Shaghayegh Khalaji

National Iranian Gas Co.

Tehran

Economic analyses demonstrate the operational benefits of using particular energy recovery and scrubber technologies on natural gas transmission systems. The first article of this series, presented here, details these analyses as applied to Iran's gas system. The concluding article will focus on the effect of scrubbers and other equipment in attempting to maximize capital return.

Background

Iran is one of the largest consumers of natural gas in the world. Several transmission pipelines move natural gas across the country, with compressor stations roughly 100 km apart. Existing information regarding gas consumption by compressor stations in Europe cannot be directly applied to Iranian stations due differences in line length and the need to first define a number of consumption indices.

Displaying 1/4 Page 1, 2, 3, 4

View Article as Single page

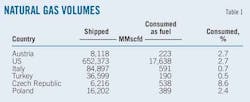

Table 1 shows the energy consumed transmitting gas in some countries.

Comparison, however, requires development of suitable indices. This article compares the power required for gas transfer via pipeline by first calculating the power needed by each station per 1 million cu m gas/km/day.

Table 2 shows this power index for a variety of countries.

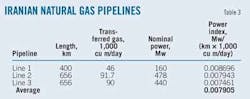

Table 3 shows the calculated power requirement for gas transfer of 1 million cu m gas/km/day on three Iranian pipeline networks. Iranian power requirement are about 60% more than the other countries.

Investigation parameters

The classic definition of efficiency of thermodynamic systems centers on increasing energy per unit of consumed fuel. Increases in either pressure or temperature can increase the power produced by compressor stations. Pressure is a desired increase in this context, temperature is not.

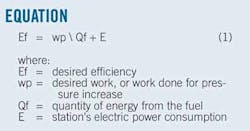

Equation 1 defines desired efficiency, an index for comparing different stations.

Calculating required power involves extracting enthalpy of output gas pressure and input gas temperature from thermodynamic tables and determining gas flow rate. Thermal efficiency and energy wasted in different sections of the compressor are part of this calculation.

Displaying 1/5 Page1, 2, 3, 4, 5Next>

View Article as Single page