Tie-in system uses low-cost flanges on deepwater Girassol development

TotalFinElf SA’s Girassol deepwater project started up off West Africa in December 2001. Stolt Offshore SA’s application on Girassol of its modular advanced tie-in system (MATIS) using low-cost flanges represents the kind of technological advance that is making deepwater and ultra-deepwater developments, particularly subsea tie-ins, economic and efficient.

In general, capital expenditure (CAPEX) for subsea tie-back projects in deepwater is evenly split between the wells and the flowlines.

Consequently, reductions in the costs of the flowlines can affect the economics of a project.

Flowline costs consist of line pipe and coating, installation, and tie-in. Line pipe costs and installation costs are subject to market forces. It is possible, however, to influence costs associated with the flowline tie-in through selection of the tie-in method.

For deep and ultra-deepwater field developments, remote flowline tie-in methods are essential.

To date, the several proprietary remote flowline tie-in systems available to the industry have required use of complex mechanical connectors, which are expensive and limit operator flexibility.

To address this cumbersome and costly approach for deepwater tie-ins, Stolt Offshore developed MATIS (Fig. 1), making flangescommonly and successfully used in shallow-water installationsefficient and economic for remote tie-in requirements of deepwater flowlines.

Girassol

Applying its MATIS research initiated in 1994, Stolt Offshore installed standard flanges for a number of projects off Norway before successfully completing 52 flange connections in up to 4,757 ft of water for the Girassol project, off Angola.

Following first production on Dec. 4, 2001 (OGJ, Mar. 18, 2002, p. 53), the Girassol field has already reached its production plateau of 200,000 bo/d from 8 wells. A total of 39 subsea wells will be connected to the FPSO by mid-2003: 23 oil producers; 14 water injectors, and 2 gas injectors.

The oil-producing wells are characterized by their high deliverability, with individual production rates in the range of 30,000-40,000 bo/d possible. Total investment for the Girassol development is $2.7 billion.

Stolt Offshore’s project scope has included a joint venture with Bouygues Offshore SA for development of the Girassol floating production, storage, and offloading (FPSO) unit and of the subsea systems. The world’s largest FPSO to date, the vessel can store 2 million bbl of oil and can produce 200,000 bo/d.

Technology for deepwater

For many years, flanges have provided industry worldwide with low cost, high-integrity connections for subsea pipelines in shallow water. To this extent, the industry has a vast amount of knowledge and experience on the long-term performance of this type of joint.

Traditionally, divers have completed the flange connections for shallow-water projects. With development of specific remote tooling systems, however, such as MATIS, operators can apply the advantages and cost savings associated with diver-installed flanged spool pieces to the tie-in of deepwater pipelines.

The first prototype, which Stolt Offshore developed jointly with bolt-tensioning specialists Hydratight Sweeney Inc. under the EC THERMIE program, was successfully demonstrated in 1997.

Since then, Stolt Offshore has developed MATIS into a commercial flange connection tool, which is remotely operated with no umbilical required. For deep and ultradeepwater applications, Stolt Offshore’s Deep MATIS system receives all of its power and communications via a standard workclass remotely operated vehicle (ROV), connected to the unit (Fig. 1).

Flexibility; advantages

Standard flanges for deepwater tie-in applications provide operators with increased flexibility and with several significant advantages over mechanical connectors, thus reducing the overall installed cost for deepwater tie-ins.

Those advantages include:

- Subsea flanges are high-integrity joints, with a quantifiable reliability on projects worldwide.

- Lead times for ordering flanges are relatively short, taking mechanical connector supply off the critical path. Flanges also are available from a large number of suppliers.

- Bolted flanges are the most tolerant connection with regard to stress, making them the only connectors that can withstand a significant applied moment.

- The use of flanges precludes the need for a site integration test (SIT) during the fabrication of the subsea equipment.

- The use of a bolted swivel flange eliminates the need for control of pipeline orientation and induces no torsional stresses in the pipeline.

- Flanges are available in all sizes and pressure ranges, whereas mechanical connectors may have some limitations for large-diameter applications.

- Major modifications to subsea structures are not required for the remote connection of flanges.

- The use of flanges helps to simplify spool design, eliminating the need for the vertical loops required in the commonly used "U" spools and improving flow assurance at the base of risers.

- Fabrication and alignment tolerances for spools using flanges can be significantly increased, reducing the risk of poor fit-up and expensive modifications in the field.

- For flowlines with production chemistry issues, flange joints can be insulated after connection with a simple cover arrangement.

- Flanges are available for flowlines when the fluid characteristics require corrosion-resistant materials.

Testing

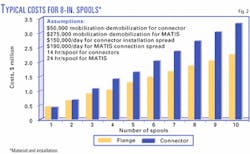

The overall tie-in costs further validate the use of flanges for deepwater flowline tie-ins. In a comparative study of flanges and mechanical connectors for deepwater application, Stolt Offshore used an 8-in. diameter flowline as a deepwater basis and estimated overall tie-in costsincluding both material and installationfor spool piece tie-ins (Fig. 2).

With the flange spool piece connected with the MATIS equipment, Stolt Offshore assumed higher installation costs compared to the mechanical connector. This increase includes higher costs for mobilization, installation spread rate, and a longer duration for the spool piece connection (Fig. 2). The results of this exercise show an equivalent cost level for flanges and mechanical connectors when one spool piece is used.

As the number of spools increases to a level more typical of subsea development projects, however, flanges become significantly more cost-efficient than mechanical connectors.

A similar exercise for varying sizes of flanges and connectors also has significant results.

Here, the overall costs are estimated assuming a small tie-in project with four spools against cost variation as the flowline diameter increases.

Again, significant increases in the overall tie-in costs appear (Fig. 3).

In fact, Stolt Offshore has found that the bigger the size of the connection, the greater the potential savings. For example, use of standard flanges on a 30-in. export pipeline connection could produce savings in the order of $3.5 million compared with remote mechanical connectors.

Remote connection

MATIS is designed to make-up standard ANSI, Taperlok, and API flanges remotely. In several configurations, the system can perform tasks such as lay down head removal, manifold-to-spool piece tie-in, flowline tree connections, and vertical connections to risers.

Currently, MATIS can connect flanges within the range of 4-36 in. in diameter, with a maximum depth rating of 9,843 ft.

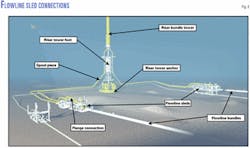

MATIS includes two main components: the flange alignment frame (FAF) and the MATIS deployment frame (MDF; Fig. 4).

The FAF provides the fine alignment of the flanges and consists of two claws at either end to grab the pipe and spool and perform the flange alignment.

The FAF has an open center to locate the MATIS deployment unit. For situations in which one end of the spool is fixed, for example a tree or manifold connection, the FAF can be configured with one claw to reduce weight.

The MDF carries all the consumablesbolts, nuts, and gaskets required for the flangeand is used to insert the bolts into the flange, insert the gasket, apply the required tension, and connect the nuts.

The gasket can be preinstalled into the flange or fitted as part of the connection operation, as the MDF has the facilities to insert and remove the gasket. The MDF consists of a crash frame, which houses the bolt-tensioning equipment, and the systems for inserting the consumables.

MATIS is deployed and handled in different ways, depending on the water depth and flange size to be connected. For shallow-water units, FAF and MDF are deployed individually and can be controlled by a dedicated umbilical.

For deep and ultradeepwater applications, a specific Deep MATIS system (Fig. 1) includes some specific features. The FAF and MDF are connected together and deployed as one unit to reduce the deployment times.

Once lowered to the seabed, the deep unit relies on a dedicated ROV for power and electronic interface to minimize the number of down lines, an important factor in simplifying deepwater construction operations. In the case of Girassol, or any ultradeepwater venture, this point is particularly important, considering that it takes 3 hr to lower anything to the seabed, and, of course, 3 hr to retrieve equipment and tools back to the support ship.

To complete the work, the Deep MATIS system is equipped with two carrousels on either side of the MDF, with each holding sufficient nuts and studs to perform three flange connections.

This operation requires a system of pick-and-place arms to retrieve the bolts from the carousel and insert into the flange.

Deepwater success

In 2001, Stolt Offshore successfully completed the first phase of the spool piece tie-in work at the Girassol field using remote flange connections. Working from Stolt Offshore’s dynamically positioned vessel Seaway Explorer (Fig. 5), the project involved the use of 36 spool pieces, most longer than 381 ft, to link the seabed flowline bundles to the bases of the riser towers at one end with the manifolds at the other.

The installation program included connection of 39 flanges in the horizontal position, on the top of the flowline sleds, and 13 flanges at the base of the riser bundle towers, which were in the vertical position (Fig. 6). The program used two sizes of flange, 9 in. and 13 5/8 in., both standard API with a 5,000-psi pressure rating.

Stolt Offshore preinstalled all of the spools and achieved the coarse alignment with a set of simple flange catchers welded on the flowline sled.

In this case, the Stolt Offshore crew set the Deep MATIS unit to be neutrally buoyant and lowered it to the seabed in a deployment frame (Fig. 7). Once the unit was on the seabed, the crew docked the ROV to it, released it from the deployment frame, and transferred it to the flowline sleds.

The crew then latched the MATIS unit to the top of the flowline sleds, where the flange connections are located. The unit, equipped with a set of reaction claws, then gripped the spool and maneuvered the two flange faces into position.

With flange faces aligned and the gasket inserted (Fig. 8), the Explorer crew loaded studs and nuts into the connection system using the pick-and-place arms. Equipped with the necessary consumables, the MATIS unit readied the three flanges, inserting the bolts individually. The unit then tensioned the flanges and ran the nuts onto the studs.

At the end of the operation, the Seaway Explorer crew either transferred the unit back to the deployment frame and returned it to the surface or moved it across to the next flange on the flowline sled.

For the vertical flanges, the Stolt Offshore crew docked the MATIS unit to the riser tower structure using a module at the unit’s front end. Once in position, the crew rotated the complete unit 90° and completed the flange alignment and bolt connection in the vertical plane.

The tie-in work at Girassol provided a major test for the MATIS equipment and the operators controlling the system offshore.

As could be expected with this type of complex subsea operation, the project team experienced a considerable learning curve, thus affecting the efficiency of the operations at the beginning of the Girassol program.

As the program progressed, however, the experience gained helped to improve the time required to complete the flange connection operation. With both MATIS units working, the average connection time was around 8 hr with the fastest at 4 hr.

Deployment of the MATIS equipment does not require use of a large subsea construction vessel. The Seaway Explorer, as used on Girassol, is a relatively small (length 262 ft) dynamically positioned ship, fitted with a stern A-frame.

The MATIS equipment also can be deployed from an anchor-handling vessel fitted with two ROVs.

Another site

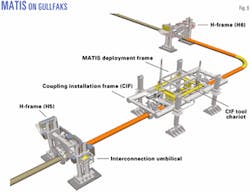

Stolt Offshore can interface MATIS with other pipe-handling systems. For example, as part of the recent Gulfaks tie-in work, the MATIS deployment frame interfaced with the pipeline handling equipment, forming part of the Statoil pipeline repair system.

Depending on the nature of a tie-in operation, the tie-in may require the use of pipe-handling frames to achieve the initial alignment of the spool piece. This procedure is similar to that adopted by divers for shallow water tie-in operations and is particularly effective for spool pieces with larger diameters.

Stolt Offshore has applied MATIS to perform tie-in operations on a number of deepwater projects in both the North Sea, as well as its newest achievement on the Girassol project.

In October 2000, Stolt Offshore used MATIS successfully to connect four flanges, ranging 22-24 in. in diameter, in 705 ft of water as part of a subsea tie-back at the Statoil Gulfaks field off Norway.

In this situation, the units were deployed heavy and landed directly over the flanges.

Stolt Offshore used the CIF frame from the Statoil pipeline repair system together with pipe alignment frames to bring the flanges together (Fig. 9). The project team then lowered the MATIS deployment frame, preloaded with all the studs and nuts, and positioned it inside the CIF frame. A system of podger bars turned the swivel flange to align the bolt holes.

The team then advanced the stud-loading system and inserted all the bolts into the flange together (Fig.10). The bolts were then tensioned and the nuts run onto the end.

All the information relating to each individual flange connection, such as bolt tensions and the number of turns given to each nut, is thus recorded and stored, giving a complete record of all the important flange connection parameters. F

The authors

Vincent Alliot is manager of Stolt Offshore SA’s technology division. Based in Nanterre, France, he has more than 20 years’ experience in the offshore oil and gas industry. He served as installation engineering manager of the TotalFinaElf SA Girassol project and is inventor or coinventor of several industry technology tools, including the hybrid riser and the bundle flowline concepts developed for Girassol. Alliot holds a mechanical and electrical engineering degree from Arts et Metiers of Aix-en-Provence in France.

Ian Frazer is group research and development manager for Stolt Offshore, responsible for the company’s worldwide management and coordination of technology development activities. Based in Aberdeen, he has more than 20 years’ experience in the offshore oil and gas industry, with specific emphasis in the UK and Norway business markets. Before joining Stolt Offshore in 1998, Frazer worked for Conoco UK Ltd. in several capacities, including project engineer for the Banff field FPSO development and pipeline systems supervisor for the Heidrun field development project. Frazer is a chartered engineer with a BSc and PhD in civil engineering from the University of Salford, UK. He is a member of the Royal Institution of Naval Architects.