New trunnion ball valves for pipeline service

New Series P3 trunnion-mounted ball valves are available in sizes 2-48 in. in ANSI 150-1500 ratings.

These forged body valves are designed to meet severe and demanding pipeline operations, and they meet API 6D, API 6A, API6FA fire-safe certification, API Q 1, and NACE MR01-75 standards.

Valves feature a three-piece bolted body design, which allows for flexibility, and the end configurations can be changed quickly to provide responsive service to oil and gas pipeline customers. A variety of enhancement features includes stem extensions, weld pups, valve automation, extended piping for buried service, and tar set coating.

The heart of the valves lies in the spring loaded seat design, which promises a tight seal at lower differential pressures allowing the line pressure to effect a piston action that forces the seat to the ball for a bubbletight seal, the company says.

Source: KF Industries Div., Circor International Inc., Box 95249, Oklahoma City, OK 73143-5249.

New hazardous gas sensor

The new Model 4107 Series smart sensor-transmitter (SST) is a stand-alone fixed-point hazardous gas sensor module. It promises accurate measurement of the applicable, digital display of gas concentration.

It features nonintrusive calibration, dual alarm relays, fault alarm, Modbus communications interface, and an industry standard linear 4-20 ma signal of gas concentration.

Alarm indication includes an LED indicator plus relay contacts for two gas concentration level alarms plus either a third alarm level or a fault alarm.

The two-line 32-character display provides menu prompting information for system configuration plus detailed information about gas concentration including engineering units and device tag name data.

The nonintrusive calibration feature enables the operator to calibrate the sensor in the field without declassifying the area. With the magnetic tool and the digital display, the user can step through the simple calibration process quickly and easily. The 4-20 ma signal can interface with most industry specific devices.

The bidirectional RS-232 and RS-485 Modbus protocol serial port enables communication along a serial bus data highway.

Gases detected include combustible gas, oxygen deficiency, carbon monoxide, hydrogen sulfide, chlorine, and sulfur dioxide.

Source: Sierra Monitor Corp., 1991 Tarob Court, Milpitas, CA 95035.

New drive head for well uses

The Moyno Ultra-Drive Model DD1 drive head is designed for use with Moyno downhole progressing cavity pumps in oil well production and gas well dewatering applications.

This electrically driven drive head has a maximum rating of 150 hp and features polished rod speeds up to 600 rpm and a 1,750 ft-lb torque rating on its recoil braking system.

The hollow shaft design helps simplify field mounting and installation, and a removable sealing system helps servicing and maintenance. The drive head can accommodate either 1 1/4 or 1 1/2 in. polished rods.

Source: R&M Energy Systems, 363 N. Sam Houston Parkway, Suite 950, Houston, TX 77060.

Process, instrument design software for plant design

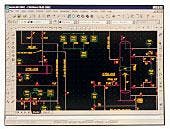

New CADWorx/P&ID Version 2002 is the latest edition of this firm’s AutoCAD-based software for creating process and instrumentation diagrams (P&ID) for piping plant design, now with enhanced links between the software and CADWorx/PIPE Version 2002 (OGJ, Apr. 22, 2002, p. 82).

These links make critical design information on the P&ID available to the CADWorx/PIPE model, helping to ensure that process diagram and model information are closely matched.

Other enhancements include new mutilanguage support allowing users to change command prompts, dialog boxes, and outputs to their own languages, and Tool Tips, which makes component information accessible any time by just passing the cursor over any item.

CADWorx/P&ID Version 2002 also includes enhanced process line source and destination functions to provide better links for process lines across drawings and adds an option that allows the software to check that an item placed on the diagram conforms to the currently set piping specification.

Also, newly rewritten context-sensitive help, documentation, and tutorials are easily accessible to help ensure the right answers and best solutions are available.

CADWorx/P&ID is part of a new generation software series offering full-featured 2D, 3D, isometric, and P&ID capabilities.

It, along with CADWorx/PIPE, provides intelligent drawing-data base connectivity, advanced levels of automation, easy-to-use drafting techniques, and a bidirectional link with analysis programs.

Source: Coade Inc., 12777 Jones Rd., Suite 480, Houston, TX 77070.