and the standby system becomes the duty device automatically. The accuracy and integrity of the flow data are maintained without losing any flow.

The new feature includes high integrity communications functions that help ensure error-free handover. System integration is kept simple because the software handles all communications addressing issues, so the address of the duty computer remains constant, even after handover.

In addition, the use of multistream flow computers aids the management and analysis of flow data. Rather than having to collect results from a number of single-stream computers, totalized flow data are available immediately for analysis and reporting, the company points out.

Source: Solartron Mobrey, 19408 Park Row, Suite 320, Houston, TX 77084-4860.

Monitor warns of mechanical failure, flow disruption

The Ultra-Trak 750 passively monitors structureborne ultrasounds produced by operating equipment. It can be set to detect either a rise or dropoff of sound levels in real time for trending or alarm purposes.

Typical uses include early warning of mechanical failure, valve leakage, flow disruption, cavitation, equipment shutdown, and arcing in enclosed switchgear.

The ultrasonic monitor may be used to monitor, trend, or data log events. One feature is a demodulated output that allows the sensor to be connected to FFT analyzers and other recording devices. Utilizing a 4-20 ma current loop power or current loop output, it can be connected to alarms or recorders. A range of 120 dB and sensitivity adjustments provides users with the capability of sensing subtle to gross changes in operating equipment. The monitor senses ultrasound centered around 40 khz. Because of the short wave nature of these high frequencies, monitored signals are localized to the immediate area reducing the possibility of false alarms from remote sources.

The unit is housed in a stainless steel, water resistant, and dustproof enclosure. Baseline sensitivity threshold levels are set through a programmable sensitivity adjust.

Source: UE Systems Inc., 14 Hayes St., Elmsford, NY 10523.

Motor designed for downstream operations

The new Energy $aver X$D Ultra extra severe duty motor line is available for use in downstream process operations.

The motor is manufactured and precision balanced to 0.04 IPS overall. The motor has a bearing system that's designed to provide superior bearing life, Class H insulation components throughout for better thermal resistance, and a lower running temperature for long life. The maker says these improvements also allow for smaller, more efficient fans, reducing noise, and in turn, create a quieter motor.

The motor is designed to NEMA B specification standards. It not only has NEMA B torques, it also meets NEMA B starting current specifications. This helps assure that users can upgrade from other motors without stressing electrical distribution systems.

Source: GE Industrial Systems, Box 2204, Fort Wayne, IN 46801-2204.