Life cycle analysis of water use and intensity of oil and gas recovery in Wattenberg field, Colo.

Stephen Goodwin

Ken Carlson

Colorado State University

Fort Collins, Colo.

Caleb Douglas

Ken Knox

Noble Energy Inc.

Denver

Efficiency, particularly in the western US, is an increasingly important priority to meet an increasing water resource demand. Even though the oil and gas industry has long been a part of the economy in Colorado and the West, recent technological advances have stimulated growth in oil and gas development and operations and therefore have increased the industry's need for water resources.

This study provides an analysis of the volume of water required for unconventional shale gas and shale oil development and how efficiently the water is used. A general material balance is used to assess the life cycle of water and energy resources of 445 Noble Energy Inc. wells in Wattenberg field in northeastern Colorado.

Water use data as well as oil and gas production data were collected from Noble Energy wells and separated by well type (horizontal or vertical) and water use (drilling and hydraulic fracturing).

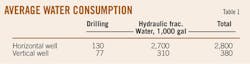

Vertical and horizontal wells operated by Noble Energy in Wattenberg during 2010 and 2011 consumed an average of 380,000 and 2,800,000 gal of water, respectively. On average, vertical wells used 77,000 gal to drill and an additional 310,000 gal to hydraulically fracture the well; whereas, horizontal wells used 130,000 gal to drill and 2,700,000 gal for hydraulic fracturing.

A decline curve analysis was used to estimate the ultimate recovery from each individual well. Exponential and harmonic decline curves were fit to the production data to project low and high production scenarios, respectively.

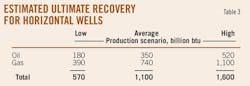

Vertical wells are expected to have an EUR between 24 billion and 60 billion btu for oil and between 32 billion and 84 billion btu for gas. Horizontal wells are expected to have an EUR between 390 billion and 1,100 billion btu for gas and between 180 billion and 520 billion btu for oil.

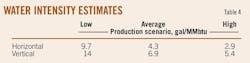

A ratio of the water consumed and the EUR for each well was used to estimate the water intensity of each well. Vertical wells have an expected water intensity ranging between 5.4 and 14 gal/MMbtu, and horizontal wells have an expected water intensity value between 2.9 and 9.7 gal/MMbtu.

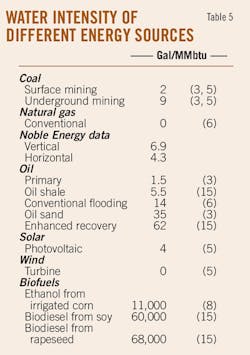

When the water intensity of shale gas extraction was compared to other energy sources it was found to be one of the lowest. The average horizontal well in Wattenberg field consumed 4.3 gal/MMbtu, which is comparable with 4 gal/MMbtu for solar photovoltaic energy. In contrast, energy produced from underground coal requires 9 gal/MMbtu, and the amount of water consumed for energy produced from biofuels escalates to 11,000 to 68,000 gal/MMbtu.

Horizontal wells require more water for hydraulic fracturing than vertical wells, on average. However, the water intensity is slightly lower for horizontal wells because the water is used in a more efficient manner.

Introduction

Water resources in Colorado and the western US are constantly strained given the historical agricultural needs, burgeoning development, and the semiarid environment.

With continued population increases and the importance of agriculture to the overall economy, the pressure on water and other natural resources is expected to intensify. Even though the oil and gas industry has long been a part of the economy in Colorado and the West, recent technological advances have stimulated considerable growth in oil and gas development and operations and therefore have increased the industry's need for water resources.

Competition over water resources will continue to escalate to meet expanding municipal and industrial demands, including those associated with the oil and gas industry. In October 2011 the State Review of Oil and Natural Gas Environmental Regulations (STRONGER) organization issued a report on the Colorado hydraulic fracturing program and the rules developed by the Colorado Oil and Gas Conservation Commission (COGCC) related to this.1 The report, which was generally positive, made five recommendations for improvement. One of the key recommendations in this report was regarding the availability of water:

"The review team recommends that the COGCC and the DWR jointly evaluate available sources of water for use in hydraulic fracturing. Given the significant water supply issues in this arid region, this project should also include an evaluation of whether or not availability of water for hydraulic fracturing is an issue and, in the event that water supply is an issue, how best to maximize water reuse and recycling for oil and gas hydraulic fracturing."

Other recommendations regarding the management of water resources associated with hydraulic fracturing were made by the Natural Gas Subcommittee of the Secretary of Energy's Advisory Board (SEAB) in November 2011.2 The subcommittee was charged in April 2011 to study ways to improve the safety and environmental performance of natural gas hydraulic fracturing from shale formations.

In its final report, the subcommittee stated, "At present, neither the Environmental Protection Agency (EPA) nor the states are engaged in developing a systems/life cycle approach to water management." They recommend that new partnerships or mechanisms be developed to study the life cycle of water resources as one approach to protecting the quality of water resources in the future.2

Gleick3 provided one of the first broad reviews of water intensity, presenting direct, consumptive water intensity values for each life cycle phase (i.e., mining, fuel preparation, generation, etc.) of several different fuel sources in 1994. Sovacool and Sovacool4 expanded the scope of a water intensity analysis to separate water use into both water withdrawals and consumption.

Fthenakis and Kim5 were the first to include upstream water use in the analysis, which includes water requirements associated with energy and material inputs to each life cycle phase of electricity generation technologies.

In recent years, increasing concern about water and energy resources in the US has led to significantly more research and associated reports, particularly from government agencies,6-14 most notably, a 2006 report to Congress from the Department of Energy.6 The report was a response to a Congressional directive asking for "a report on energy and water interdependencies, focusing on threats to national energy production that might result from limited water supplies."

Perhaps the most comprehensive and recent review of water intensity comes from the Harvard Kennedy School, titled "Water Consumption of Energy Resource Extraction, Processing, and Conversion."15

Several regional studies12-14 16-18 have assessed water resource challenges with increasing demands for water. The majority of these studies provide a broad estimate of water requirements, without a detailed analysis of water use on an individual well basis. An analysis of the water intensity of each individual well provides a more detailed and accurate assessment of the water intensity. Other studies focus solely on electricity generation7 10 19-25 or transportation,26-28 the two largest energy sectors in the US.

The project described in this report is the first step in addressing the concerns raised and gaps in other studies. A framework is proposed to assess the life cycle of water and energy resources of Noble Energy wells in Wattenberg field in northeastern Colorado. Data from Noble Wattenberg wells are used to assess the overall water use and average water intensity in the region as a first application of the general framework.

The specific objectives of this project are to: (1) determine water use associated with Noble Energy wells in Wattenberg field and delineate them with respect to well type (horizontal or vertical) and water use (drilling or hydraulic fracturing); and (2) determine the water intensity of each well and compare with other energy sources.

Methodology

Data collection

To best assess current water use and predict future water needs, sampled wells were limited to those completed in 2010 and 2011 by Noble Energy in Wattenberg field.

Older wells that have been refractured to stimulate recovery were not included in the assessment of wells since this circumstance is not equivalent to fracturing a newly drilled well. The issue of refracturing wells and the associated water consumption and water intensity should be included in future studies.

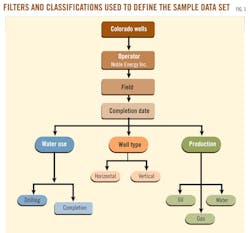

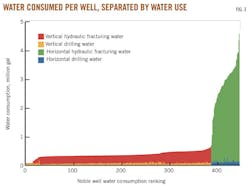

Water consumption and energy production data were collected and separated by well type and water use (Fig. 1). The final sample includes 386 vertical wells and 59 horizontal wells. This 445-well data set represents all of the wells in 2010 and 2011 with complete water consumption and energy production records. A total of 883 wells was drilled in 2010 and 2011 and the remaining 438 wells were omitted for a variety of reasons; most did not have water consumption or production data readily available.

Noble Energy collected water consumption values using the patented WellView program (Peloton Computer Enterprises Ltd., Houston). WellView is part of the Peloton suite of software used for collecting and organizing oil field data. Drilling and hydraulic fracturing reports are added to WellView by a Noble Energy employee that is on site at each drilling and hydraulic fracturing site.

The water consumption totals are verified by Noble Energy's accounting department, and any conflict of values between the field operations and the accounting department is reconciled using the WellView program. All of the water consumption data were accessed in November 2011.

Wells were classified as either horizontally or vertically drilled. Directional and deviated wells are classified as vertical wells. Less horizontal well data were acquired because the technology has only recently been adapted to Wattenberg field. The final water consumption data set includes water consumed and energy recovered from 386 vertical wells and 59 horizontal wells and categorized as either drilling water or completion water.

Material balance

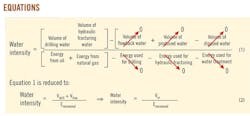

Water intensity is defined as the ratio of water consumed and energy recovered and is used to measure how efficiently a water resource is used.

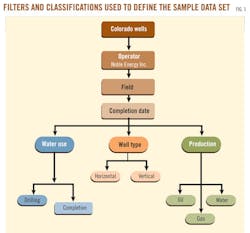

For this study, a materials and energy balance approach was used to determine the net water consumed and net energy recovered for each well. A schematic shows the water and energy flows and the boundary used to define the water intensity (Fig. 2).

The water intensity discussed in this article incorporates only the water consumed and energy produced. The amount of water and energy consumed in drilling and hydraulic fracturing that is offset by flowback and produced waters that are treated and recycled into the production stream warrant additional research as these technologies are developed and applied.

It is assumed that the energy used in drilling and hydraulic fracturing is negligible compared with the amount of energy recovered, and none of the flowback or produced water is reused. General equations for the water intensity can be developed for the water intensity (see box with Equations 1 and 2).

Results

Water consumption

On average, each vertical and horizontal well used an average of 380,000 and 2,800,000 gal of water, respectively.

Vertical wells used an average of 77,000 gal to drill and an additional 310,000 gal to hydraulically fracture each well. Horizontal wells used an average of 130,000 gal to drill and an additional 2,700,000 gal to hydraulically fracture each well.

Fig. 3 arranges each sampled well from least to greatest, in terms of total water consumption. The bars are color coded by well type and water use. Table 1 shows the average water consumption of each well type and water use.

Water consumption values of horizontal wells are significantly more than water consumption values of vertical wells. The increased drilling distance of horizontal wells and an increased number of hydraulic fracturing stages contribute to the increased water requirements.

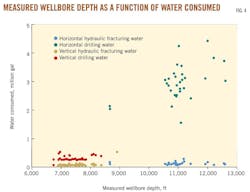

A subset of wells was chosen to determine if a correlation between the measured wellbore depth and water uses (e.g., drilling water consumption or hydraulic fracturing water consumption) exists. No clear correlation was found (Fig. 4).

Ultimate energy recovery

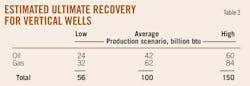

Vertical wells are estimated to have an ultimate recovery between 56 billion and 150 billion btu with approximately 60% of the energy from gas, and horizontal wells are estimated to have an ultimate recovery between 570 billion and 1,600 billion btu with 70% of the energy from gas.

Tables 2 and 3 show the energy recovery for each well type, energy source, and recovery scenario.

A wide range of EURs is presented because the long-term performance of unconventional oil and gas wells is not well understood and less than 2 years of data are used for the decline curve analysis. As recovery rates are better understood and additional production data is available, the EUR values can be estimated with more precision.

Water intensity

Horizontal wells are estimated to have a water intensity value between 2.9 and 9.7 gal/MMbtu, and vertical wells are estimated to have a water intensity value between 5.4 and 14 gal/MMbtu (Table 4).

Despite much lower water requirements for vertical wells, horizontal wells have lower water intensity requirements for all energy production scenarios. These results indicate that horizontal drilling and hydraulic fracturing is a more efficient approach for oil and gas extraction than older methods have been.

When the water intensity associated with recovery is compared with other energy sources, unconventional oil and gas recovery in Wattenberg field is found to be comparable with solar energy (Table 5).

Although only a simplified version of the material balance framework presented in this study was applied in this study, it can be used to assess recycling and reuse of flowback and produced water and the energy requirements of these processes.

The degree of treatment of flowback and produced water will determine the amount of water available for reuse, additional energy requirements for treatment, and best practices for life cycle water management and disposal. Also, the material balance of an entire region can be assessed for the complete life cycle of the wells to quantitatively determine the long-term impact on water resources.

Summary

Vertical and horizontal wells operated by Noble Energy in Wattenberg during 2010 and 2011 consumed an average 380,000 and 2,800,000 gal of water.

Despite the much higher quantities of water used for horizontal wells, the efficiency of this energy extraction practice was found to be greater than with vertical drilling and hydraulic fracturing.

Vertical and horizontal wells operated by Noble Energy in Wattenberg during 2010 and 2011 were determined to have an expected average water intensity of 6.9 and 4.3 gal/MMbtu, respectively. Vertical wells have an expected water intensity ranging between 5.4 and 14 gal/MMbtu, and horizontal wells have an expected water intensity value between 2.9 and 9.7 gal/MMbtu.

The water intensity of these oil and gas extraction techniques when compared with other energy sources was found to be one of the lowest.

The average Noble Energy horizontal well in Wattenberg field retains a water intensity of 4.3 gal/MMbtu, which is comparative with photovoltaic solar energy at 4 gal/MMbtu. Only wind (0 gal/MMbtu) and primary oil recovery (1.5 gal/MMbtu) are significantly lower. In contrast, the water intensity for energy produced from underground coal is 9 gal/MMbtu and escalates to 16,000 to 45,000 gal/MMbtu for energy produced by biofuels.

Acknowledgments

The project was funded by the Colorado Energy Water Consortium (http//cewc.colostate.edu).

References

1. STRONGER, "Colorado hydraulic fracturing state review, technical report," STRONGER: State Review of Oil and Natural Gas Environmental Regulations, October 2011.

2. SAEB, "Shale gas production subcommittee second 90-day report," technical report, US Department of Energy, November 2011.

3. Gleick, Peter H., "Water and energy," Annual Review of Energy and the Environment, Vol. 19, No. 1, 1994, pp. 267-99.

4. Sovacool, Benjamin K., and Sovacool, Kelly E., "Preventing national electricity-water crisis areas in the US," technical report, Energy Governance Program at the Centre on Asia and Globalization, Lee Kuan Yew School of Public Policy at the National University of Singapore, 2009.

5. Fthenakis, Vasilis, and Kim, Hyung Chul, "Life-cycle uses of water in US electricity generation," Renewable and Sustainable Energy Reviews, Vol. 14, No. 7, 2010, pp. 2,039-48.

6. US Department of Energy, "Energy demands on water resources," technical report, US Department of Energy, 2006.

7. US Department of Energy, "Estimating freshwater needs to meet future thermoelectric generation requirements," Technical Report 400/2008/1339, DOE and National Energy Technology Laboratory, September 2008.

8. US Department of Energy, "State oil and natural gas regulations designed to protect water resources," technical report, US DOE, Office of Fossil Energy, National Energy Technology Laboratory, May 2009.

9. Clark, C.E., and Veil, J.A., "Produced water volumes and management practices in the US," technical report, Argonne National Laboratory prepared for US DOE, Office of Fossil Energy, National Energy Technology Laboratory, September 2009.

10. National Energy Technology Laboratory, "Estimating freshwater needs to meet future thermoelectric generation requirements: 2009 update," technical report 400/2009/1339, NETL, US DOE, September 2009.

11. National Energy Technology Laboratory, "Emerging issues for fossil energy and water," technical report, NETL, US DOE, 2006.

12. Government Accountability Office, "Energy-water nexus: Improvements to federal water use data would increase understanding of trends in power plant water use," technical report, US GAO, 2009.

13. Colorado Water Conservation Board, "State of Colorado 2050 municipal and industrial water use projections," technical report, CWCB, Camp Dresser and McKee Inc., Harvey Economics, July 2010.

14. Colorado River Basin Roundtable and Yampa/White River Basin Roundtable, "Energy development water needs assessment phase ii," technical report, Colorado Water Conservation Board, February 2011.

15. Mielke, Erick, Anadon, Laura Diaz, and Narayanamurti, Venkatesh, "Water consumption of energy resource extraction, processing, and conversion," Discussion Paper 2010-15, Harvard Kennedy School Belfer Center for Science and International Affairs, Cambridge, Mass., October 2010.

16. Fisher, Jeremy, and Ackerman, Frank, "The water-energy nexus in the western US: Projections to 2100," technical report, Stockholm Environment Institute, February 2011.

17. CDM Inc., "Colorado's water supply future: State water supply initiative 2010," technical report, Colorado Water Conservation Board, January 2011.

18. Stacy Tellinghuisen, "Water conservation = energy conservation," a report for the CWCB, Western Resource Advocates, June 2009.

19. Domenichini, Rosa, Arienti, Silvio, Cotone, Paolo, and Santos, Stanley, "Evaluation and analysis of water usage and loss of power in plants with CO2 capture," Energy Procedia, Vol. 4, 2011, pp. 1,925-32.

20. Gerdes, Kristin, and Nichols, Christopher, "Water requirements for existing and emerging thermoelectric plant technologies," technical report DOE/NETL-402/080108, National Energy Technology Laboratory, April 2009.

21. Hightower, Mike, "Energy and water: Issues, trends, and challenges," EPRI workshop, Sandia National Laboratories, July 2008.

22. Inhaber, Herbert, "Water use in renewable and conventional electricity production," Energy Sources, Vol. 26, 2004, pp. 309-22.

23. Larson, Dana, Lee, Cheryl, Tellinghuisen, Stacy, and Keller, Arturo, "California's energy-water nexus: Water use in electricity generation," Southwest Hydrology, September/October 2007, pp. 20-30.

24. Stillwell, Ashlynn S., King, Carey, W., Webber, Michael E., Duncan, Ian J., and Hardberger, Amy, "The energy-water nexus in Texas," Ecology and Society, Vol. 16, No. 1, 2011.

25. Yang, Xiaoying, and Dziegielewski, Benedykt, "Water use by thermoelectric power plants in the US," Journal of American Water Resources Association, Vol. 43, No. 1, February 2007, pp. 160-69.

The authors

Ken Carlson ([email protected]) is an associate professor in Civil and Environmental Engineering at Colorado State University and cofounder with Noble Energy authors of the Colorado Energy Water Consortium (http://cewc.colostate.edu). He has a BS in chemical engineering from the University of Wisconsin-Madison, MS in environmental engineering from CSU, and a PhD in environmental engineering from the University of Colorado-Boulder.

Caleb Douglas is an environmental engineer at Noble Energy Inc. specializing in water management. He has BS and MS degrees in environmental engineering from CSU.

Ken Knox is a senior advisor for Noble Energy and is responsible for strategic planning and management of the company's comprehensive full life cycle water program. He has a BS in chemical engineering and MS and PhD degrees in civil engineering, all from CSU.

More Oil & Gas Journal Current Issue Articles

More Oil & Gas Journal Archives Issue Articles

View Oil and Gas Articles on PennEnergy.com