Shell advances Appalachian petrochemical project

Royal Dutch Shell PLC subsidiary Shell Chemical Appalachia LLC has taken final investment decision to build a grassroots petrochemical complex about 30 miles northwest of Pittsburgh that will produce ethylene and polyethylene (PE) from low-cost Marcellus and Utica shale ethane (OGJ Online, Nov. 7, 2014).

Main construction on the complex will begin in about 18 months, with commercial production scheduled for startup early in the next decade, Shell said.

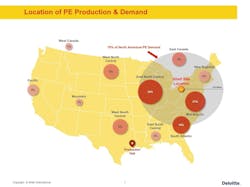

To be located on the banks of the Ohio River in Potter Township, Beaver County, Pa., the complex’s close proximity to gas feedstock will enable shorter and more dependable supply chains vs. supplies from the US Gulf Coast to North American PE customers, more than 70% of which are located within a 700-mile radius of Pittsburgh, Shell said.

The company did not disclose details regarding its proposed investment for the project.

FID on the project follows Pennsylvania’s Department of Environmental Protection’s approval last year of an air quality plan permit that allows Shell to build and temporarily operate the petrochemical complex until June 18, 2019 (OGJ Online, June 23, 2015).

First announced in 2011 (OGJ Online, June 6, 2011), Shell’s Appalachian petrochemical complex will include an ethane cracker with an average ethylene production capacity of about 1.5 million tonnes/year, three PE units with a combined production of 1.6 million tpy, as well as associated installations for power and steam generation, storage, logistics, cooling water and water treatment, emergency flare, and offices.

The Appalachian petrochemical complex will be the third major project Shell recently has advanced to expand and strengthen its chemicals business.

Earlier this year Shell Chemical LP started construction on a $717-million project to increase alpha olefins (AO) production at its Geismar, La., chemical manufacturing plant by 425,000 tpy to an overall 1.3 million tpy by early 2018 (OGJ Online, Feb. 16, 2016; Nov. 30, 2015).

Shell subsidiary Shell Nanhai BV and partner China National Offshore Oil Corp. (CNOOC) also recently reached FID on a plan to expand capacity at their 50-50 joint venture CNOOC & Shell Petrochemicals Co. Ltd.’s petrochemical complex in the Daya Bay Economic and Technological Development Zone, Huizhou, Guangdong Province, China (OGJ Online, Mar. 22, 2016; Dec. 15, 2015).

Alongside continuing construction of an ethylene cracker and ethylene derivatives units that will increase ethylene capacity by more than 1 million tpy, or about double the complex’s current capacity (OGJ Online, Dec. 20, 2013), the expansion also includes construction of what will be China’s largest styrene monomer and propylene oxide (SMPO) plant.

The expanded Chinese complex, once completed, will use Shell’s proprietary OMEGA, SMPO, and Polyols technologies for the first time in China to produce the following: ethylene oxide, 150,000 tpy; ethylene glycol, 480,000 tpy; and high-quality polyols, 600,000 tpy.

Contact Robert Brelsford at [email protected].