Equipment/Software/Literature

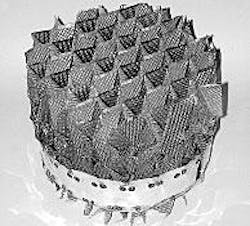

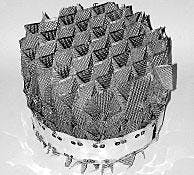

High-capacity structured packing for refinery uses

New Intalox 5TX is a sheet-metal-type structured packing designed for mass and heat transfer services requiring high liquid and vapor capacities.

It´s suited for refinery FCC main fractionators, atmospheric and vacuum crude columns, olefins plant water quench columns, and highly loaded absorbers and strippers in refining and chemical processing.

The new 5TX exhibits 20-33% greater capacity than other random and structured packings, the company says. The proprietary surface texture of Intalox structured packing means minimal loss in mass transfer efficiency, the firm points out.

Packing comes in a variety of metals and alloys, including stainless steels, titanium, and nickel alloys. Intalox structured packings are available in varying crimp heights and surface areas and in textured and smooth surfaces.

Source: Saint-Gobain NorPro Corp., Box 350, Akron, OH 44309-0350.

New one-step dry scrubber technology

A new technology called the Pahlman process captures NOx and SOx, selectively or simultaneously.

The company says the process has value for either natural gas-fired or coal-fired power plants because it can bring NOx and SOx emissions into environmental compliance without the high costs associated with conventional selective catalytic reduction (SCR) and flue gas desulfurization (FGD) technologies.

The firm says its process offers:

- Lower capital cost for dry scrubbing system than for either SCR NOx removal alone or for wet FGD SOx removal alone. Estimated savings are 30-50%. At coal-fired sites, the Pahlman Process can remove NOx and SOx in a single facility.

- Operating costs for dry scrubbing system that are lower than for either SCR NOx removal alone or for wet FGD SOx removal alone. Estimated savings range from 25%/year to 40%/year of operation and maintenance costs. The Pahlman Process does not use expensive catalysts, ammonia gas, or require operation of holding ponds. Further, the company notes, the process runs at a lower pressure drop than competing SCR and FGD systems.

- Elimination of hazardous materials handling and disposal problems. The process is true zero-ammonia-technology for NOx scrubbing. Also, it does not create contaminated gypsum as a by-product. There are no landfill issues.

- Yield of marketable industrial by-products. Nitrates and sulfates recovered during the regeneration of the Pahlmanite material can be sold.

- Higher NOx and SOx removal percentages. The dry Pahlman Process can remove up to 99% of NOx emissions or 99+% of SOx emissions from natural gas and coal-fired emission streams. At coal-fired sites, the process scrubbing has attained performance levels of 0.05 lb/MMbtu for NOx and 0.001 lb/MMbtu for SOx. At natural gas-fired sites, levels of 0.006 lb/MMbtu for NOx have been achieved. These higher levels may allow power plant owners/operators to sell NOx and SOx emissions credits into the marketplace, the firm points out.

Source: Enviroscrub Technologies Corp., 1650 W. 82nd St., Suite 650, Minneapolis, MN 55431.

Free catalog on internally gauged forced transducers

Free 104 page Catalog Volume 2 describes a line of force transducers.

Units include flat load cells, tension and compression of 250-2 mi11ion lb; clevis pins with 0-10 v dc and 4-20 ma outputs; tension links up to 400,000 lb; load sensing bolts and studs; and load indicators.

Source: Strainsert, 12 Union Hill Rd., West Conshohocken, PA 19428.

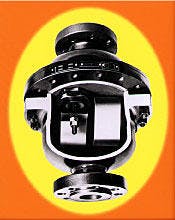

High capacity steam traps

The Magnum Series high capacity steam traps can be supplied with as many as 18 bimetallic elements for hot condensate flows as high as 149,000 lb/hr. Five models are available for differential pressures up to 320 psi.

The bimetallic element uses thermostatic and thermodynamic forces, helping to ensure optimal plant control with no loss of live steam. Among the features of this design: modulating discharge that automatically adjusts to operating pressure and load, stainless steel internals that are resistant to fatigue and corrosion, high cold discharge for fast start-up, and continuous air and C02 venting that helps maximize heat transfer while minimizing plant corrosion.

Traps are built to match your application, such as body size and pressure ranges. Connection sizes and types are custom matched to your specific application.

Traps come in sizes 11/2, 2, and 3 in. They feature a fabricated steel body and a selection of threaded (NPT), socket weld, or raised faced flanged end connections.

Source: Bestobell Steam Trap Div., Richards Industries, 3170 Wasson Rd., Cincinnati, OH 45209.