Unocal focuses on ‘people’ factors to improve deepwater drilling performance

In recent years the petroleum industry has relied heavily on technological advancement for the much-needed improvement in its drilling efficiency.

That is particularly true in the high-cost ultradeepwater drilling arena, where the players have access to new technologies, such as fifth-generation drill rigs, dual-gradient drilling systems, advanced synthetic-base mud, rotary drilling tools, and expandable casing.

While state-of-the-art technology is a necessary ingredient in breakthrough performance, because of its relative availability, technology alone will not set a company apart from the pack. The company that wants to distinguish itself as the industry leader in drilling must turn to other means.

Unocal believes that industry-leading drilling performance goes beyond technology to ‘people’ factors, such as team integration, work environment, a shared culture, and meaningful processes.

The idea that people factors can influence performance is not new to the industry. What is new is Unocal’s relentless focus on these factors, its systematic application of an eight-point ‘drilling excellence’ philosophy, and the results that the company has achieved.

When applied in the deepwater Gulf of Mexico, this drilling excellence philosophy has resulted in outstanding drilling, safety, and environmental performance. Its success has been so significant that Unocal is implementing the philosophy at company operations worldwide.

The company had sown the seeds of the drilling excellence philosophy in the waters off Indonesia and Thailand, and in the Gulf of Mexico, where Unocal has had a major presence for decades.

With time, this philosophy has evolved into a corporate drilling culture that achieves increasingly positive results as it is further honed and developed.

Philosophy’s origin

In 1995, Unocal launched an effort to improve its exploration success off Indonesia.

While the company had managed to reduce development drilling costs in the area by 20-30%/year, exploration costs remained high. Unocal hit on the idea of applying the techniques it had used to improve its development results to exploration operations.

The overarching goal was to maximize the number of exploration wells drilled and minimize costs. The strategy was to optimize well design and data collection, drill ‘expendable’ wells, accept some failure to reach TD, and execute the wells with a sense of urgency.

The hope was that the application of a new ‘saturation exploration (SX)’ philosophy would lead the Indonesia exploration team to strike the optimal balance between these factors and the application of technology.

The team used second-generation semisubmersible rigs with a surface BOP (blowout preventer) and prelaid mooring systems, drilled slimmer holes, ran fewer casing strings, ran only value-adding logs, and eliminated much of the conventional coring and drillstem testing.

In the first year that the SX philosophy was applied, Unocal Indonesia drilled 30 shallow-water exploration wells, compared to the previous average of 5-6 wells/year. It also cut average exploration well costs from $5.2 million to $1.3 million while meeting the exploration campaign objectives.

In the 5 years that followed, Unocal expanded the use of SX and surface stack drilling techniques to the deep water off Indonesia with even more impressive results.

Philosophy development

The success of the SX philosophy led Unocal to search for a method of applying this basic concept in other settings.

But while the name SX had become closely linked with Unocal’s successful operations in Indonesia, Unocal’s operations in Thailand, the Gulf of Mexico, and other areas were also posting outstanding results.

So, Unocal took the lessons learned by drilling teams across the globe and used them as the foundation for building the drilling excellence plan.

The drilling excellence plan is a framework that enables a drilling organization to achieve extraordinary results in any setting, whether shallow water, deep water, desert, jungle, or arctic environments.

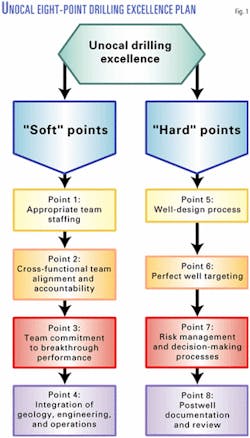

The plan consists of the following people concepts and processes: team staffing, team alignment and accountability, team commitment to breakthrough performance, team integration, well design, perfect-well targeting and benchmarking, risk management and decision-making, and G&G (geological and geophysical) and postwell documentation and review (Fig. 1).

Team staffing

Unocal typically approaches the team-building task by determining the team size and structure, defining the skill sets required, and finding people with those skills.

When building a high-performance drilling team, we bring together people with a wide diversity of geographical and operational experience. Further, we go beyond that, looking for the right blend of personalities that will result in the kind of team chemistry that fosters a real esprit de corps among the team members.

Joining these factors together in a team makes for a powerful combination that can generate outstanding results.

Team alignment, accountability

Before the company plans and executes a well, the entire cross-functional team must accept joint accountability for the project outcome. Each team member must accept responsibility for achieving objectives, minimizing costs, operating safely, and complying with environmental regulations.

Unocal’s drilling excellence plan features several processes and standards designed to achieve joint accountability. One of these processes is an initial ‘accountability conversation’ that takes place in a dedicated team meeting.

As part of this conversation, the team has a ‘dependency discussion’ in which team members reveal what they need from one another in order to carry out their work in an optimal fashion.

This conversation ensures that the entire team fully understands the drilling mission, from mud line to TD, and accepts accountability for the outcome. Once this 360-degree accountability is achieved, the team can plan and execute the well in earnest.

Team commitment

After the company has achieved team alignment and accountability, the team members are ready toand they mustmake a commitment to achieve breakthrough performance.

Before planning or executing a project, the team must believe that breakthroughs are possible and that together they will find ways to achieve extraordinary results.

This mentality, when combined with enabling processes and standards and strong-management support, becomes a key ingredient in the ongoing delivery of exceptional drilling results across Unocal’s worldwide organization.

Team integration

The drilling excellence plan centers on the integration of geosciences, engineering, and operations into a cohesive unit, focused on the drilling mission.

In building the deepwater Gulf of Mexico exploration team, Unocal moved the team-building concept beyond the drilling group to the geosciences group, integrating them both into a cross-functional team.

Unocal then took certain major subcontractorsproviders of mud, cementing, and directional drilling services, for exampleand integrated them into the team.

It is important to note that team integration involves more than simply moving desks. It is a concept that has to be built into the culture of an organization.

Unocal achieves effective team integration by applying rigorous processes and standards. The company facilitates communication through colocation and dedicated team meeting spaces.

Morning meetings include the entire cross-functional team, rather than just the drilling team. The team also uses a very specific process that facilitates collaboration and ensures consistent documentation and follow-up communications.

Meeting and interacting in this manner ensures that everyone on the team knows exactly what is happening on the project, and going forward, what the plan is.

Team integration does not stop at the office door but extends to the rig as well. Company geologists and geophysicists spend considerable time on the rig, in a designated operations center that is located next to the mud-logging unit.

The center provides an air-conditioned workspace equipped with computers, a microscope, digital camera, data transmission lines, and other amenities. This ‘portable’ team room compliments the team room in the Sugar Land, Tex., office.

The transmission system sends data and visuals between the two rooms. For example, team members in the office can view digital photos, taken through the microscope, as they review the LWD-mud log.

The onsite geoscience personnel also spend considerable time with the rig personnel to optimize drilling performance by improving understanding of the well geology.

Well design

Well design under the drilling excellence plan is an iterative process undertaken by the entire cross-functional team.

The methodology starts with a rigorous description of the geology, from the mud line to TD. The lithology, major geological events, pore pressure, fracture gradient, and other parameters are thoroughly studied and presented in a standard format to facilitate analysis.

Once the data have been analyzed, the drilling engineer drafts an initial well design, which is then reviewed by the entire team.

On very simple wells, the well design process occasionally takes only a single iteration.

But the typical design track for a deepwater well involves five or six iterations of the well design, with each iteration subject to team review, commentary, and revision.

It is through this multidimensional, cross-functional design and review process that we arrive at an optimized well design.

Perfect-well targeting

Rather than using past performance as a benchmark, Unocal approaches each new well with the aggressive goal of achieving perfect performance for that specific project. In most cases, this approach creates a dramatically different notion of what is possible to achieve.

The company uses ‘perfect-well targeting’ in a variety of ways, depending on the location and complexity of the well. Following are steps the company follows for the most complex wells.

To start the process, the engineer holds a meeting with the drilling foreman, superintendent, rig manager, and tool pusher. Using the optimum well design, this team breaks the execution plan down into as many as 400-500 separate elements. The team is charged with optimizing each piece, which it does by determining how quickly the steps can be completed, which steps can be done in parallel rather than sequentially, and which steps can be eliminated altogether.

Importantly, the team does not include any contingency time, waiting time, or preparation time in their plans. They consider only the time required to perform a task under ideal circumstances.

After creating the perfect-well target, the engineer meets with the functional drilling team (drilling foreman, superintendent, and rig manager) to review all steps in the plan and the time assigned to each.

Again, as with well design, it is an iterative process. The team looks for better ways to sequence the steps or perform tasks in parallel rather than in series.

For the time allocation, the functional team assesses the task, the equipment to be used, and the qualifications of the personnel who will perform the task. Only then do they finalize the time estimate for that step. Under no circumstance does the functional team compromise safety during the process of allocating time to each step.

At a prespud meeting, and throughout the well-plan execution, the team shares the perfect-well target and every associated step with the entire rig crew, including third-party vendor personnel. The functional team encourages rig-site personnel to review the target and provide suggestions for achieving it.

In this way, we conceptualize the perfect well, and use that as a benchmark for the project.

Risk management

Unocal has implemented standards and procedures to rigorously document the risks involved with each well and to communicate those risks to the entire team. The company manages the change process so that, as the well is drilled, the team can alter the well plan when events dictate.

This framework enables the team to react rapidly when circumstances change, analyze the new circumstances, change the well plan, document the change, and get approvalall in a short time frame.

The team implements plan changes in an organized, diligent, and well-documented fashion. In some instances, these change-management standards have made it possible for the team to gather, document the change, and gain approval in less than an hour.

Regardless of the team’s best efforts, it is rare for the company to drill a well completely according to plan. What is important, however, is how decisions are made and risks managed when the inevitable occurs, and the plan must change. Working from the drilling excellence standards and procedures, Unocal’s experience has shown that the company can carry out the decision-making process and resulting changes quickly, cost-effectively, and without compromising safety, when a departure from the plan becomes necessary.

Postwell documentation

Unocal considers postwell documentation and review an essential step. It helps improve team performance over time by enabling the team to learn from past experiences better and apply that knowledge to future situations.

Timely attention to this process is critical. Ideally, the core team should track performance and lessons learned on a daily basis.

A formal postwell review takes place to summarize and disseminate this information. The company solicits input from all core and extended team members, with an emphasis on candid discussions about performance that exceeded or fell short of the plan.

All of this information is documented and shared with other drilling teams within the Unocal drilling community to ensure that all of our drilling teams continuously learn.

Performance

Upon completion of this review of Unocal’s eight-point drilling excellence plan, technology is conspicuous by its absence. When all of the elements of a high-performance drilling culture are in place, the team is completely capable of choosing the right technology for the project at hand.

But, if the people factors and processes are not in place, the technology decision may become moot. Only when the emphasis is on people and processes first, and technology second, is breakthrough performance possible.

Such is the case with Unocal’s drilling operations off Indonesia and Thailand, on the Gulf of Mexico shelf, and in its deepwater province, where the high-performance drilling culture is baked into everything we do.

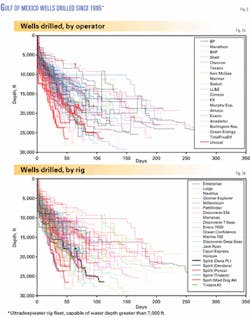

It was in the gulf’s deep waters that, in 15 months of operating the Transocean Sedco Forex Inc. Discoverer Spiritfrom commissioning through the drilling of six wellsUnocal’s drilling excellence philosophy delivered industry-leading performance, as shown in Figs. 2a and 2b.

Application of the drilling excellence approach and the advanced technology of the Discoverer Spirit drillship have proven a powerful combination. Indeed, sticking to established standards and processes has enabled Unocal to achieve results that far exceed even the aggressive marketing claims of the ship’s builders.

Unocal believes that its drilling performance provides compelling evidence that putting people and technology in their proper places produces breakthroughs in speed, results, safety, and value.

The author

Kevin S. O’Donnell is vice-president of drilling, procurement, and logistics for Unocal Corp., Sugar Land, Tex. He began his career at Exxon Co. USA in 1978, holding assignments in California and Alaska. He formed a California based independent oil and gas company in 1985. In 1990, O’Donnell joined Unocal, holding various assignments in California and Indonesia. In 1998, he moved to Texas to manage Unocal’s Deepwater Gulf of Mexico drilling program. He has a BS in petroleum engineering from the University of Southern California, Los Angeles.